Power transmission tower

A technology for transmission towers and tower bodies, applied in the field of self-supporting transmission towers, which can solve the problems of poor bearing performance, inconvenient construction, and high cost of transmission towers, and achieve the effects of increasing bearing capacity, reducing construction costs, and improving pressure capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

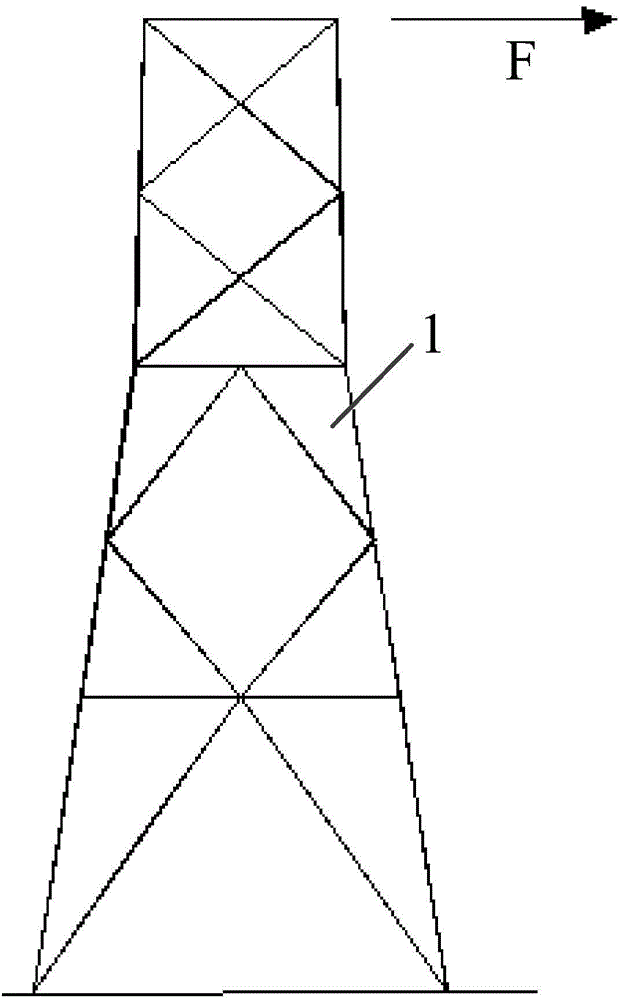

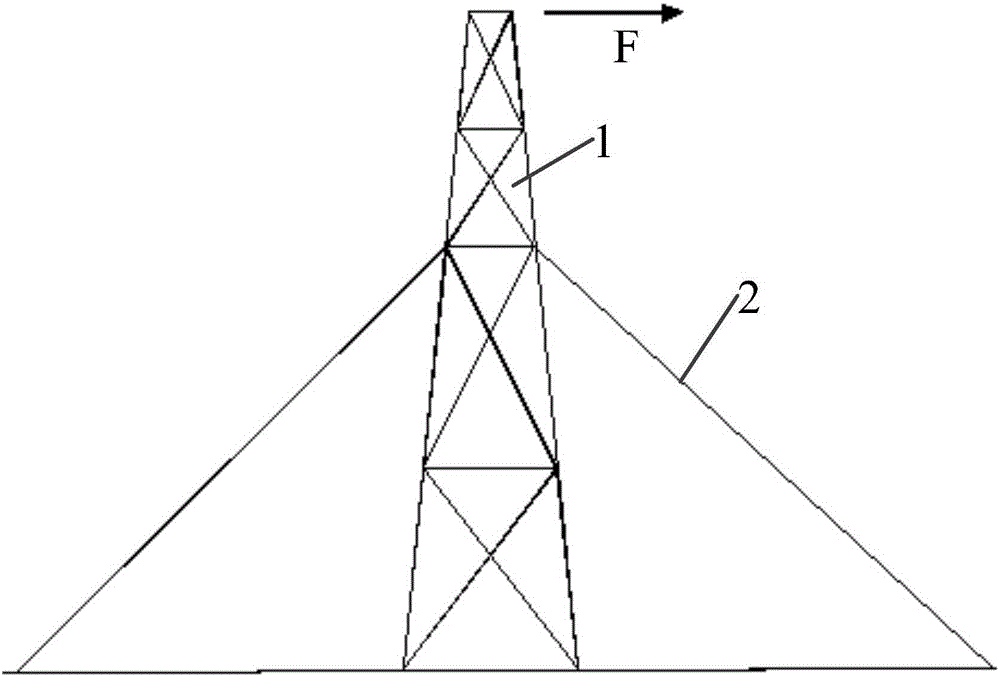

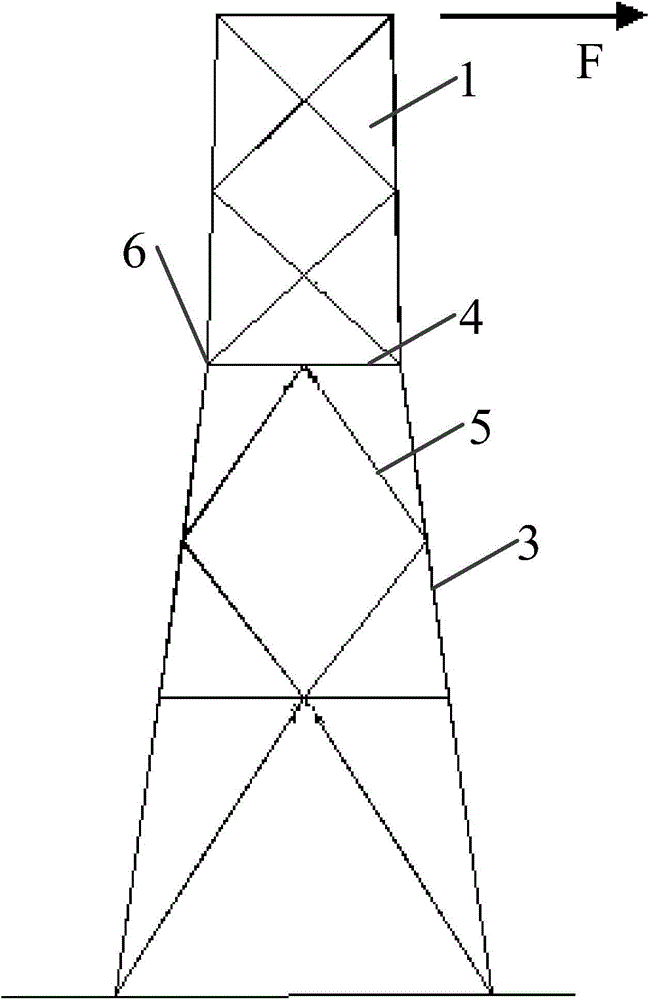

[0034] Such as image 3 As shown, a power transmission tower includes a vertically arranged tower body 1 and a cross arm arranged horizontally on the tower body. The tower body 1 is a frame structure formed by interlacing main materials 3, horizontal materials 4 and oblique materials 5. The connection point between the main material 3 and the cross material 4 is a node 6 .

[0035] The four main materials 3 are distributed at 90 degrees on the horizontal plane, and the nodes 6 form a hexahedron whose upper and lower sides are rectangular.

[0036] Node 6 forms a square diaphragm on the same plane.

[0037] The number of transverse partitions is two, and the transmission tower is divided into three floors.

[0038] The two ends of the oblique material 5 are respectively connected with the adjacent main material 3 and the horizontal material 4 to form a diagonal bracing surface;

[0039] The main material 3 and the horizontal material 4 are steel pipes filled with concrete. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com