Tooth produced in a mold, and dental prosthesis

A tooth and mold technology, applied in the field of dental groups, can solve complex manual operations and other problems, and achieve the effect of improving retention characteristics and good retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

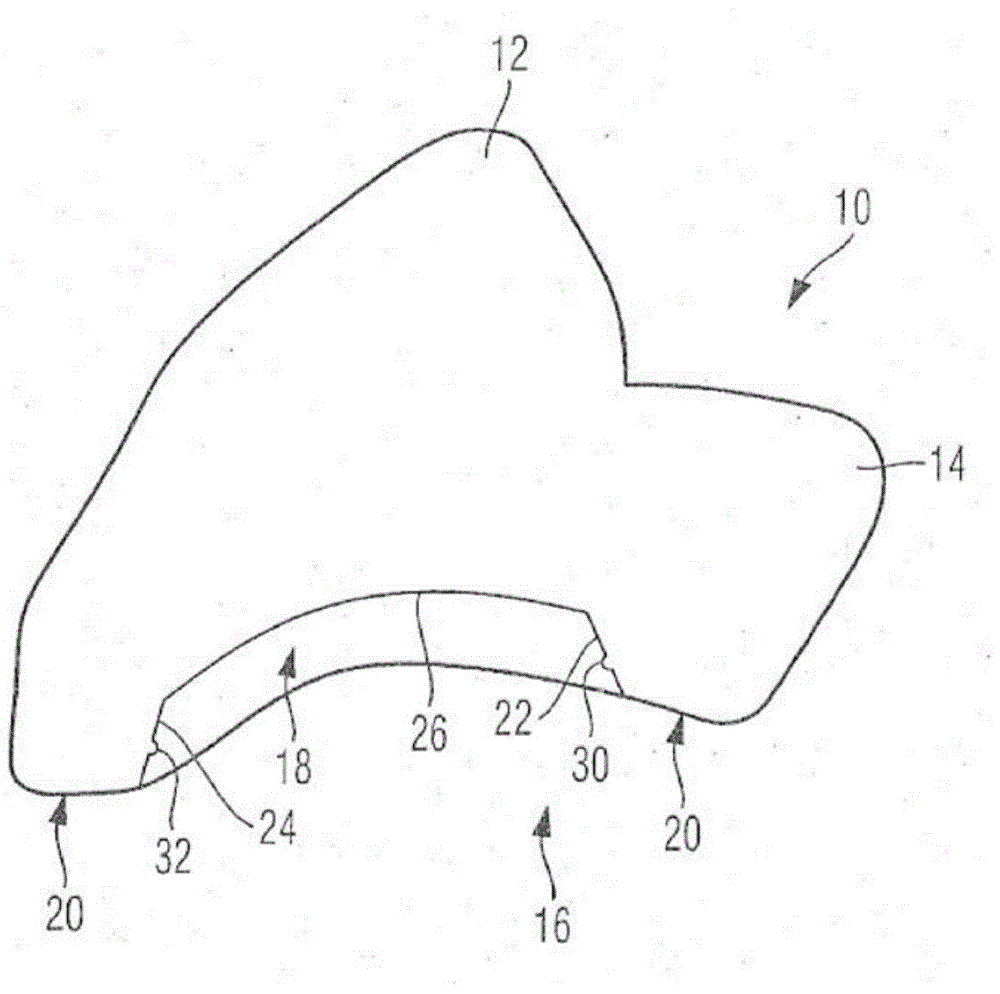

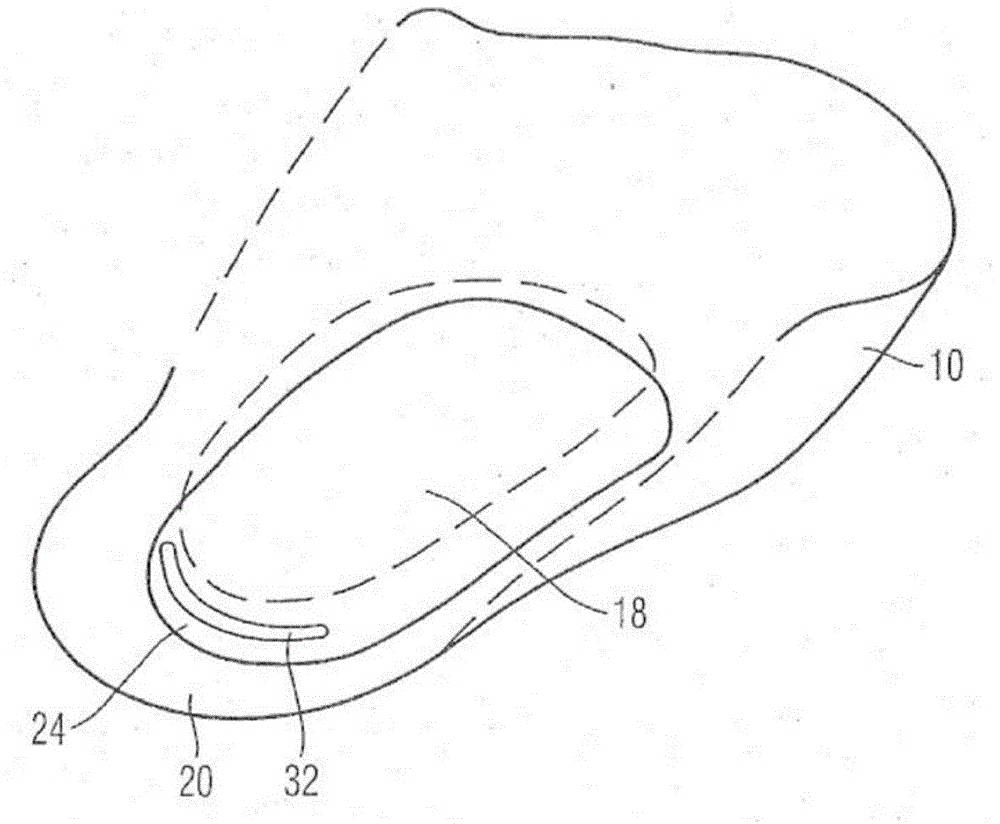

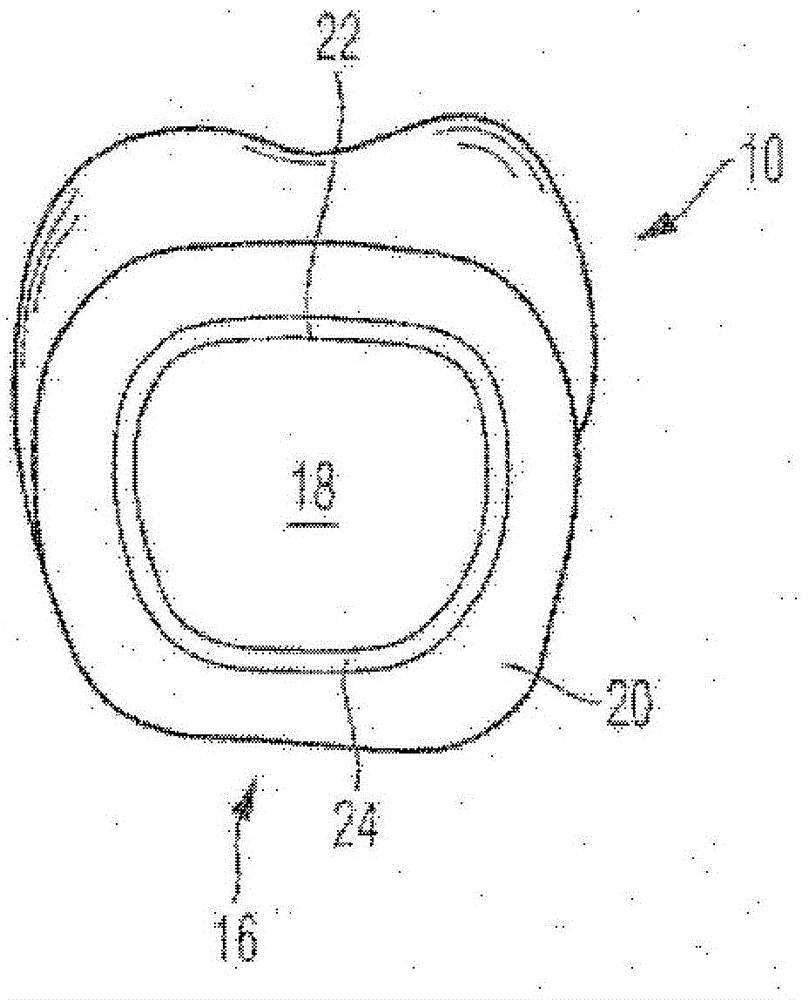

[0029] figure 1 The tooth 10 shown in has two protuberances 12 and 14 in a manner known per se. The base surface 16 extends on the underside of the tooth, thus on the side opposite the elevations 12 and 14 . The base area itself—that is to say even without taking into account the invention—is concave in the center and is therefore concave. A specially designed base cavity 18 according to the invention is cut into the base surface 16 as a bowl-shaped recess.

[0030] A base edge surface 20 substantially surrounding the base cavity 18 and having essentially the same width extends laterally of the base cavity. The cavity side wall 22 or 24 adjoins the base edge surface 20 . The sidewall of the cavity is in accordance with figure 1 In the illustration on the left side, that is, the cavity side wall 24 extends at an angle of about 75° relative to the base edge side 20, while on the right side, that is, the cavity side wall 22 extends at an angle relative to the The base edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com