Conveying mechanism of metal wire cut-off machine

A technology of cutting machine and metal wire, applied in the field of transport mechanism of copper wire cutting machine, can solve the problem of inability to transport large and small load-bearing containers, etc., and achieve the effect of improving firmness and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

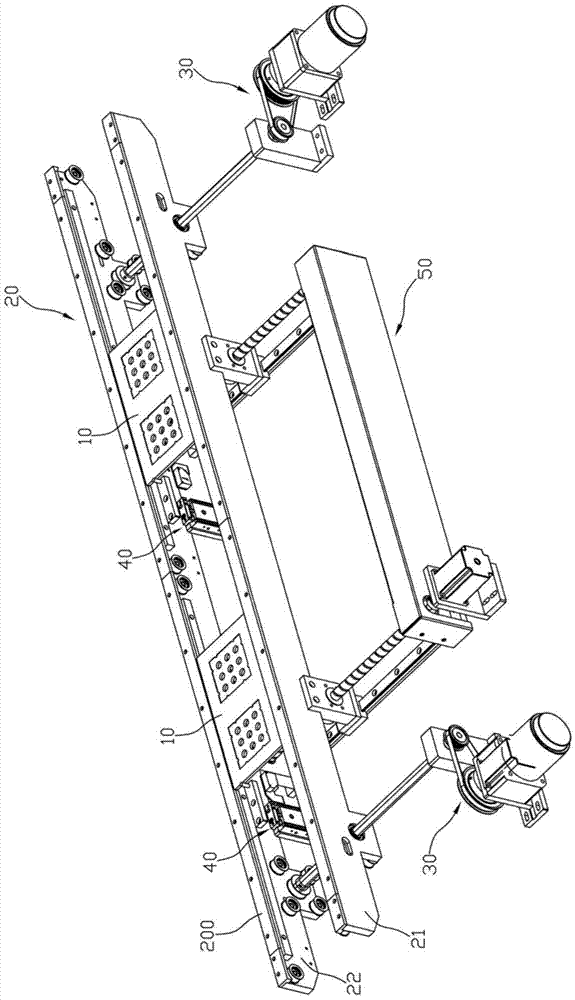

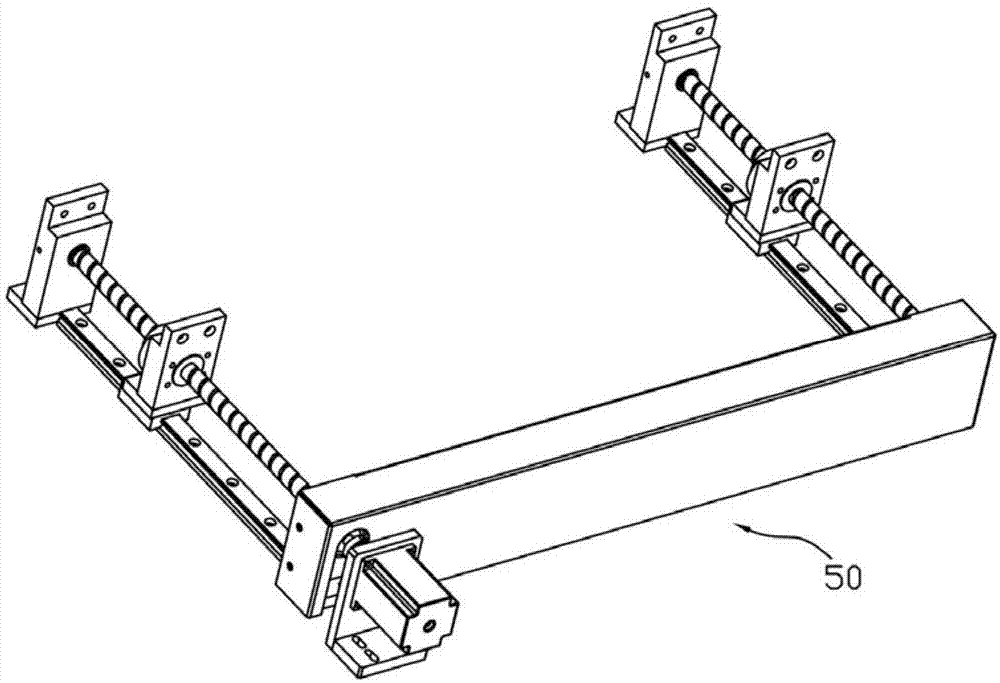

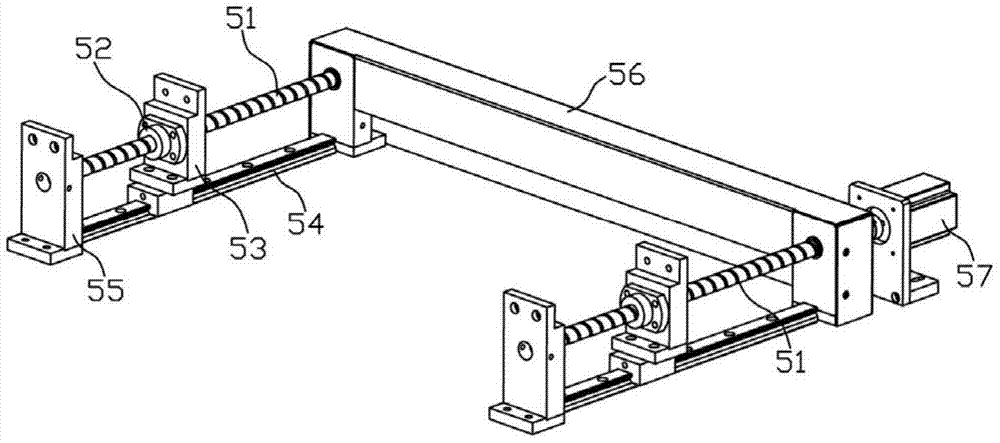

[0025] Such as figure 1 As shown, a transport mechanism of a wire cutting machine includes a load plate 10 , a transport track 20 , a drive system 30 , a positioning device 40 , and a screw mechanism 50 .

[0026] Such as Figure 7 As shown, a groove 100 is defined on the carrier board 10 , a plurality of through holes 101 are defined in the groove 100 , and a plurality of protrusions 102 are formed on the inner wall of the groove 100 .

[0027] Such as figure 1 As shown, the transport track 20 includes a first support plate 21 and a second support plate 22, a guide bar 200 installed on the top of the first support plate 21 and the second support plate 22, a guide strip 200 installed on the top of the first support plate 21 and the second support plate The conveyor belt inside the support plate 22 and below the guide strips 200 , the carrier plate 10 is placed on the conveyor belt and between the two guide strips 200 .

[0028] Such as Figure 5 As shown, the drive system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com