A light-weight, high-strength, cement-free assembled wall and floor decorative board and paving method

A decorative board and cement-free technology, which is applied in the field of decorative materials, can solve the problems of difficult installation and construction, increase building load, occupy space, etc., and achieve the effects of simple, fast and clean installation, saving building space, and reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

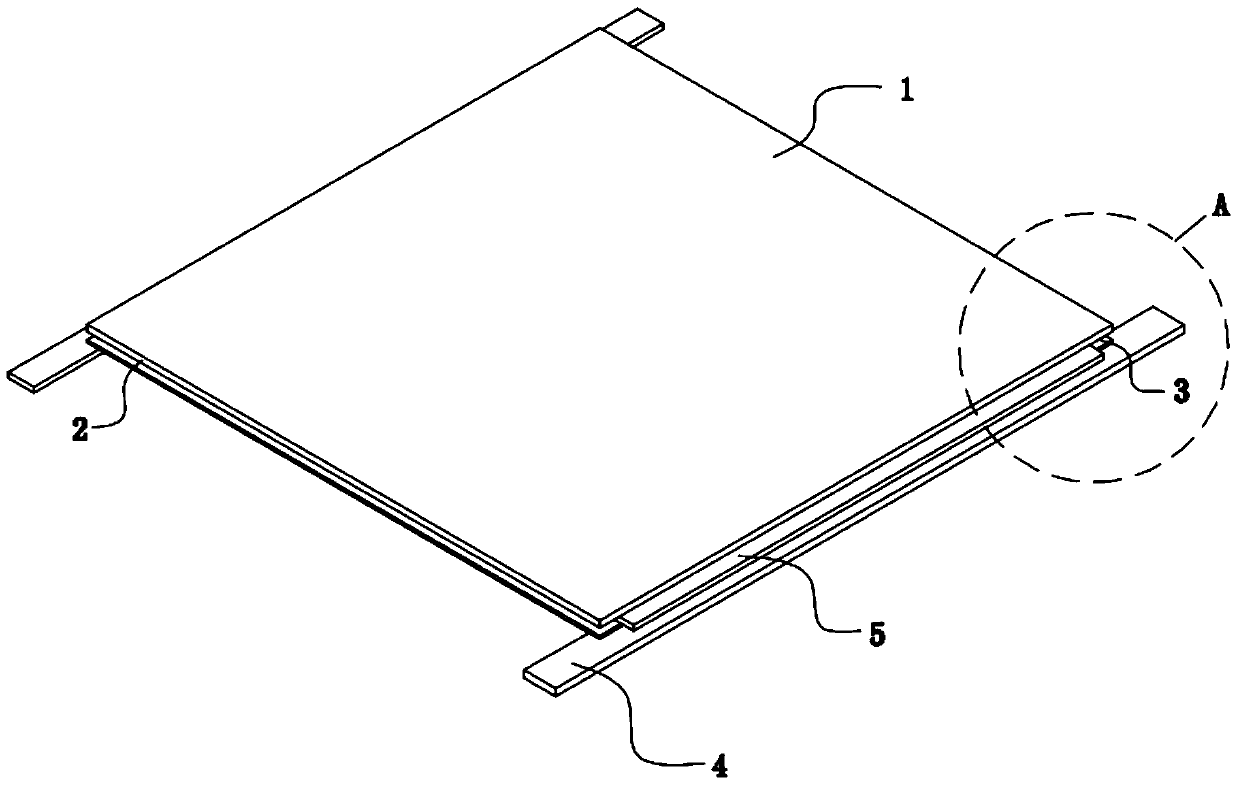

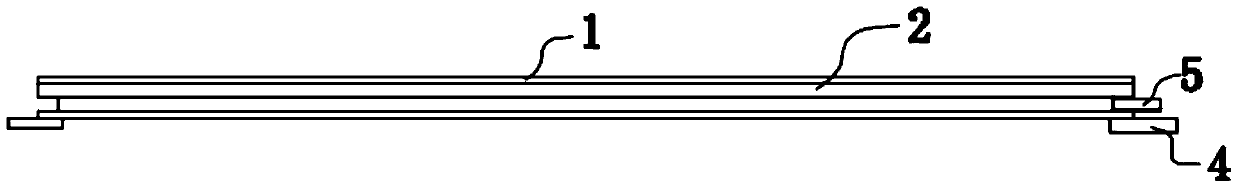

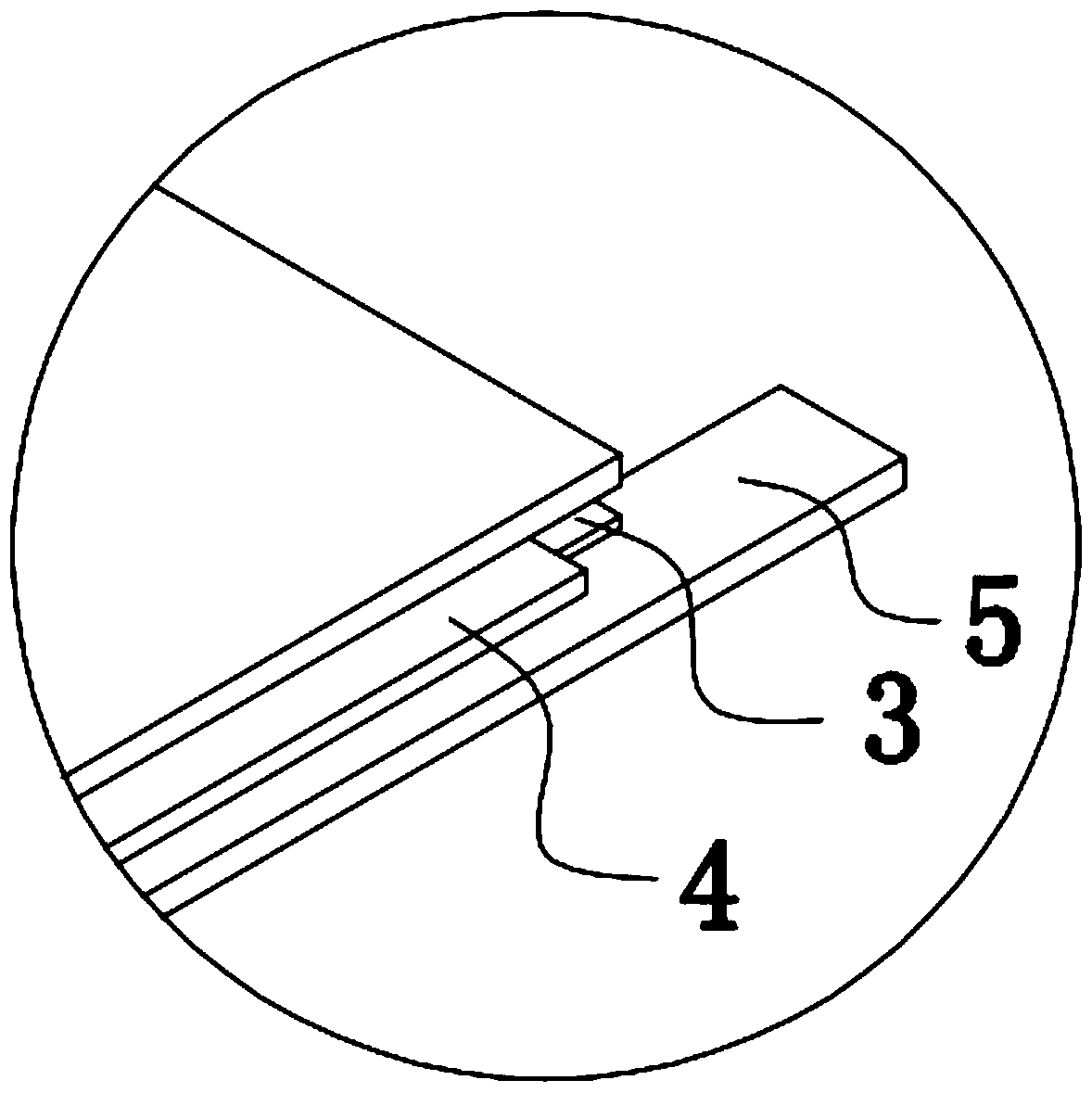

[0028] like Figure 1 to Figure 3 As shown, the light-weight, high-strength, cement-free assembled wall and floor decorative board of this embodiment includes a surface layer 1. The surface layer 1 in this embodiment is an artificial quartz slate, and the back side of the surface layer 1 is provided with a plastic plate 2. The side of the plastic plate 2 is provided with an assembly groove 3 , and the back of the plastic plate 2 is provided with a connecting pad 4 .

[0029] Specifically, in this embodiment, inwardly recessed assembly grooves 3 are provided on the four sides of the plastic plate 2, and the connecting clips 5 can be plugged into each assembly groove 3. The connecting clips 5 in this embodiment It is a long strip with a rectangular cross section, the connecting clip 5 extends in the same direction as the assembly groove 3, and the width of the connecting clip 5 is greater than the depth of the assembling groove 3, that is, when the connecting clip 5 is installed...

Embodiment 2

[0038] like Figure 4 to Figure 6 As shown, in this embodiment, the plastic plate 2 and the surface layer 1 are in the shape of a square block, the surface layer 1 in the present embodiment is a ceramic plate or a ceramic sheet, and the assembly groove 3 is arranged on the grooved profile 6, it needs to be explained What’s more, the grooved profile 6 in this embodiment is directly plugged into the preset groove of the plastic plate 2. In other embodiments, the grooved profile 6 can be pasted on the edge of the plastic plate 2 or other structures. I won't repeat them here. Adopting such a structure is conducive to the production and manufacture of the plastic board 2 and the surface layer 1. After the production is completed, the plastic board 2 and the grooved profile 6 can be individually packaged and transported to the site, and the installation can be completed on site, which is not only conducive to protection The assembly groove 3 is not damaged, and is convenient for tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com