Composite fiber board and manufacturing method thereof

A technology of composite fiber and plywood, which is applied in the field of composite materials to achieve the effects of low water absorption thickness expansion ratio, excellent mechanical properties, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of composite fiberboard, its composition is as follows:

[0035] 30 parts of lignocellulose;

[0036] 13 pieces of bamboo chips;

[0037] 20 copies of YJ-3 special glue for formaldehyde-free plywood;

[0038] The method for manufacturing the composite fiberboard of this embodiment may further comprise the steps:

[0039] (1) Lignocellulose and bamboo chips are pulverized respectively by weight, and the particle size of each raw material mentioned above is pulverized to 300 orders;

[0040] (2) drying lignocellulose and bamboo chips after step (1) is ground, and mixing uniformly;

[0041] (3) Place the lignocellulose and bamboo chips mixed uniformly in the previous step at room temperature, and then add YJ-3 formaldehyde-free plywood special glue and stir until uniform;

[0042] (4) The fiberboard material in step (3) is pressurized in a mould, the temperature is 50° C., and the pressure is 2 MPa.

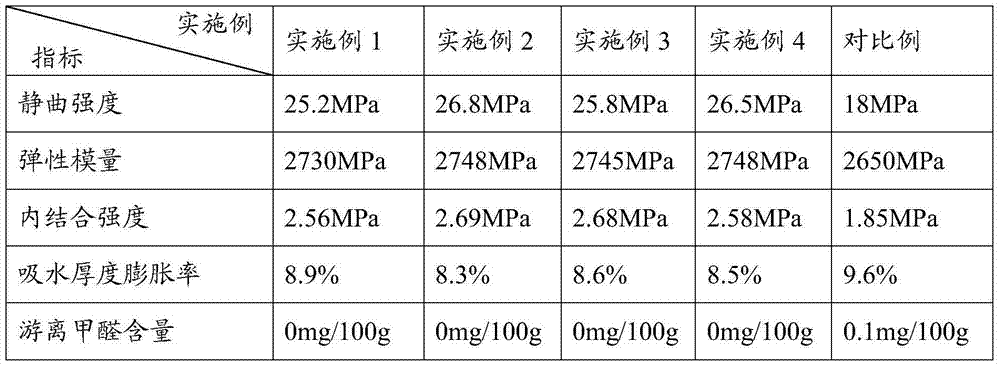

[0043] The obtained fiberboard is subjected to performance t...

Embodiment 2

[0045] A kind of composite fiberboard, its composition is as follows:

[0046] 35 parts of lignocellulose;

[0047] 12 parts of bamboo chips;

[0048] 15 copies of YJ-3 special glue for formaldehyde-free plywood.

[0049] The method for manufacturing the composite fiberboard of this embodiment may further comprise the steps:

[0050] (1) Lignocellulose and bamboo chips are pulverized respectively by weight, and the granularity of each raw material mentioned above is pulverized to 350 orders;

[0051] (2) drying lignocellulose and bamboo chips after step (1) is ground, and mixing uniformly;

[0052] (3) Place the lignocellulose and bamboo chips mixed uniformly in the previous step at room temperature, and then add YJ-3 formaldehyde-free plywood special glue and stir until uniform;

[0053] (4) The fiberboard material in step (3) is pressurized in a mould, the temperature is 55° C., and the pressure is 3 MPa.

Embodiment 3

[0055] A kind of composite fiberboard, its composition is as follows:

[0056] 35 parts of lignocellulose;

[0057] 15 parts of bamboo chips;

[0058] 20 copies of YJ-3 special glue for formaldehyde-free plywood;

[0059] The method for manufacturing the composite fiberboard of this embodiment may further comprise the steps:

[0060] (1) Lignocellulose and bamboo chips are pulverized respectively by weight, and the granularity of each raw material mentioned above is pulverized to 400 orders;

[0061] (2) drying lignocellulose and bamboo chips after step (1) is ground, and mixing uniformly;

[0062] (3) Place the lignocellulose and bamboo chips mixed uniformly in the previous step at room temperature, and then add YJ-3 formaldehyde-free plywood special glue and stir until uniform;

[0063] (4) The fiberboard material in step (3) is pressurized in a mould, the temperature is 55° C., and the pressure is 2.5 MPa.

[0064] The obtained fiberboard is subjected to performance te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com