Chain type braking device of heavy vehicle

A brake device and technology for trucks, applied in the direction of brake parts, brake discs, brake types, etc., can solve the problems of longer braking distance, incomplete return, and low reliability, so as to reduce the amount of maintenance, Reduced braking time and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

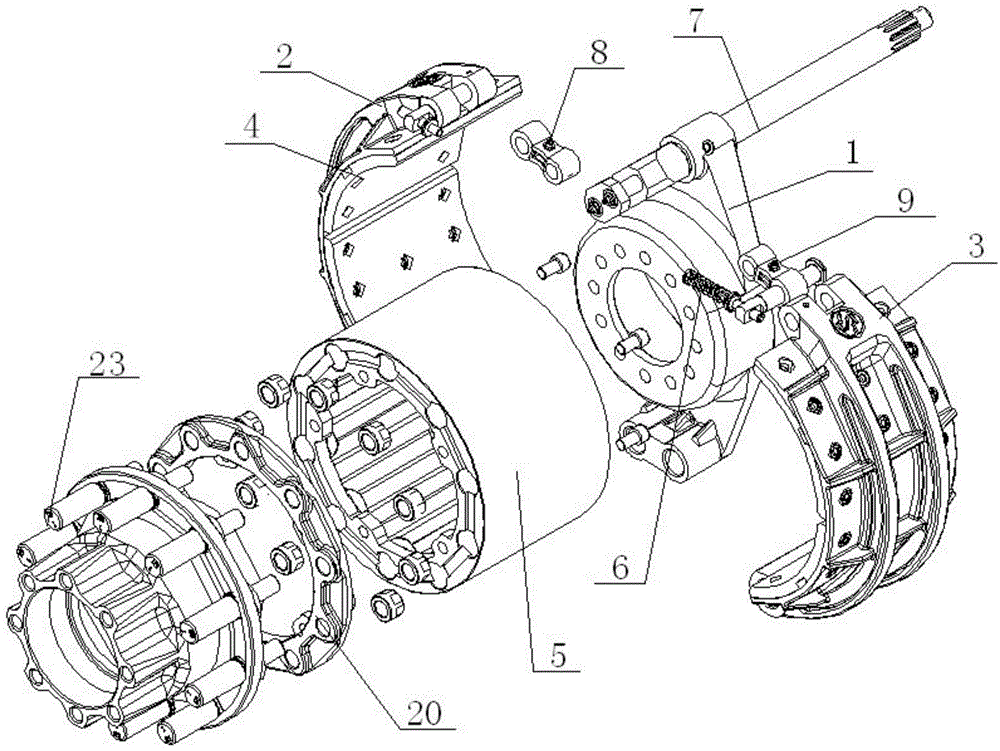

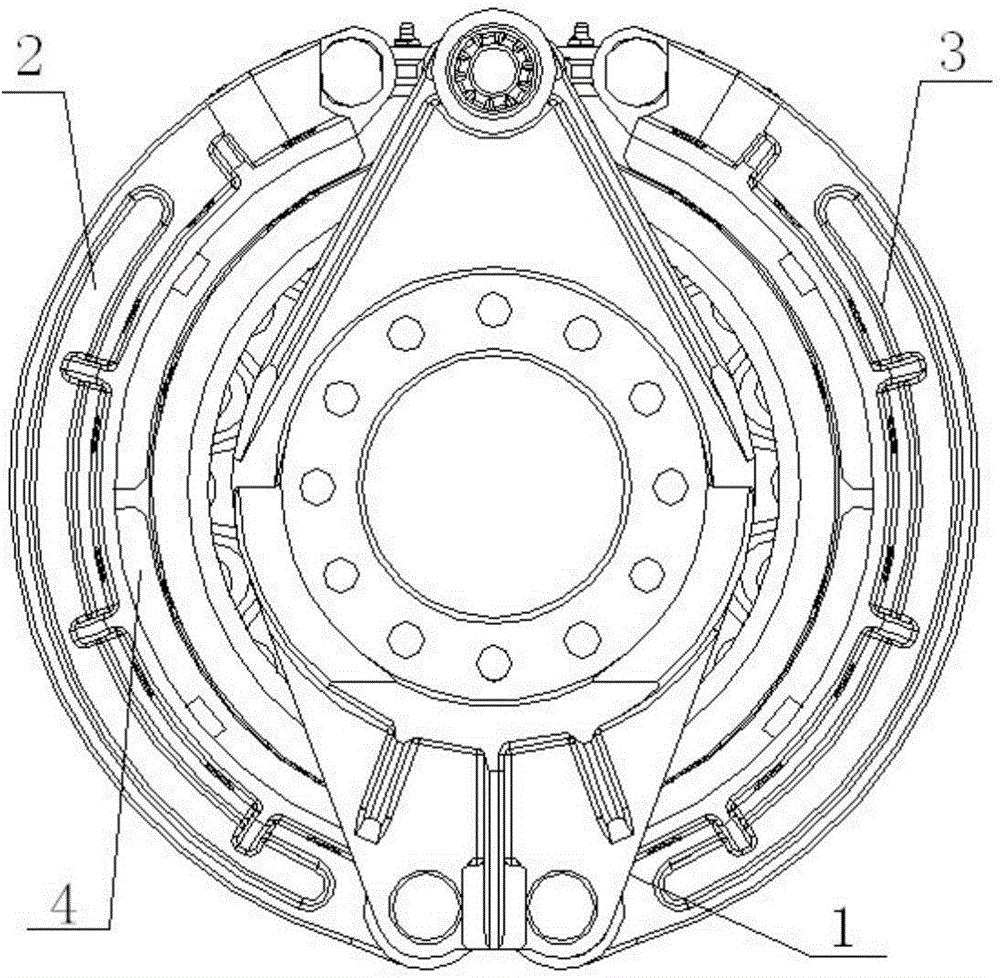

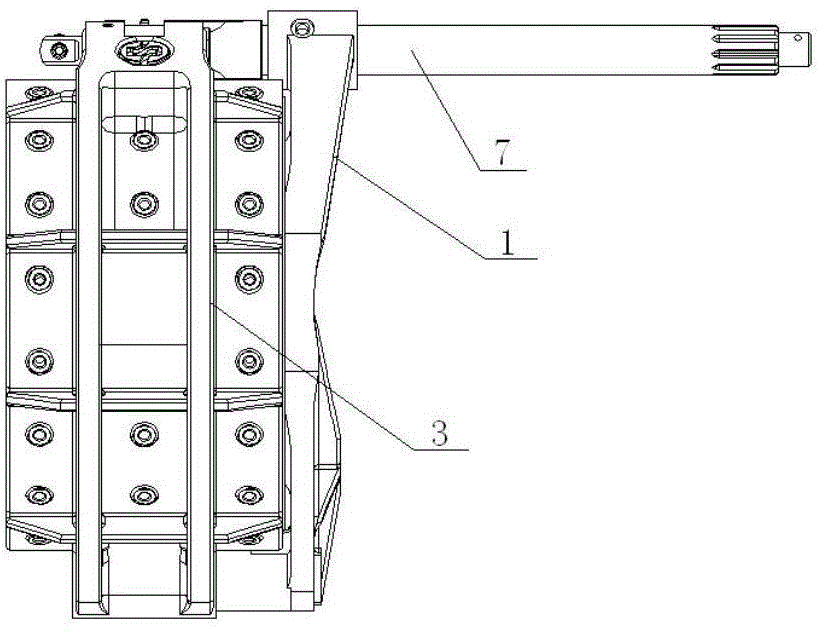

[0027] Such as Figure 1-3 As shown, a chain brake device for a truck includes a brake base plate 1, a brake shoe and a brake wheel 5. The brake base plate is a circular disc with a shaft hole at one end and a shaft hole at the other end. Two shoe shaft holes; one end of the brake shoe is hinged to the shoe shaft hole through the shoe shaft; the outer peripheral surface of the brake wheel is arranged with the inner peripheral surface of the brake shoe, and the other end of the brake shoe is connected with the linkage mechanism Configuration, linkage mechanism comprises linkage shaft 7, left connecting plate 8 and right connecting plate 9, and left and right connecting plate is symmetrically arranged on both sides of one end of linkage shaft, and the other end of left and right connecting plate links t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com