A New Braided Hose Pressure Testing System

A braided hose, pressure testing technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of long pressure time, high noise of the pressure test pump, large equipment volume, etc., and achieves simple structure and low noise. , the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

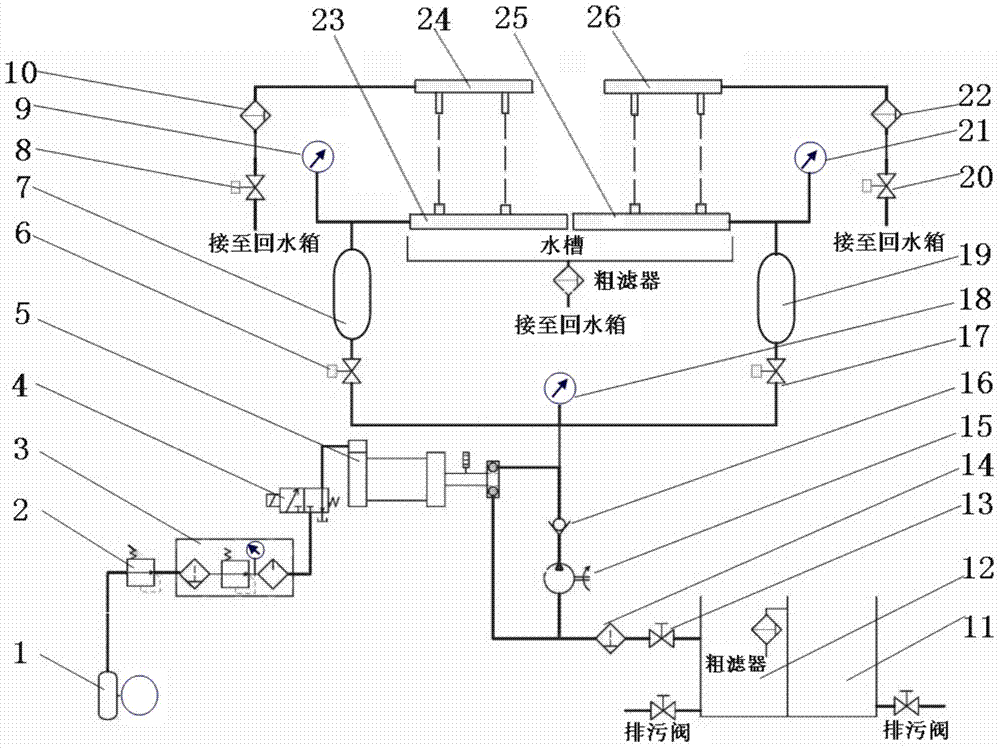

[0020] The new braided hose pressure test system is mainly composed of a water tank, a water pressure control system, an air pressure control system, and a test bench body;

[0021] The water pressure control system consists of a self-priming pump 15, a water supply tank 12, a return tank 11, a filter 14, a one-way valve 16, a brake hose loop solenoid valve 6, a brake hose loop regulator cylinder 7, and a brake hose Circuit pressure relief valve 8, total air hose circuit solenoid valve 17, total air hose circuit pressure regulator cylinder 19, total air hose circuit pressure relief valve 20 and other components; the water inlet of self-priming pump 15 is connected with the outlet of filter 14 The inlet of the filter 14 is connected with the water supply tank 12 through the water supply valve 13; the water outlet of the self-priming pump is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com