Formaldehyde-free decorative wood panel and preparation method thereof

A technology of wood board and formaldehyde, applied in the field of formaldehyde-free decorative wood board and its preparation, can solve the problems of formaldehyde release endangering health, etc., and achieve the effect of low production cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

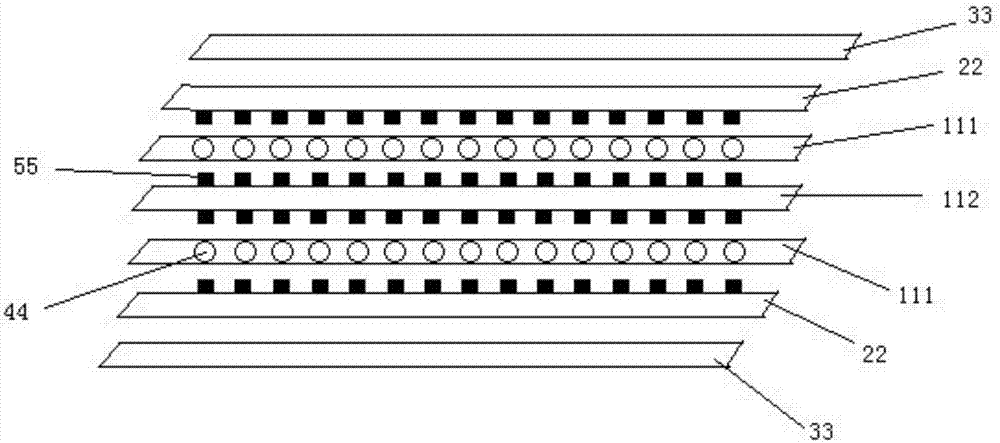

[0064] The invention discloses a formaldehyde-free decorative wood board and a preparation method thereof, wherein the formaldehyde-free decorative wood board embryo is composed of two layers of facing layers 33, two layers of hot-melt adhesive layers 22 and one formaldehyde-free base material layer. The two-layer hot-melt adhesive layer 22 is respectively located on the upper and lower layers of the formaldehyde-free substrate layer; the two-layer decorative layer 33 is respectively located on the two-layer hot-melt adhesive layer. upper and lower layers.

[0065] The formaldehyde-free substrate layer is made of two or more than two layers of formaldehyde-free substrate boards 111 bonded by hot-pressing and hot-melting, and there is a layer of hot-melt snap-bonding between the formaldehyde-free substrate boards 111 Layer 112, the above and below of the hot-melt snap-in adhesive layer 112 have evenly distributed glue nails 55, and the glue nails 55 on the hot-melt snap-in adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com