Gel method preparation process for SiC/Al composite powder

A technology of composite powder and preparation process, which is applied in the field of composite powder preparation, can solve the problems of limited use of SiC/Al composite materials, insufficient two-phase dispersion, and low product yield, so as to improve performance and product quality. The qualified rate of appearance, wide range of use, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

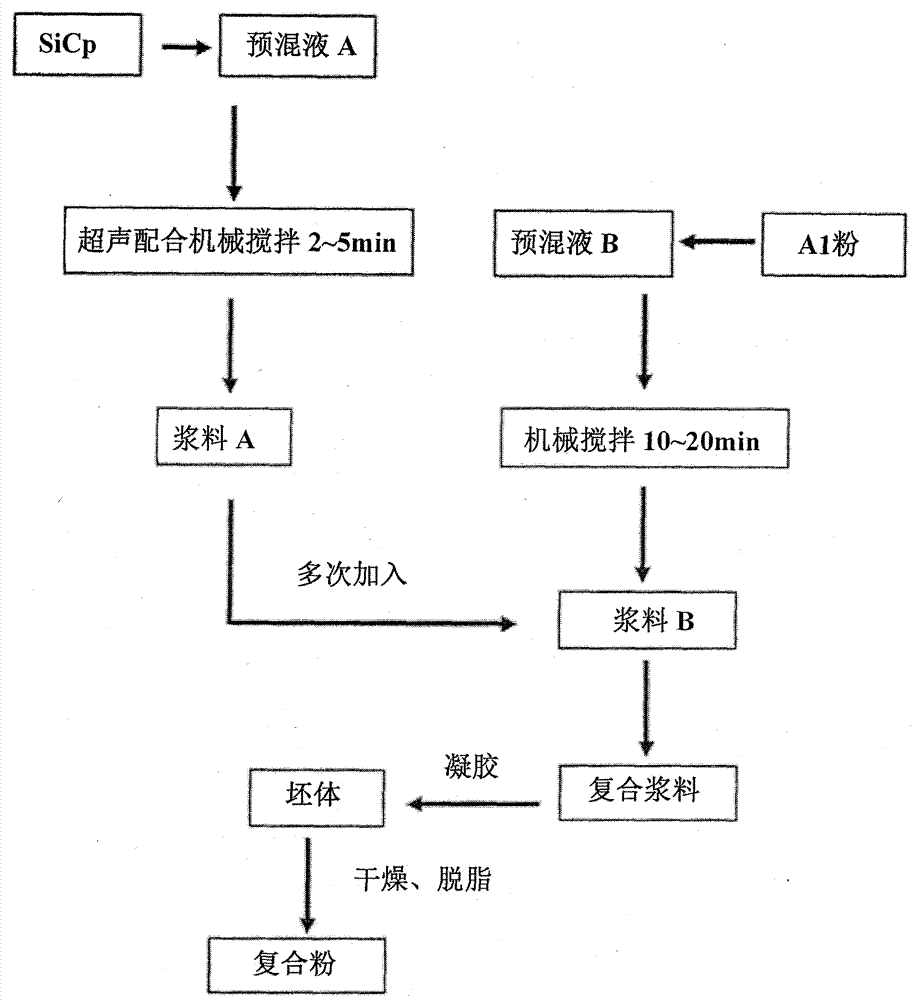

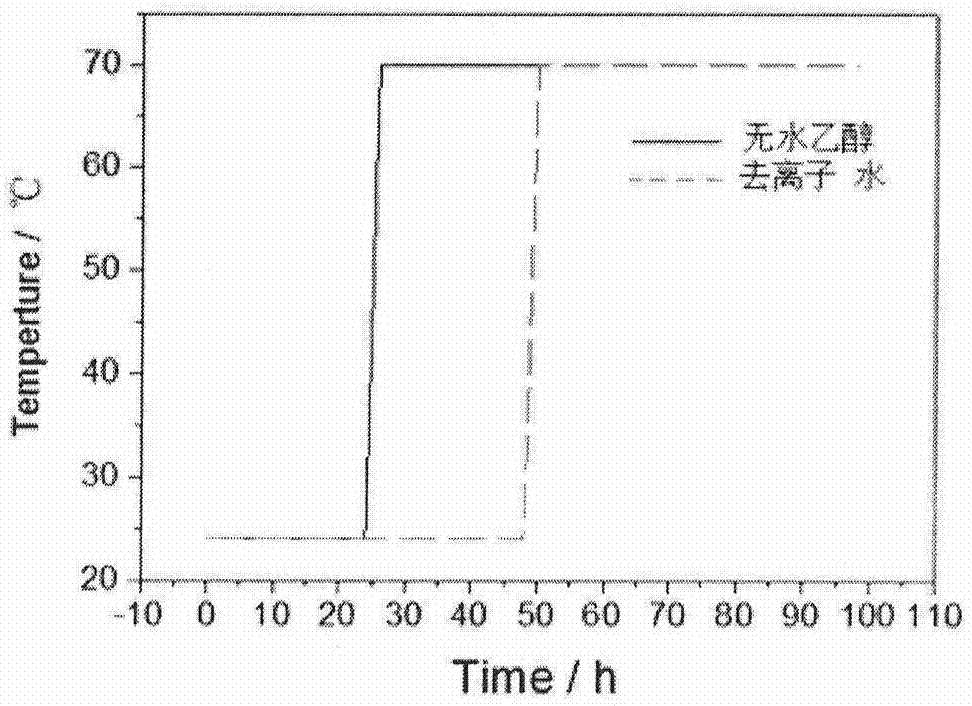

[0037] According to the slurry A and slurry B made of different premix components, add a small amount of slurry A to slurry B several times and mix for 20-30min. At this time, the solid phase in the slurry basically tends to be stable and uniformly dispersed; Add a catalytic-initiating system to the slurry to promote the solidification of the colloidal components in the slurry. This process does not exceed 30s; according to image 3 During the process, the green body is dried at room temperature / 48h, 70°C / 24h, and the dried green body is Figure 4 Degreasing treatment at 100°C-450°C is carried out in the equipment to obtain a composite powder with uniform composition. Figure 5 (a) and (b) are scanning electron micrographs of degreased composite powders with SiC volume fractions of 17% and 25%, respectively. The irregular shapes and sharp corners in the figure are SiC. Observing the distribution of SiC in the composite powder, it can be seen that SiC in the composite powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com