Cutting device for direct burial PVC pipe

A PVC pipe and cutting device technology, applied in metal processing and other directions, can solve the problems of unsecured staff safety, inability to complete flow operations, and inability to accurately cut, achieve good cutting effect, prevent accidental operator injury, and accurately cut Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

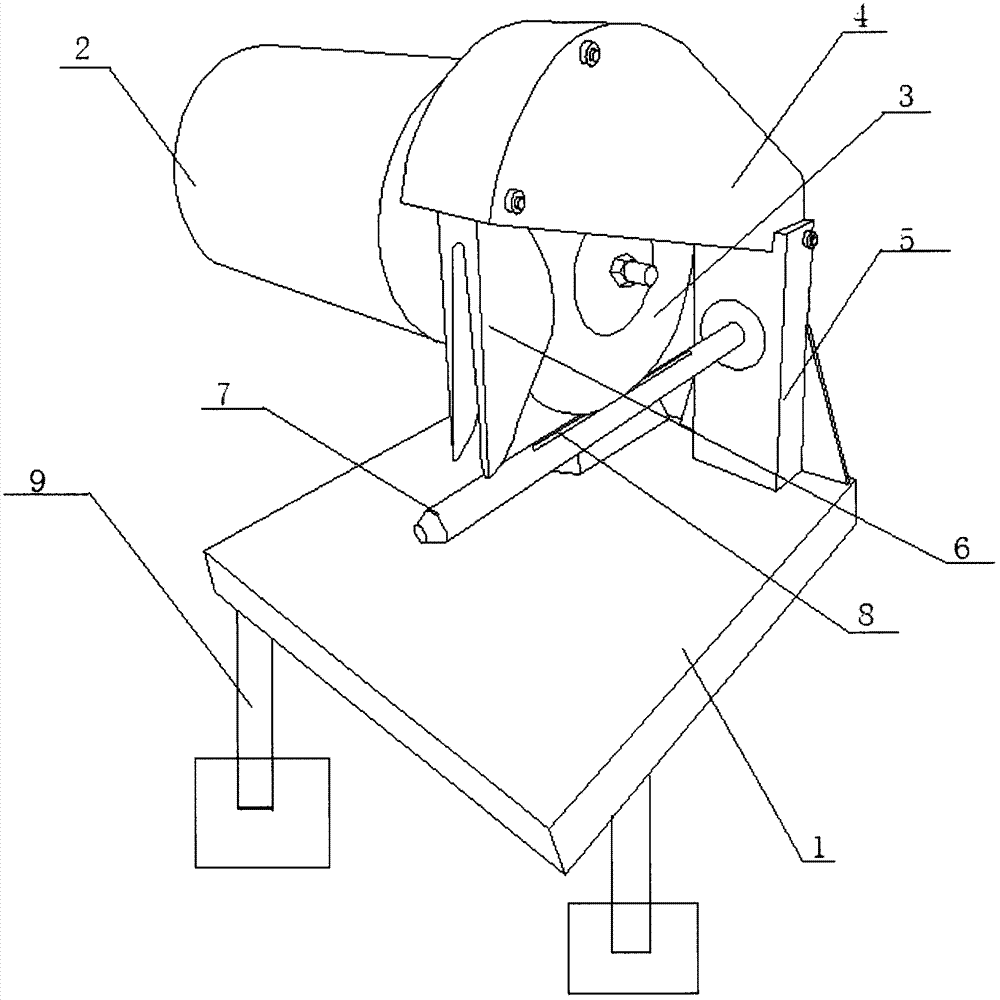

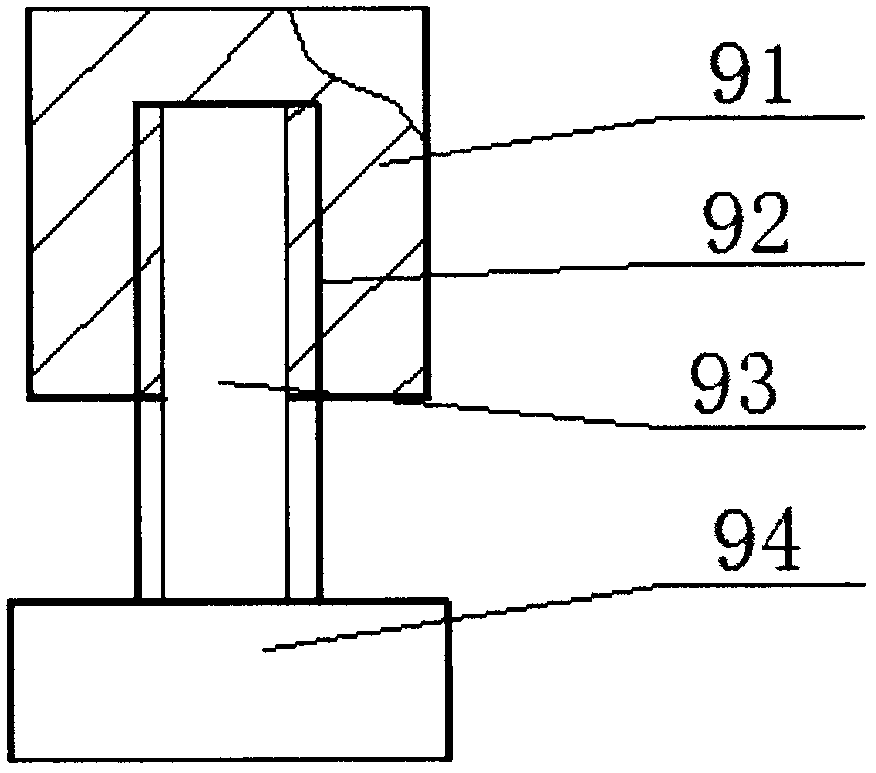

[0016] Such as figure 1 As shown, a direct-buried PVC pipe cutting device of the present invention includes a base 1, a motor 2 is arranged on the base 1, a cutting saw blade 3 is connected to the motor 2, and a Housing 4, the housing 4 is fixed by the column 5 fixed on the base 1; in order to prevent the cutter from cutting, a stopper 6 is provided in front of the cutting saw blade 3, and the stopper 6 can be opposite to the The cutting saw blade 3 moves backward; the bottom of the base 1 is equipped with a lifting device 9, and the lifting device 9 includes several connecting blocks 91, and the middle part of the connecting block 91 offers a second screw hole 92, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com