High performance environment friendly urea-formaldehyde resin adhesive and its preparing method and use

A urea-formaldehyde resin and adhesive technology, used in adhesives, aldehyde/ketone condensation polymer adhesives, chemical instruments and methods, etc., can solve the problems of increased product quality risk, poor production stability, and reduced production efficiency. The effect of large social environmental benefits and economic benefits, high bonding strength and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

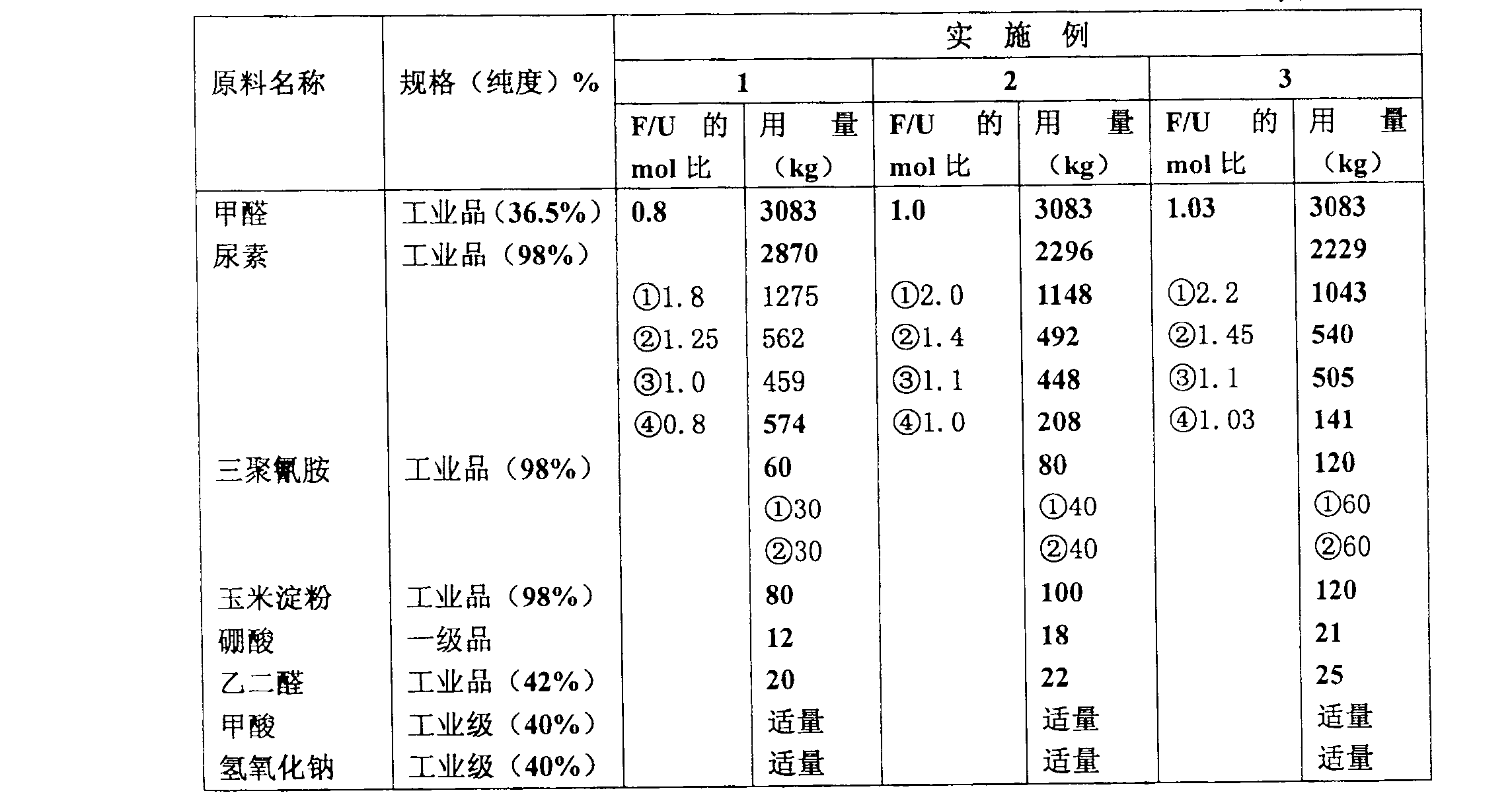

[0050] Embodiment 1-3: the preparation of urea-formaldehyde resin in the present invention

[0051] Raw materials used in each embodiment and consumption are as table 1

[0052] Table 1

[0053]

[0054] Preparation method: (taking Example 1 as an example, other examples are the same as Example 1 except the raw material consumption)

[0055] (1) Add 3083kg of formaldehyde to the reaction kettle at one time, add sodium hydroxide to adjust the pH value to 8.1 after heating up, when the reaction temperature is 40°C, add 1275kg of urea for the first time (the molar ratio of formaldehyde F to urea U is 1.8, see Table 1①).

[0056] (2) Within 30 minutes, the reaction temperature rises from 40°C to 80°C, and when the reaction temperature is about 50-56°C, the steam is turned off to stop heating, and the reaction temperature rises naturally. Insulation reaction at 80-88°C for 30 minutes, when the measured pH value dropped to 6.7, add 12kg boric acid and adjust the pH value to 5....

Embodiment 4-6

[0060] Embodiment 4-6: the preparation of curing agent in the present invention

[0061] The raw materials and consumption used in each embodiment are shown in Table 2.

[0062] Table 2

[0063] Example 4 5 6 ammonium chloride 150kg 180kg 200kg Ferric chloride 80kg 120kg 150kg water 500kg 650kg 800kg

[0064] Preparation method: (taking Example 4 as an example, other examples are the same as Example 4 except the raw material consumption)

[0065] Grind 150kg of ammonium chloride and 80kg of ferric chloride to a fine powder of 500 mesh or more, then slowly and evenly disperse them into 500kg of water at 40-60°C to obtain a curing agent.

Embodiment 7-12

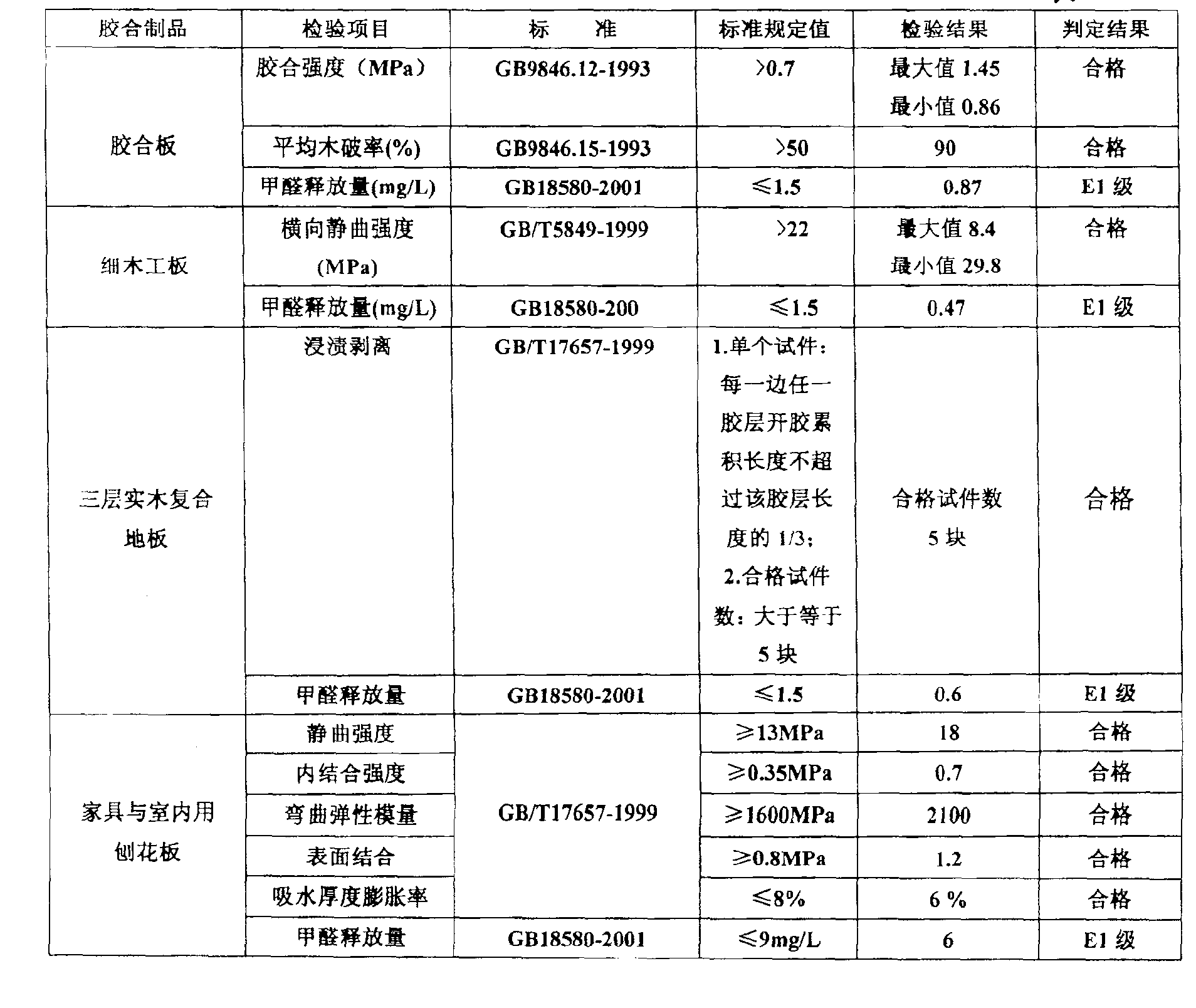

[0066] Embodiment 7-12: the application of adhesive of the present invention

[0067] The raw materials and consumptions used in each embodiment are shown in Table 3.

[0068] table 3

[0069] Example 7 8 9 10 11 12 Urea-formaldehyde resin 100kg 100kg 100kg 100kg 100kg 100kg Composite filler 10kg 15kg 20kg 0 0 0 Paper waste liquid 0 0 0 2kg 3kg 4kg Hardener 8kg 7kg 5kg 3kg 4kg 5kg

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| release amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com