Image sequence and evaluation method and system for structured illumination microscopy

A pattern, space pattern technology, applied in the field of microscope system, can solve the problem of partial tilt, no provision, different height and reflectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

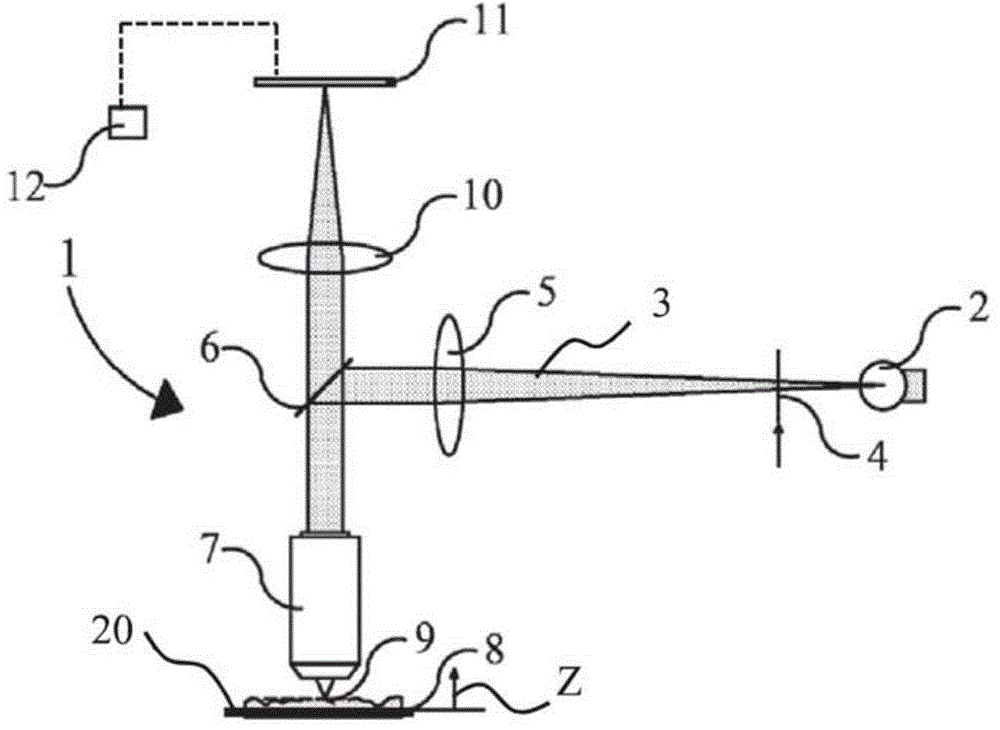

[0059] figure 1 An apparatus 1 for forming a three-dimensional (3D) height map of a specimen 8 is shown. The device 1 comprises a light source 2 constructed and arranged to generate a light beam 3 . In the path of the light beam 3 a spatial light modulator 4, a lens 5 and a beam splitter 6 are arranged. The device 1 also comprises an objective lens 7 adapted to receive and direct the beam of light 3, and a support 20 for carrying a specimen 8 whose upper surface 9 is to be determined with a height map. The device 1 is also equipped with a second lens 10, and a two-dimensional photodetector 11 (such as a camera) comprising an array of photodetector elements, each photodetector element being adapted to receive incident light of the light beam 3 The intensity is transformed into a signal. The signal is sent to a processing unit 12, preferably formed by a computer or computer system programmed to perform control of the device 1 and processing of signal data to provide said hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com