High-uniformity foam asphalt generating device

A technology of foamed asphalt and generating device, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt and the petroleum industry, etc. It can solve the problems of easy blockage of water nozzles, inability to sample in real time, poor foaming uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0019] Structure description:

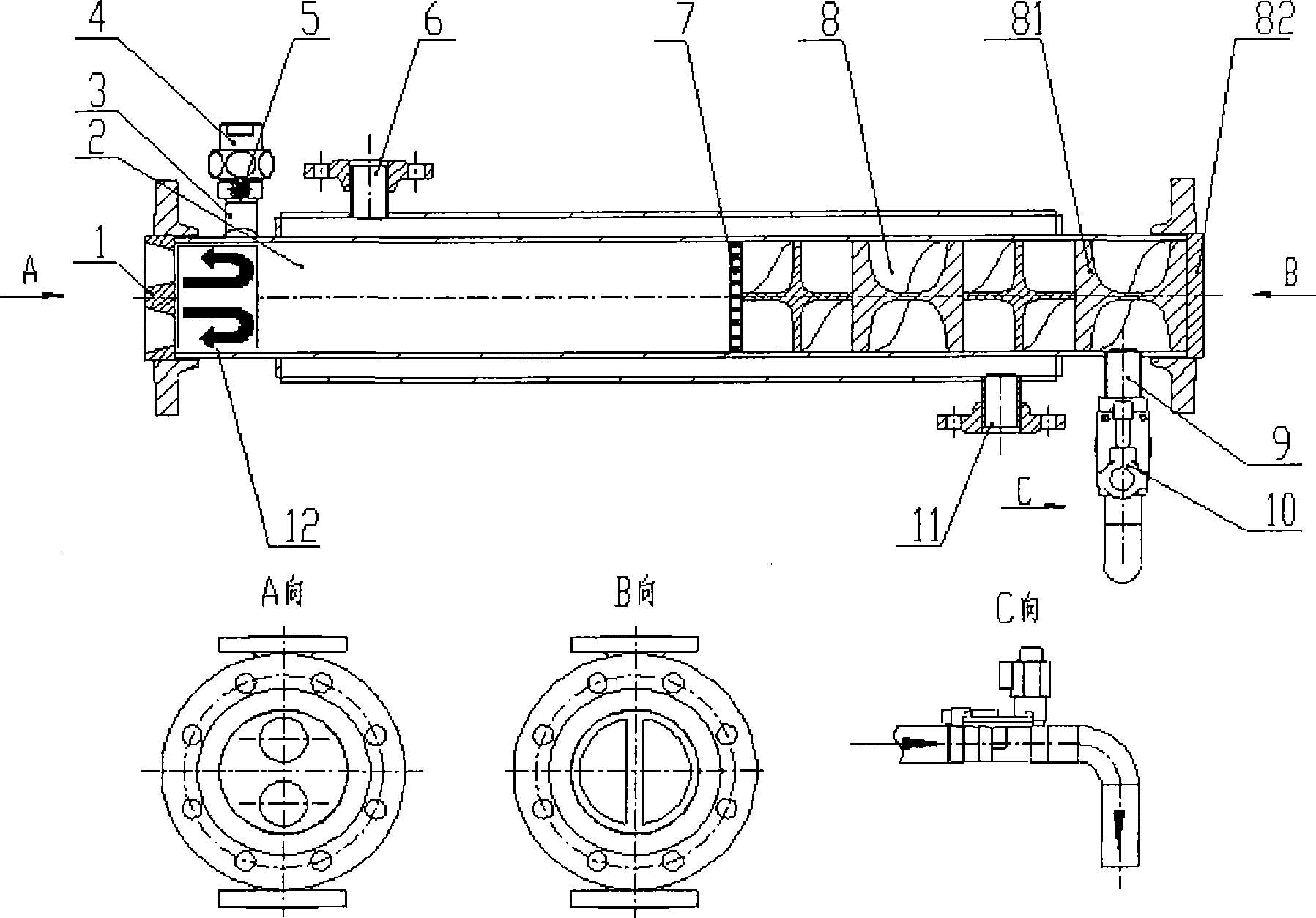

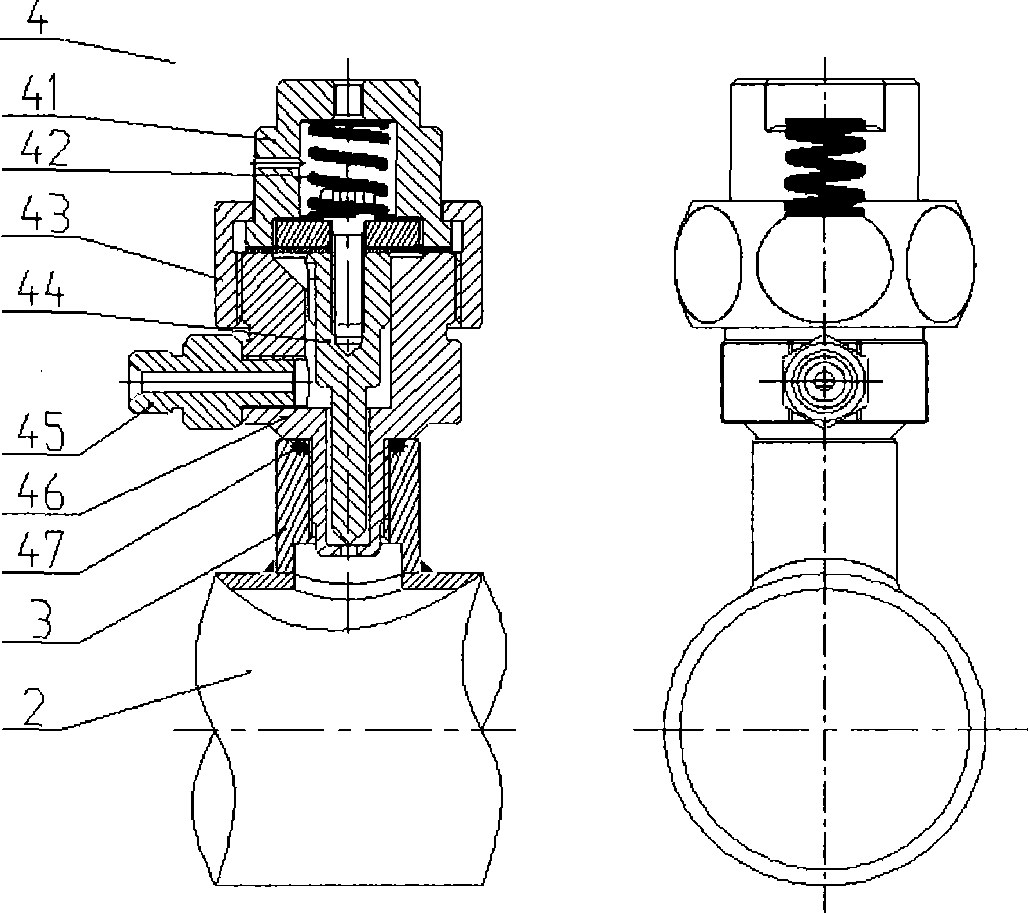

[0020] refer to figure 1 As shown, a high-uniformity foamed asphalt generating device includes asphalt deflector 1, asphalt foaming chamber 2, nozzle joint 3, anti-backflow nozzle 4, tee joint 5, heat transfer oil outlet 6, and asphalt foam homogenizing plate 7. Spiral mixing mechanism 8, spiral blade 81, mounting plate 82, foamed asphalt sampling pipe 9, sampling solenoid valve 10, heat transfer oil inlet 11, vortex area 12, further, the asphalt deflector 1 is circular, and its thickness is greater than 20mm, its diameter is the same as the inner diameter of the asphalt pipe, and the cross-section of the 2-3 diversion holes on it can be circular, elliptical and square, and the diversion holes can be columnar or frustum-shaped through holes. The orifice causes the asphalt to generate a negative pressure area at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com