Selenium sulfide ultrafine powder and preparing method thereof

A technology of selenium disulfide and ultrafine powder is applied in cosmetic preparations, sulfur/selenium/tellurium active ingredients, cosmetics, etc. The effect of large surface charge, shortened production time, and simplified production process

Active Publication Date: 2016-04-06

张志昂

View PDF2 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

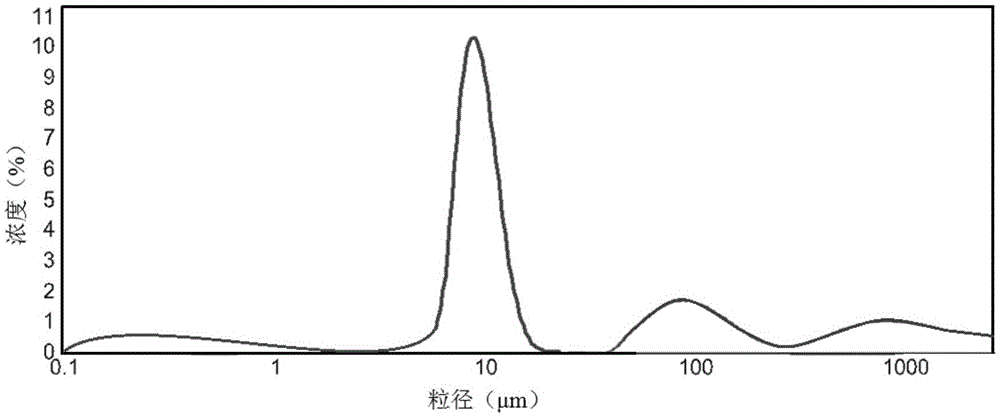

[0005] The invention solves the quality problems of large selenium disulfide particles, uneven dispersion and instability in the preparation of selenium disulfide ultrafine powder as a lotion by medium ball milling micronization, shortens the production time at the same time, and provides ultra-fine selenium disulfide Micropowder and its preparation method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

[0026] Embodiment 1: In this embodiment, the particle size of the ultrafine powder of selenium disulfide is 1 μm.

specific Embodiment approach 2

[0027] Embodiment 2: In this embodiment, the particle size of the ultrafine powder of selenium disulfide is 30 μm.

specific Embodiment approach 3

[0028] Embodiment 3: In this embodiment, the particle size of the ultrafine powder of selenium disulfide is 50 μm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a selenium sulfide ultrafine powder and a preparing method thereof, and belongs to the field of washing products. The selenium sulfide ultrafine powder and the preparing method solve the problem that the production time of selenium sulfide ultrafine powder which is prepared through medium ball milling micronization and serves as a lotion is long, and the quality problems that selenium sulfide is large in particle, uneven in dispersion and instable. The particle size of the selenium sulfide ultrafine powder is 1-50 microns. The method includes the following steps that 1, dry selenium sulfide powder, purified water, medicine-level titanium dioxide and medicine-level glycerin are mixed to be even, and then citric acid is added to adjust the pH value to range from 3.5 to 4.5; 2, the mixture is arranged in a grinding-type ultrafine grinder to be ground and smashed, and the selenium sulfide ultrafine powder is obtained. The selenium sulfide ultrafine powder can be applied to daily chemical products such as lotions, liquid shampoo and hair conditioners.

Description

technical field [0001] The invention belongs to the field of washing products; in particular, it relates to an ultrafine powder of selenium disulfide and a preparation method thereof. Background technique [0002] Selenium disulfide is bright orange to reddish brown powder; with a faint hydrogen sulfide smell, insoluble in water, slightly soluble in chloroform, very slightly soluble in ether, basically insoluble in other organic solvents. Under sunlight, high temperature or alkaline conditions, it is easy to oxidize, deactivate and turn black; the product must be protected from light and stored in a cool, airtight container. [0003] Selenium sulfide is used to remove dandruff, seborrhea, scalp seborrheic dermatitis, tinea versicolor and so on. It is often used for external use, with 1% or 2.5% lotion applied to the scalp, 1-2 times a week to once every 4 weeks as needed. [0004] Micronization technology is a new technology derived from the 1970s to adapt to the developme...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61K33/04A61K9/14A61K47/02A61K47/10A61P17/08A61P31/10A61P17/00A61K8/23A61K8/29A61K8/34A61Q5/02A61Q5/12

CPCA61K8/23A61K8/29A61K8/345A61K9/0014A61K9/143A61K9/145A61K33/04A61K2800/412A61Q5/02A61Q5/12

Inventor 张志昂

Owner 张志昂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com