Multi-shaft straw crusher

A crusher and straw technology, applied in agricultural machinery and tools, cutting equipment, applications, etc., can solve the problems of large power input and non-rotating shaft, and achieve the effects of small crushed particles, improved crushing efficiency, and easy operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

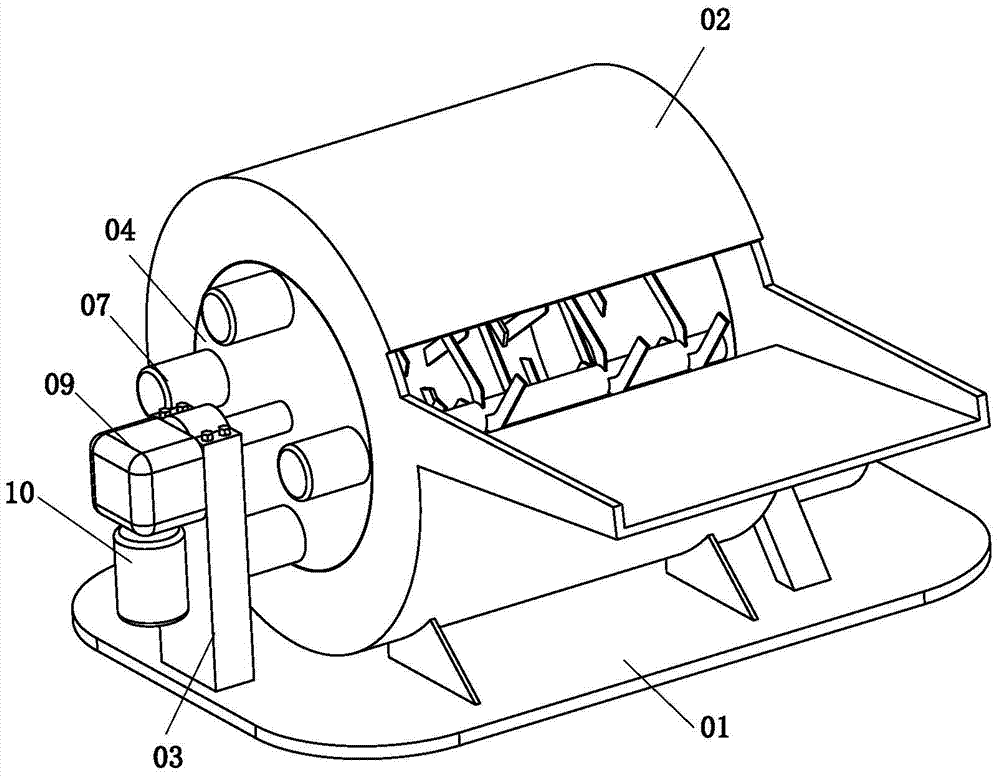

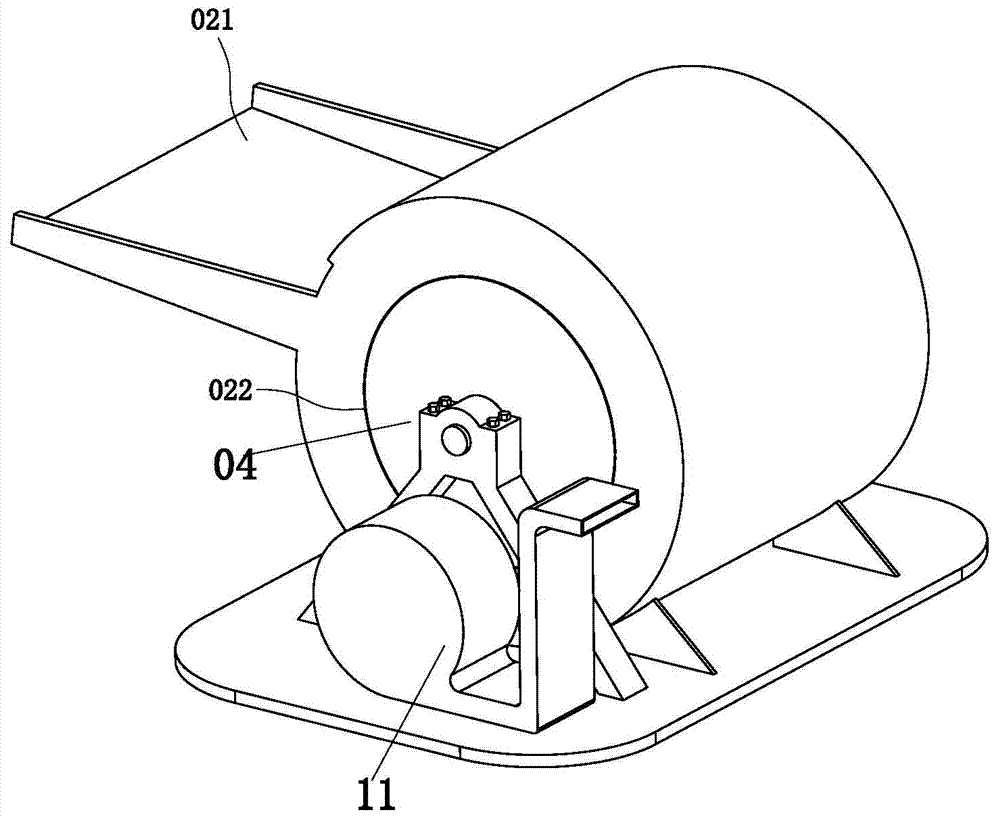

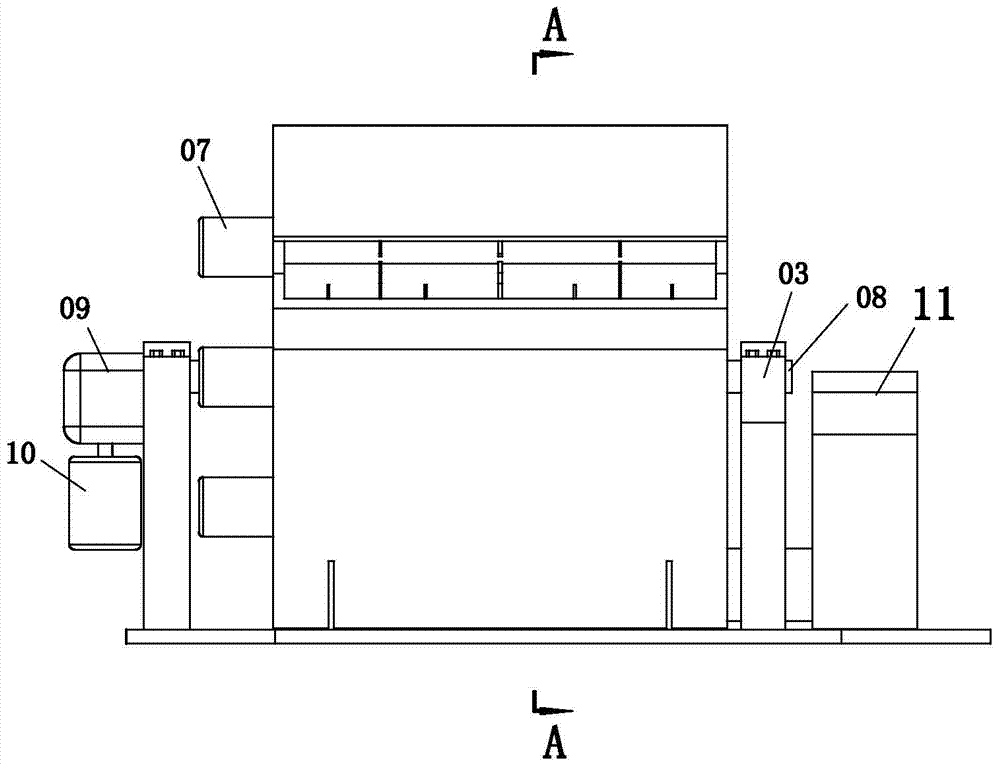

[0019] Such as Figure 1 to Figure 5 As shown, a multi-shaft straw crusher according to the present invention includes a bottom plate 01, a housing 02, two brackets 03, two connecting discs 04, four crushing shafts 05, four groups of crushing knives 06, four A crushing motor 07, two rotating shafts 08, a reducer 09, a driving motor 10 and a fan 11, the casing 02 is fixed above the bottom plate 01, and the straw is crushed in the casing 02, and the two brackets 03 They are respectively located on both sides of the shell 02, and the bracket 03 plays a supporting role. The front end of the shell 02 is provided with a feed port 021, and the straw enters and crushes through the feed port 021. The two sides of the shell 02 are provided with through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com