Multistage equal deformation elastic positioning and clamping device

An elastic positioning and clamping technology, which is applied in positioning devices, clamping devices, clamping, etc., can solve the problem that the processed parts cannot be accurately positioned and clamped, the precision of the parts is out of tolerance, and the mandrel cannot be completely fitted, etc. problem, to achieve the effect of simple structure, high positioning and clamping precision, and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

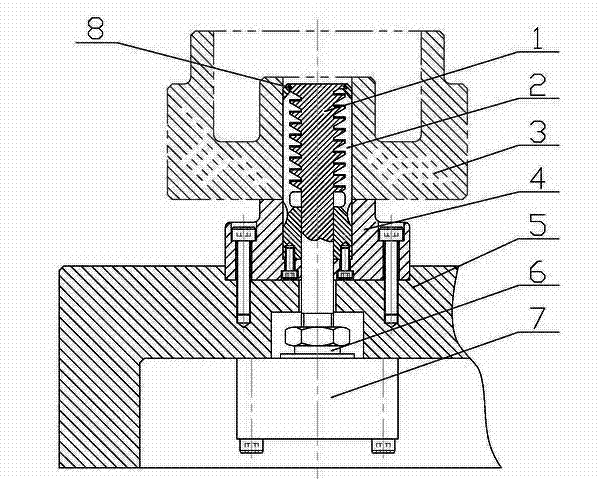

[0016] Such as figure 1 As shown, the multi-stage toothed elastic jacket 2 is fixed on the positioning base 4, the multi-stage toothed tie rod mandrel 1 is arranged in the inner hole of the multi-stage toothed elastic jacket 2, and the multi-stage toothed tie rod core The tooth structure of the shaft 1 and the multi-stage toothed elastic jacket 2 is composed of a horizontal plane symmetrically distributed along its center line and an inclined plane 10-30 degrees from the horizontal plane. The top of the multi-stage toothed elastic jacket 2 has Dustproof ring 8; positioning base 4 is installed on clamp body 5; piston rod 6 of magnetic induction type oil cylinder 7 is connected with external thread of multi-stage toothed tie rod mandrel 1 through its own internal thread, and magnetic induction type oil cylinder 7 is installed In the clamp body 5.

[0017] Working principle of the present invention:

[0018] 1. When loosened, the piston rod 6 of the magnetic induction oil cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com