Vehicle cooling circuit

A cooling circuit and coolant pipeline technology, applied in liquid cooling, vehicle components, vehicle energy storage, etc., can solve the problems of output refrigeration power, refrigerator can not, cooling liquid can not be reduced according to needs, etc., to achieve a simplified system architecture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

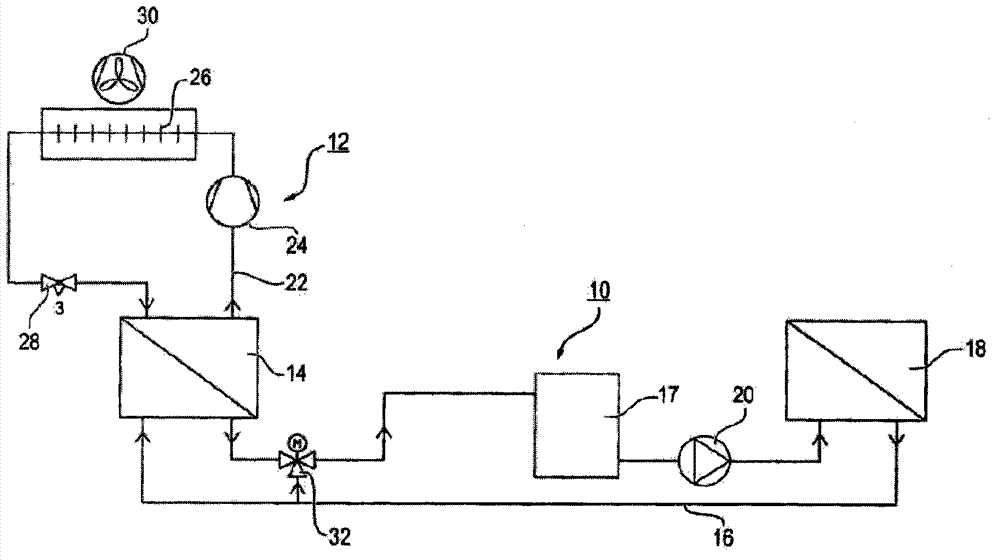

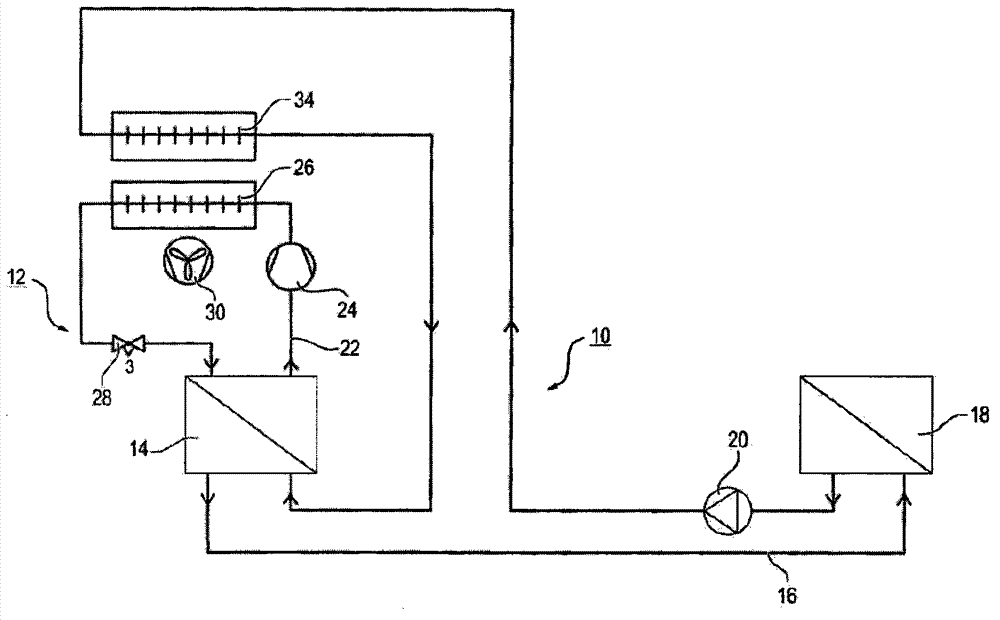

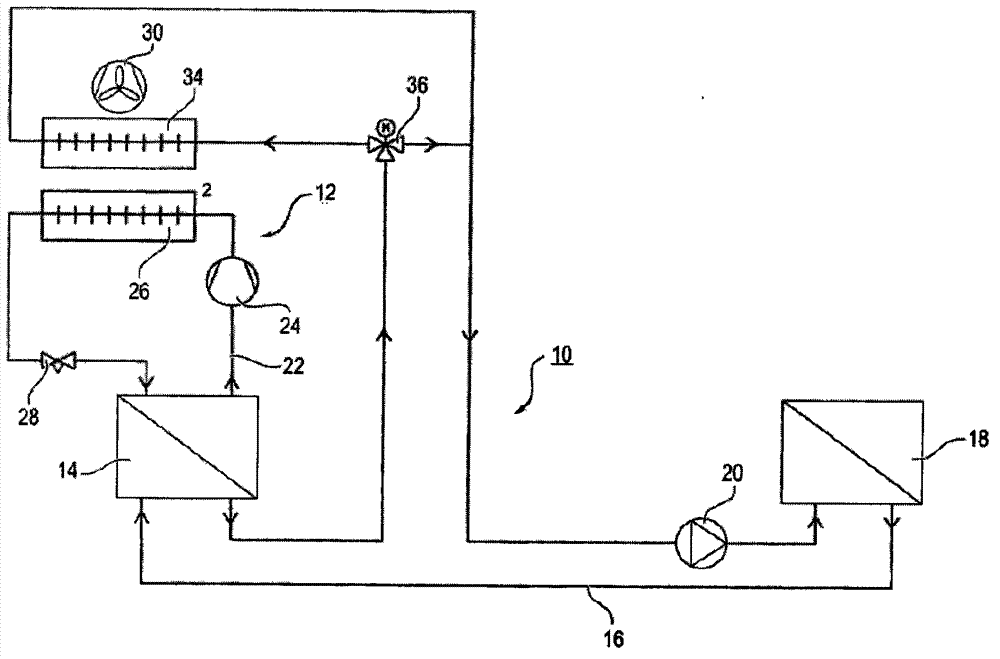

[0019] Such as image 3 As shown, the coolant circuit 10 of the first embodiment of the invention is connected to the cooling medium circuit 12 via a heat exchanger 14 configured as an evaporator. The coolant circuit has a coolant line 16 in which the coolant is passed by a pump 20 along the image 3 Convey in the direction of the arrow shown. The heated device 18 , for example the vehicle battery of an electric vehicle, is cooled by the coolant. Furthermore, the coolant circuit is provided with a refrigerant 34 which is cooled by a cooling air flow which is cooled by the airflow of the vehicle and / or by the fan 30 . Further cooling of the coolant circuit takes place via a heat exchanger 14 configured as an evaporator in a cooling medium circuit connected to the coolant circuit. In a known manner, the coolant circuit 12 comprises, in addition to the evaporator 12 , a coolant line 22 , a compressor 24 , a condenser 26 and a pressure relief valve 28 . The aforementioned word "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com