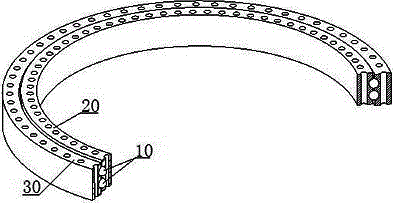

Method of improving double-row-contact ball-type revolve-bearing force situation

A technology of bearing force and contact ball, applied in the design field of contact ball slewing bearing, can solve the problem of uneven distribution of contact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

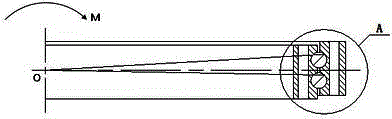

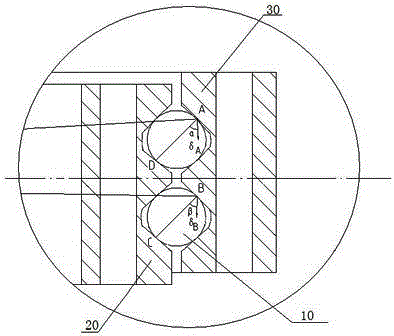

[0031] like Figure 4 As shown, assume that the inner ring 2 is fixed, and the outer ring 3 rotates clockwise relative to the inner ring 2. At this time, the overturning moment is transmitted by the outer ring. With the support center O as the center of the circle, the steel ball 1 is placed on the raceway profile of the outer ring. Any initial contact point on 5 (point B in this example, the contact angle at the initial contact point on the general support is 45°) and the distance from the center O is a radius to draw an arc, which is in line with the surface of the steel ball All the intersection points are all the contact points A', H, B, and F of the outer ring on the required steel ball, and the connection line between any contact point of the outer ring and the contact point of the inner ring corresponding to the force transmission passes through the center of the steel ball , all the inner ring contact points D', G, C, E on the steel balls can be determined in turn, and...

Embodiment 2

[0035] like Figure 5As shown, assume that the outer ring 3 is fixed, and the inner ring 2 rotates clockwise relative to the outer ring 3. At this time, the overturning moment is transmitted by the inner ring, with the support center O as the center of the circle, and the inner ring raceway type of the steel ball 1. The distance between any initial contact point on line 4 (point C in this example) and the center O is the radius to draw an arc, and all intersections between the arc and the surface of the steel ball are the contact points G of all inner rings on the steel ball. , D, E, C, and the connection line between any contact point of the inner ring and the contact point of the outer ring corresponding to the force transmission passes through the center of the steel ball, and all the contact points H and A' of the outer ring on the steel ball can be determined in turn , F, B, adjust the position of the raceway profile line of the inner ring on the inner ring so that it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com