A kind of three-dimensional picture, preparation method and application thereof

A technology for three-dimensional paintings and carriers, applied in the field of preparation and three-dimensional paintings, can solve the problems of single function and need to be improved in practicability, and achieve the effects of avoiding monotony, increasing anti-counterfeiting and aesthetics, and increasing aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

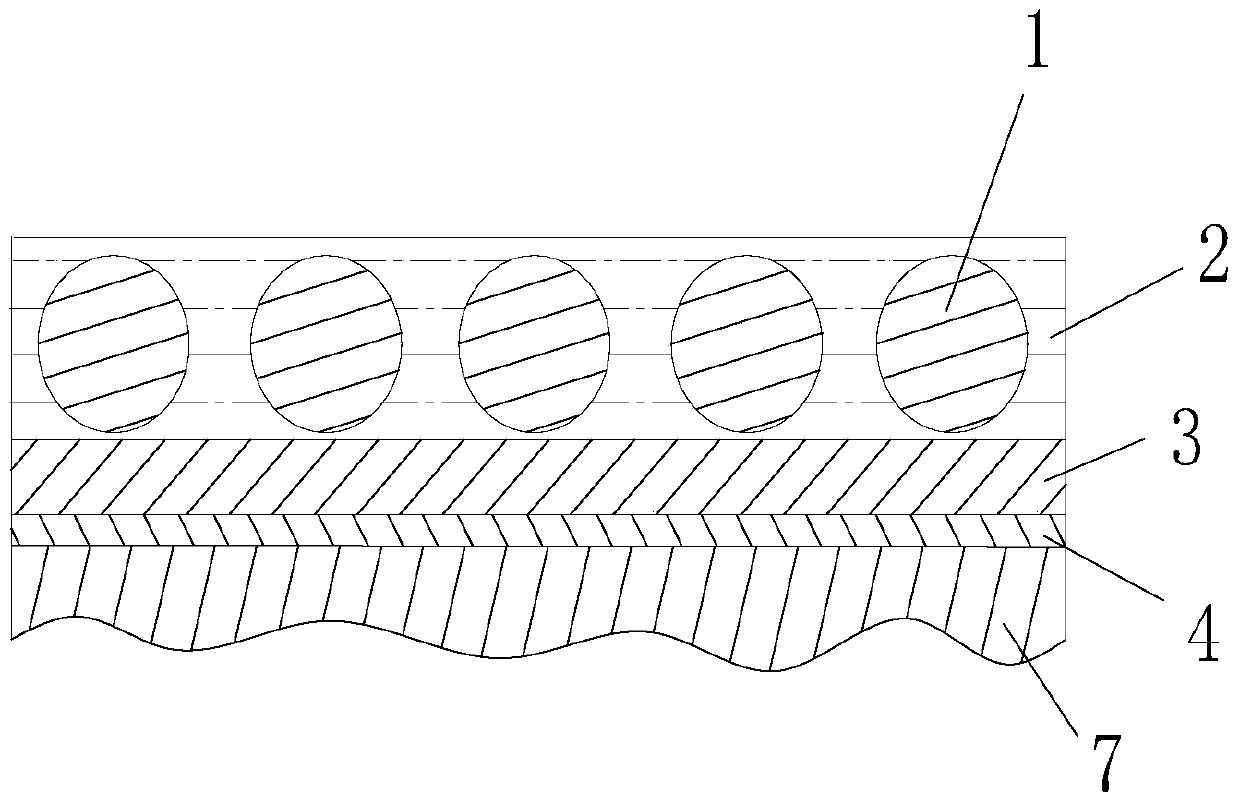

[0050] The preparation method of the three-dimensional picture in the first embodiment of the present invention includes the following steps:

[0051] (1) Prepare a release carrier 5 with a release layer 9 on the release carrier;

[0052] (2) Adhere the optical element 1 that has been electroplated in advance and can reflect white or colorful light on the surface of the release layer 9 through an adhesive to form a reflective layer 2;

[0053] (3) An attachment layer 3 is formed on the bottom surface of the reflective layer 2;

[0054] (4) Paint or print colors or a first pattern on the bottom surface of the attachment layer 3 to form a first color layer 4;

[0055] (5) The attachment layer 3 is attached to a transparent layer 7 with a three-dimensional effect, so that the first color layer 4 is located between the attachment layer 3 and the transparent layer 7;

[0056] Wherein, the transparent layer 7 may be embossed before being attached to the attachment layer 3, or may be embossed a...

Embodiment 5

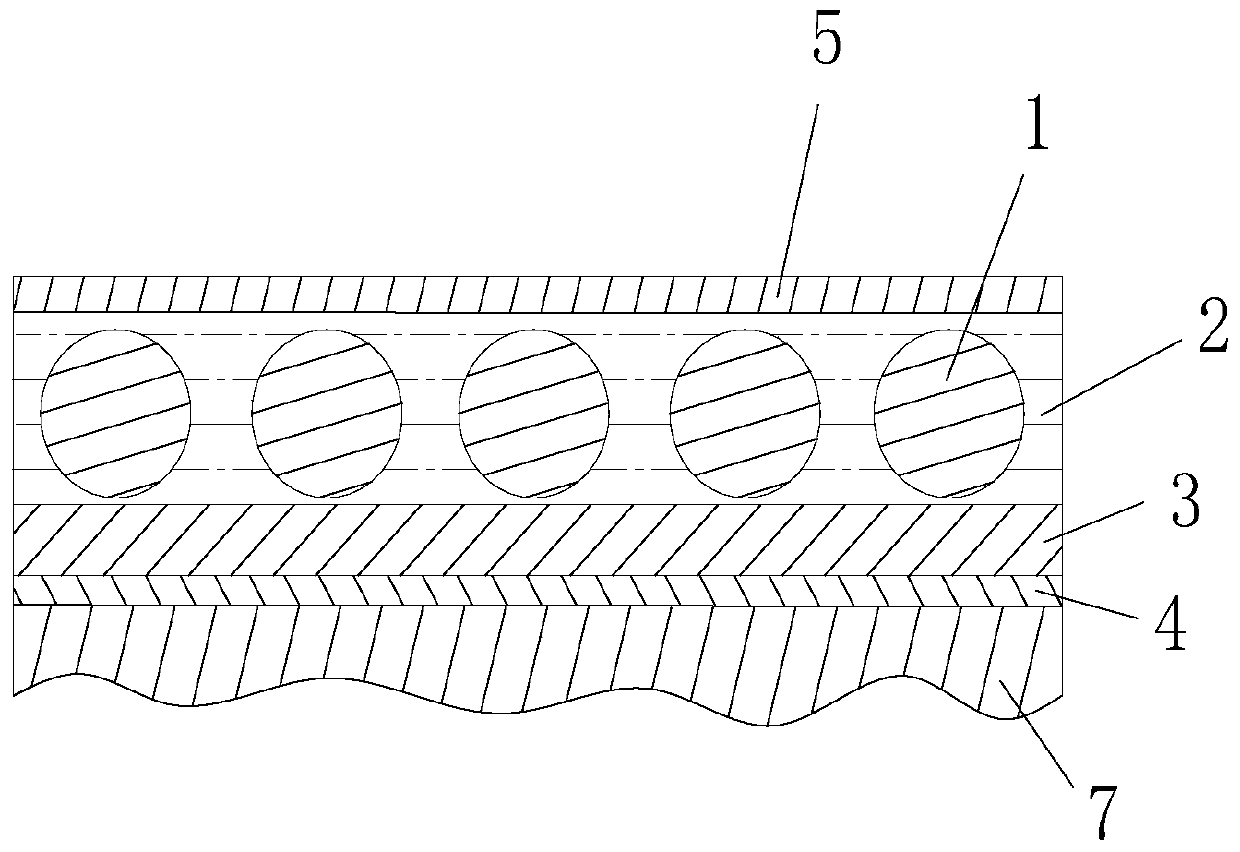

[0087] Please refer to Figure 5 , The fifth embodiment of the present invention provides another three-dimensional picture, which includes the following layered structures arranged in sequence: a reflective layer 2 formed by bonding a plurality of optical elements 1 through an adhesive; one located on the bottom surface of the reflective layer 2 The electroplating layer 8; an attachment layer 3 located on the bottom surface of the electroplating layer 8; a first color layer 4; a transparent layer 7 with a three-dimensional effect that can be embossed. The difference between the three-dimensional picture described in the fifth embodiment of the present invention and the three-dimensional picture described in the first embodiment is that the optical element 1 does not need to be electroplated in advance, but the optical element 1 is glued together by an adhesive. After the light-reflecting layer 2, the bottom surface of the light-reflecting layer 2 is electroplated with an electr...

Embodiment 6

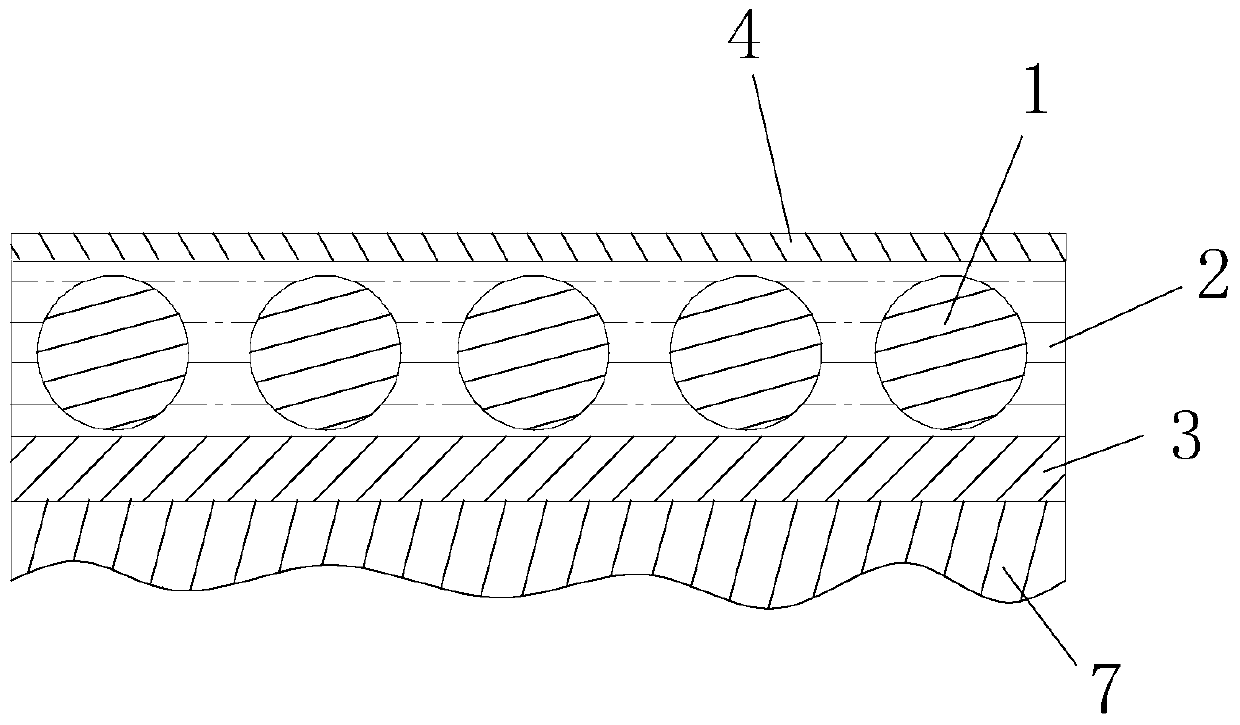

[0098] Please refer to Image 6 The sixth embodiment of the present invention provides another three-dimensional picture, which includes the following layered structures arranged in sequence: a reflective layer 2 made of a plurality of optical elements 1 bonded by an adhesive; a first color layer 4 ; A transparent layer 7 that can be embossed to create a three-dimensional effect. The difference between the three-dimensional picture described in the sixth embodiment of the present invention and the three-dimensional picture described in the first embodiment is that the transparent layer 7 is directly attached to the bottom surface of the reflective layer 2 without an attachment layer.

[0099] The preparation method of the three-dimensional picture in the sixth embodiment of the present invention includes the following steps:

[0100] (1) Prepare a release carrier 5 with a release layer 9 on the release carrier;

[0101] (2) Adhere the optical element 1 that has been electroplated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com