Irradiation pretreatment process for producing dry fruits and vegetalbe

A technology of pretreatment and drying of fruits and vegetables, which is applied in food preparation, food preservation, food science, etc., can solve the problems of poor rehydration, uneven water loss, and destruction of nutritional components of dried products, achieving small physical and chemical denaturation and maintaining original Characteristic, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] The present invention will be described in detail below in conjunction with specific examples. Example 1: Take potatoes as an example

[0018] Pick potatoes, remove damaged and diseased ones, make sure they are similar in size, clean them, drain them, seal them with plastic film, and then irradiate them. The irradiation dose is 4KGy evenly cut. The total irradiation time is 2 hours. After 1 hour of irradiation, the carton is rotated 180°, and then irradiated for 1 hour. After irradiating, all sheets were 4mm thick, but they were dried by hot air, the temperature of the hot air was 65°C, and the speed of the hot air was 1m / s. In this way, dried potatoes with the best appearance quality can be obtained.

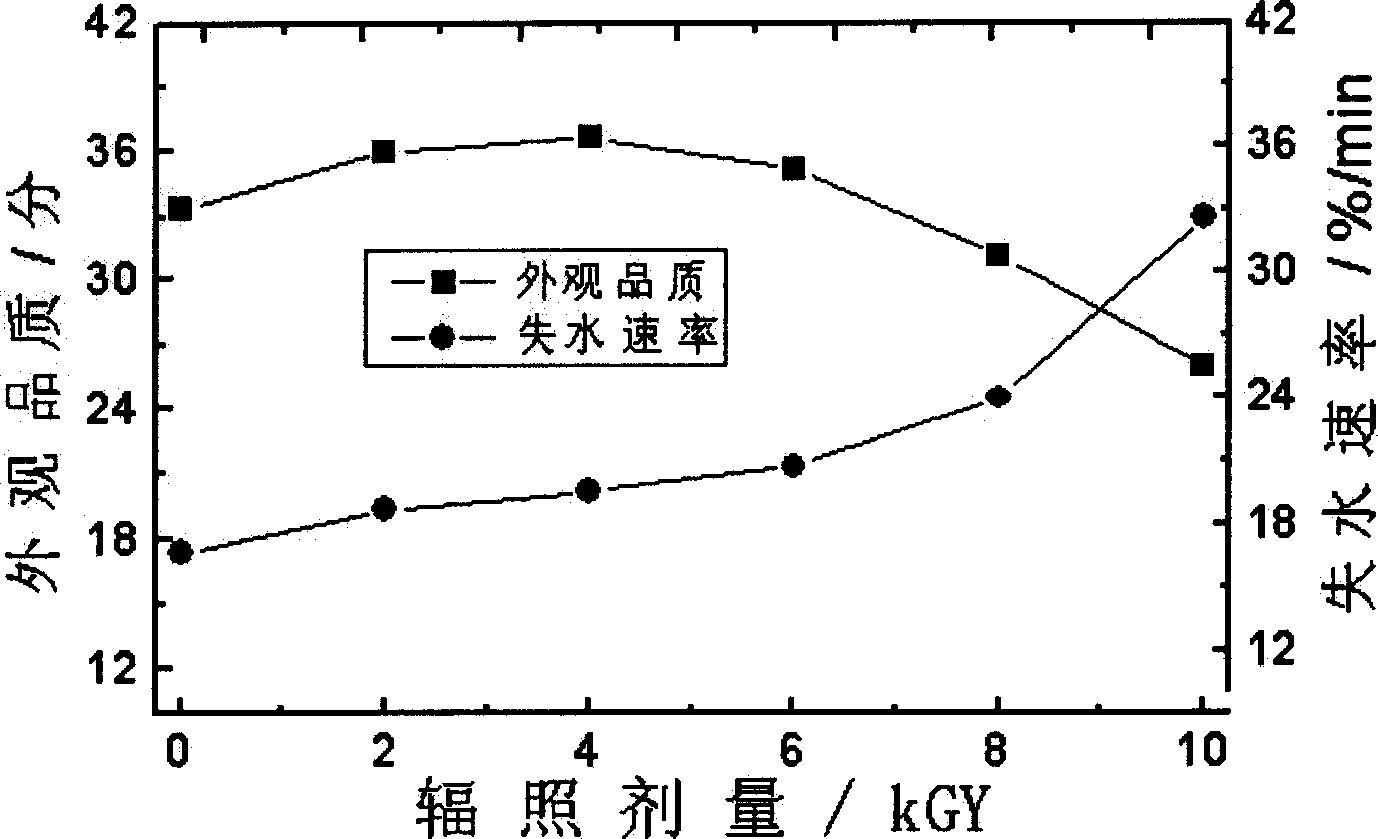

[0019] See the influence of different radiation doses on the drying rate and the appearance quality of dried products figure 1 (The appearance quality is quantified by color and surface shape, the best score is 40).

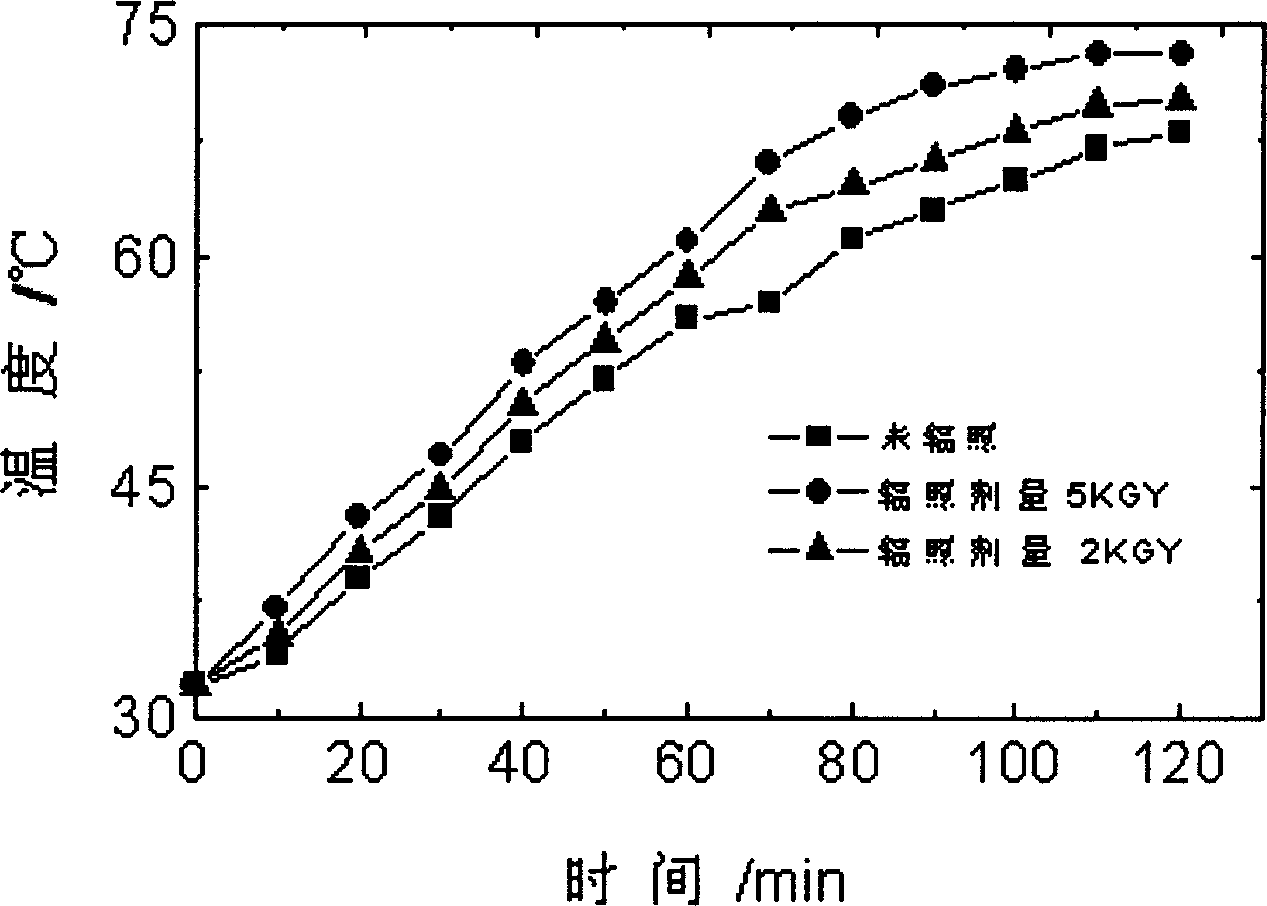

[0020] See the temperature change of potatoes during the...

example 2

[0021] See Table 1 for the optimized parameter combinations for potato chips drying. Tests have shown that for the appearance quality of dried potato chips, it is better to take the irradiation dose as the medium, the hot air temperature as the medium, and the slice thickness as the medium (4KGy, 65℃, 4mm); for the drying rate, the irradiation dose is taken as It is better when the hot air temperature is high and the slice thickness is thin (10KGy, 70℃, 2.6mm); for the rehydration ratio of dry products, the irradiation dose is low, the hot air temperature is high, and the slice thickness is thin (2KGy). , 70℃, 2.6mm). Example 2: Take Apple as an example

[0022] The apples are selected, the damaged and diseased ones are removed, and the sizes are the same. They are cleaned, drained and sealed with plastic film, and then irradiated. The irradiation dose is 3KGy. The total irradiation time is 2 hours. After 1 hour of irradiation, the carton is rotated 180°, and then irradiated for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com