Locally induced attached rotary ultrasonic head based on machine tool

A technology of ultrasonic head and machine tool, which is applied in the direction of metal processing machinery parts, clamping, support, etc. It can solve the problems of low energy transfer efficiency, troublesome tool change, and oversized size, so as to reduce the possibility of interference and meet the requirements of high-power processing. , The effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only to illustrate the present invention, and are not intended to limit the present invention.

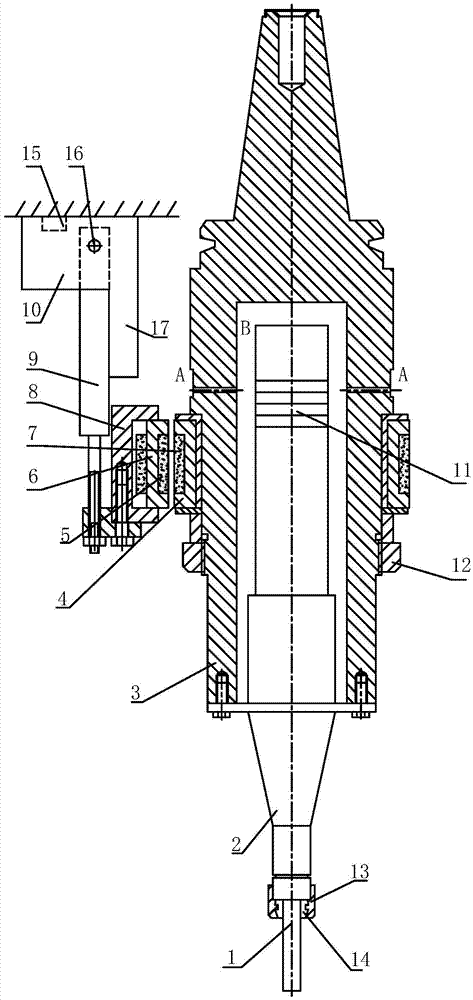

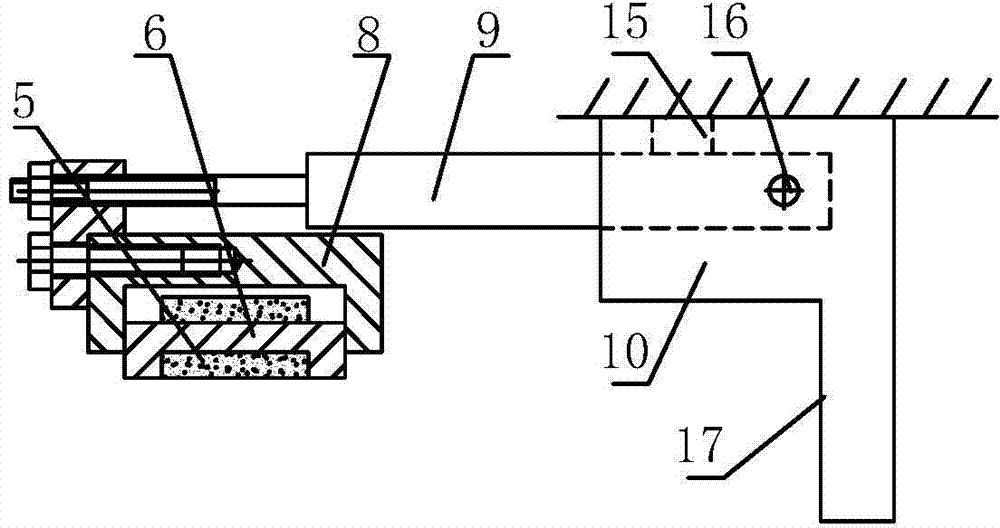

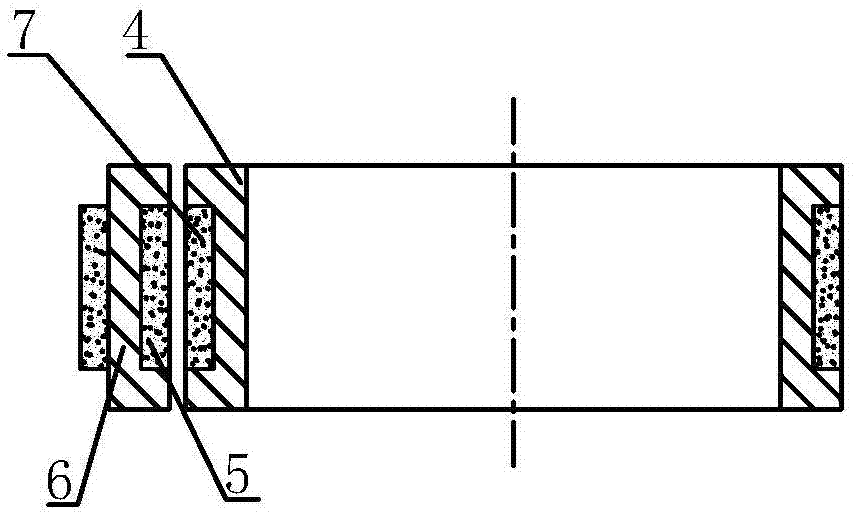

[0025] Such as figure 1 As shown, the present invention is based on a local induction rotary ultrasonic head of a machine tool attachment, including a tool handle 3 connected to an ultrasonic vibration working device and a non-contact collector ring, and one end of the tool handle 3 is connected to the The ultrasonic vibration working device is connected, where the precision of the tool handle 3 and the flange contact surface is required to be high, otherwise the coaxial arrangement of the tool 1, the horn 2 and the tool handle 3 cannot be realized, which affects the processing quality; the tool handle The other end of 3 is installed on the main shaft of the machine tool, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com