Spiral-structure string and manufacturing method

A technology of a helical structure and a manufacturing method, applied in the field of helical structure rope and its manufacturing, can solve the problems of single appearance, inability to meet requirements, limited decorative effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

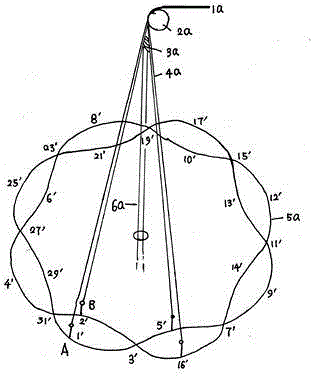

[0027] The spiral structure cord of the present invention is manufactured as follows.

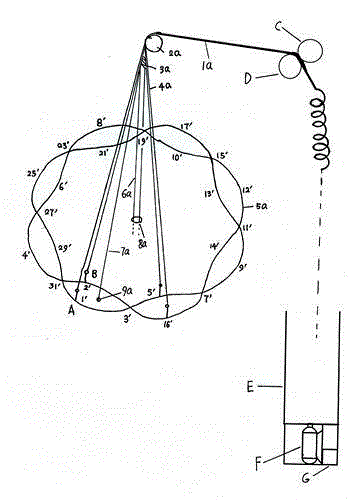

[0028] The manufacturing method of the spiral structure rope belt of the present invention is in figure 1 On the basis of, add glue wire 7a, core rope input port 8a, glue wire input port 9a, upper output guide wheel C, lower output guide wheel D, receiving bucket E, motor F and speed governor G. The yarn 4a, the core rope 6a, and the rubber filament 7a are woven into a rope in the interweaving area 3a. When the finished rope 1a comes out of the rope take-up device 2a, it passes through the upper output guide wheel C and the lower output guide wheel D and falls into the receiving bucket E. The upper output guide wheel C and the lower output guide wheel D exert traction on the spiral structure rope belt, and actively introduce the spiral structure rope belt into the receiving bucket E.

[0029] Further, a motor F is installed at the bottom of the receiving barrel E, and the motor F rotates clockwi...

Embodiment 2

[0032] It is manufactured according to the method of Example 1, and the specific data is: 16 300D polyester filaments on the periphery + No. 23 rubber filaments + 3mm diameter soft core rope.

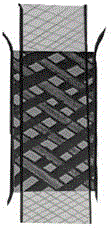

[0033] Weaving effect like Figure 4 As shown, because the core rope is soft and thin, and there is only one glue wire, the spiral structure rope belt has a thinner cross-section diameter, a soft hand feel, a larger pitch, and lower elasticity.

Embodiment 3

[0035] It is manufactured according to the method of Example 1, and the specific data is: 32 300D polyester filaments on the periphery + 2 No. 23 rubber filaments + 4mm diameter hard core rope.

[0036] Weaving effect like Figure 5 As shown, due to the increase in the number of outer polyester filaments, the core rope is thicker and harder, and two rubber threads are added. The spiral structure rope has a thicker cross-sectional diameter, a harder feel, a smaller pitch, and overall elasticity. Significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com