Dynamo-electrical machine with segmented stator structure and/or rotor structure

An electric power and machine technology, applied in the field of large electric power machines, can solve the problems of tedious work and cost, achieve the effect of simple bolt connection and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

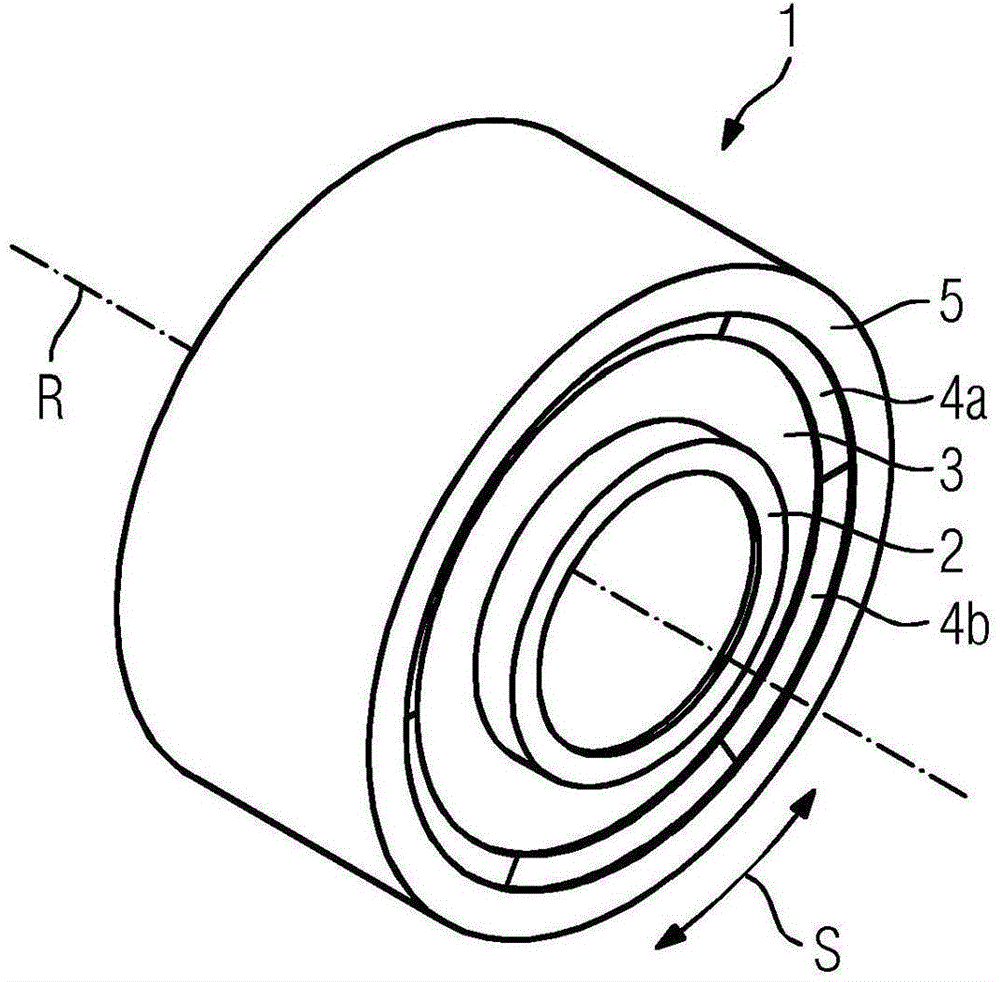

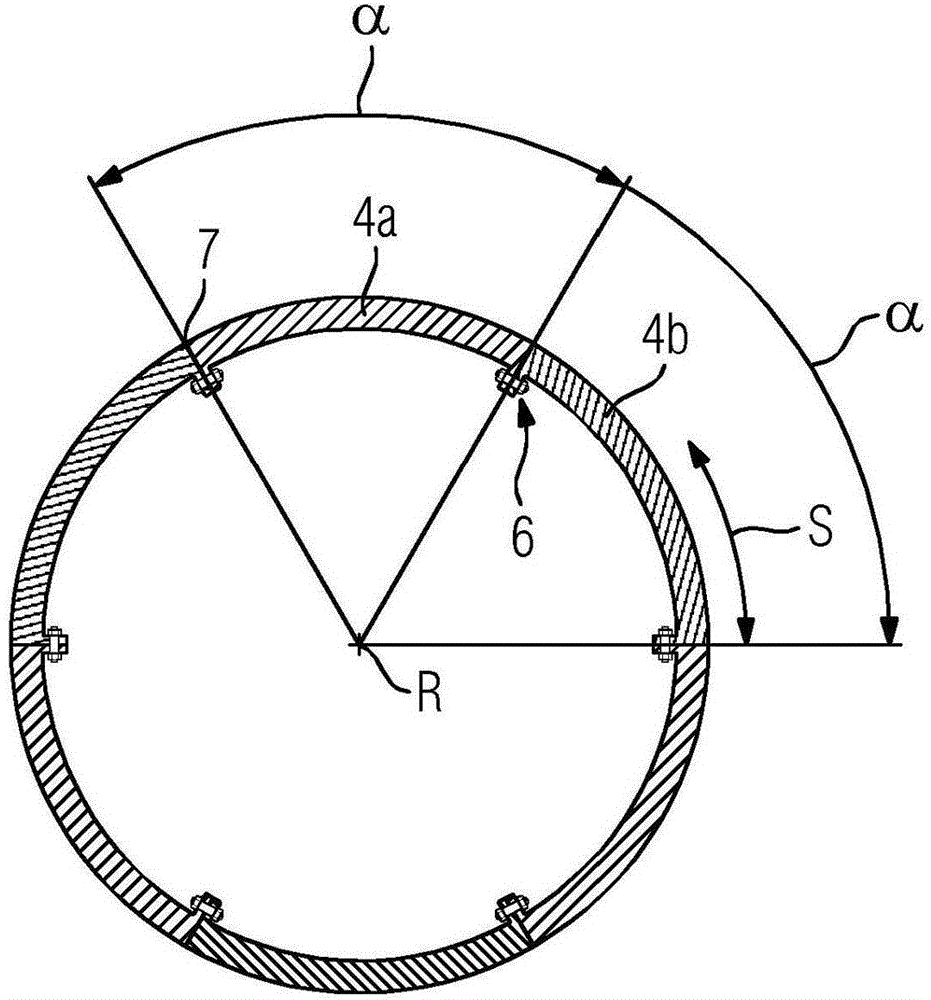

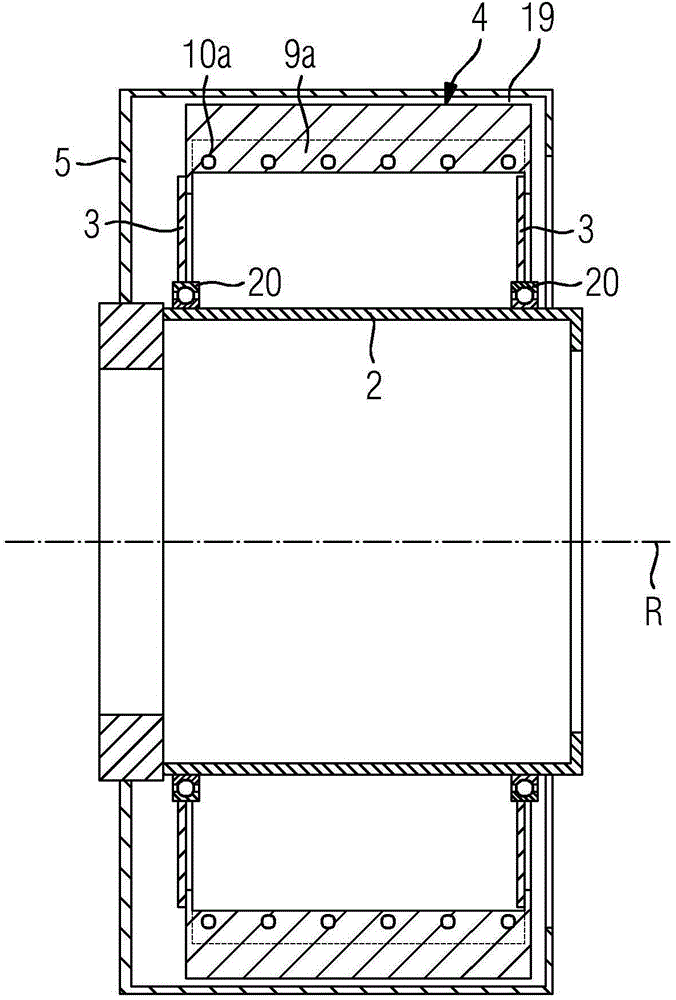

[0016] figure 1 The electrodynamic machine 1 according to the invention is shown in a perspective schematic illustration. The electrodynamic machine 1 has a rotor 5 arranged rotatably about an axis of rotation R, which rotates about the axis of rotation R in a direction of rotation S during operation of the electrodynamic machine. Furthermore, the electrodynamic machine 1 has a stationary stator 4 which, within the scope of the present exemplary embodiment, is positioned via a bearing on the shaft 2 by means of a carrier. The stator 4 has segments 4 a , 4 b arranged one behind the other in the direction of rotation S of the rotor 5 , of which only two segments have been designated for the sake of clarity. The segments are arranged in a ring here. The carrier device 3 connects the shaft 2 to these sections of the stator 4 via bearings. Within the framework of the present exemplary embodiment, the electrodynamic machine 1 is designed as a so-called outer rotor, ie the rotor 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com