Cooling system of garbage power plant equipment

A technology for cooling systems and power plants, applied in lighting and heating equipment, refrigerators, refrigeration and liquefaction, etc., can solve the problems of complex pipelines, pipeline equipment damage, waste, etc., and achieve good cooling effect and high economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

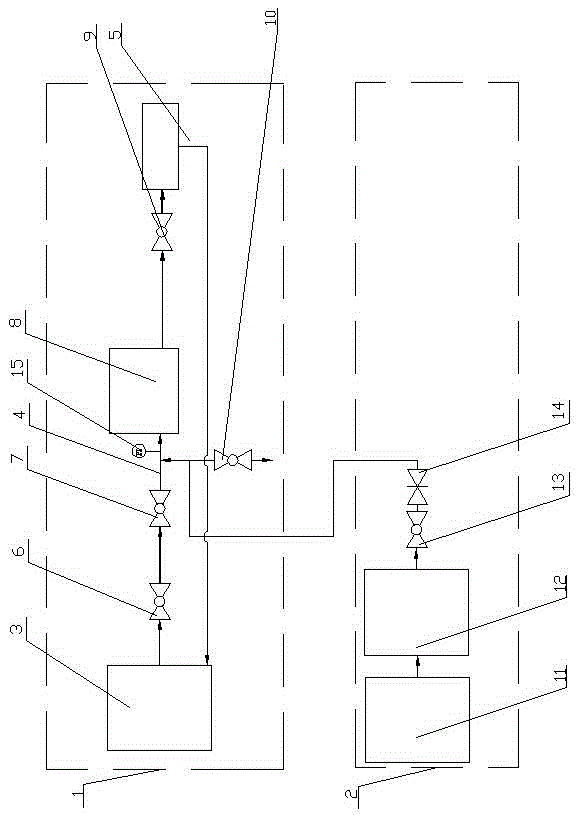

[0015] Such as figure 1 As shown, the present invention includes a circulating water cooling system 1 and a compressed air purging cooling system 2 .

[0016] The circulating water cooling system 1 includes a cooling water pool 3, an atomizing water pipe 4 for atomizing and cooling the equipment 8, and a circulating cooling water recovery pipe 5; the water outlet of the cooling water pool 3 is connected to a first ball valve 6, and the atomizing water pipe 4 is connected to There is a pressure gauge 15, the input end of the atomizing water pipe 4 is connected with the second ball valve 7, the output end of the first ball valve 6 is connected with the input end of the second ball valve 7, and the output end of the second ball valve 7 is also connected with a drain valve 10 ; The input end of the circulating cooling water recovery pipe 5 is used to recover the cooling atomized water, the output end of the circulating cooling water recovery pipe 5 is connected to the cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com