Automatic punching device for pouring riser of automobile steering gear motor shell

A technology for automobile steering gear and motor casing, applied in the field of punching devices, can solve the problems of low degree of automation, rising manufacturing cost, difficult management, etc., to meet processing requirements and clamping requirements, reduce impact and labor intensity, and ensure product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

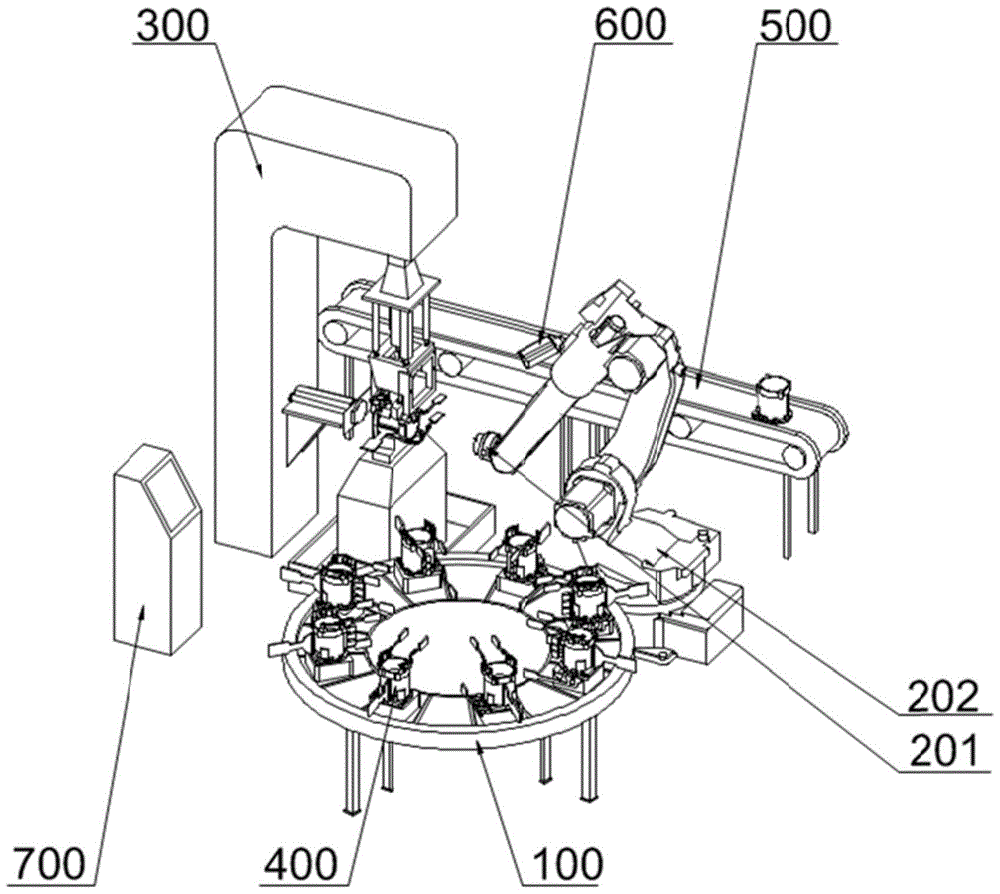

[0035] see figure 1 , the present invention comprises processing module 300, loading module 100, unloading module and manipulator 202, and loading module 100 and unloading module are arranged on the both sides of manipulator 202 and processing module 300 respectively, and CCD camera 600 is arranged on manipulator 202 and conveyor belt 500, the CCD camera 600 is installed on the ground through a bracket; the automobile steering gear motor casing 400 is conveyed in the loading module 100, is grabbed by the manipulator 202 and placed in the processing module 300 for punching, and then the image is collected by the CCD camera 600 and placed in the unloading module.

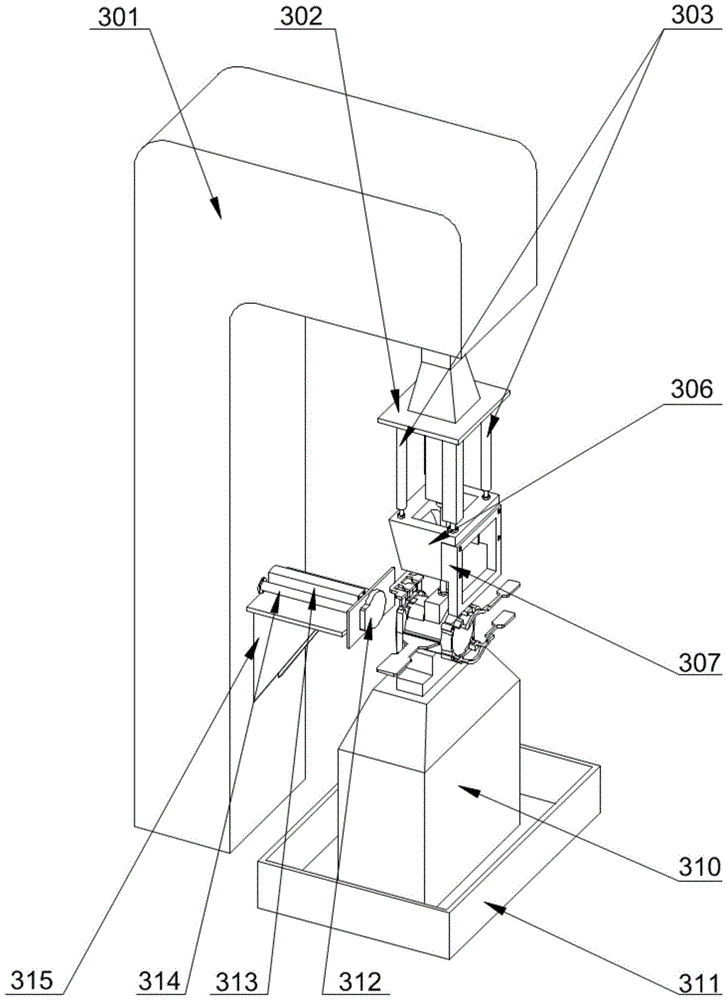

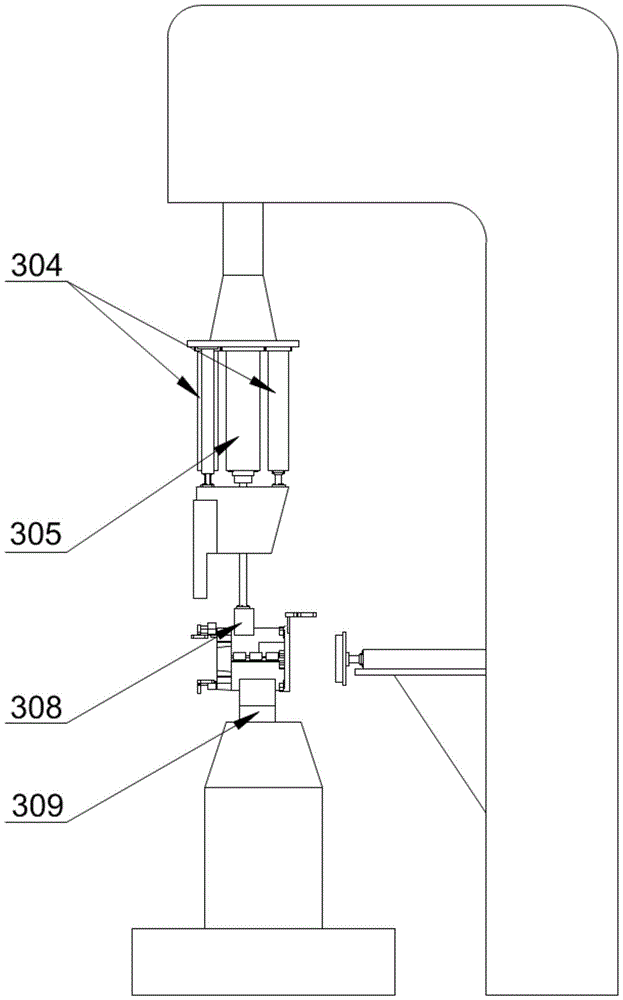

[0036] see figure 2 and image 3 , the processing module is used to automatically clamp the automobile steering gear motor housing 400 and remove the pouring riser 401 . The processing module 300 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com