Coal mine waste moving processing device

A mobile treatment device and waste technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of high collection cost, high density, long incineration time, etc., to improve incineration efficiency, small size, and save processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

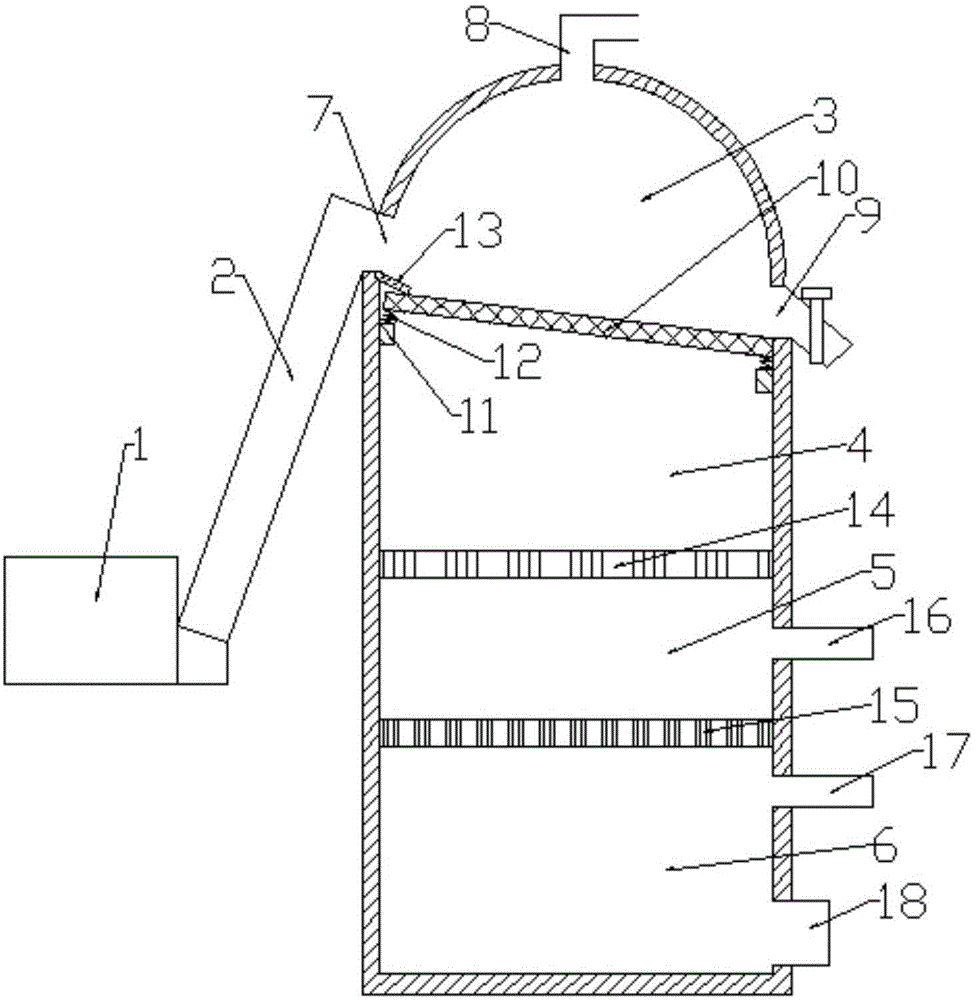

[0009] The specific embodiment of the present invention is described now in conjunction with accompanying drawing, as figure 1 Shown: coal mine waste mobile processing device, including a crushing device 1, a conveying device 2 and an incinerator, the crushing device 1 is connected to the feed port 7 of the incinerator through the conveying device 2, and the incinerator is from top to bottom The lower part includes the screening chamber 3, the first combustion chamber 4, the second combustion chamber 5 and the ash chamber 6 in sequence, the feed inlet 7 is on one side of the screening chamber 3, and the other side of the screening chamber 3 has a discharge port 9. There is a smoke exhaust pipe 8 on the top of the screening chamber 3, and there is a screen 10 installed obliquely between the screening chamber 3 and the first combustion chamber 4. The higher end of the screen 10 is at the inlet 7, and the lower end is at the outlet. Material opening 9; there is a coarse fire grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com