Payoff cart for lead threading construction

A technology of pay-off car and pipe threading, which is applied in the direction of conveying filamentous materials, cable laying equipment, thin material processing, etc., and can solve the problems that the wire reel is easy to be scattered, affects the speed of threading construction, and is easy to get stuck in the bend of the pipe, etc. , to improve the construction speed and construction quality, the connection method is simple and fast, and the design is novel and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

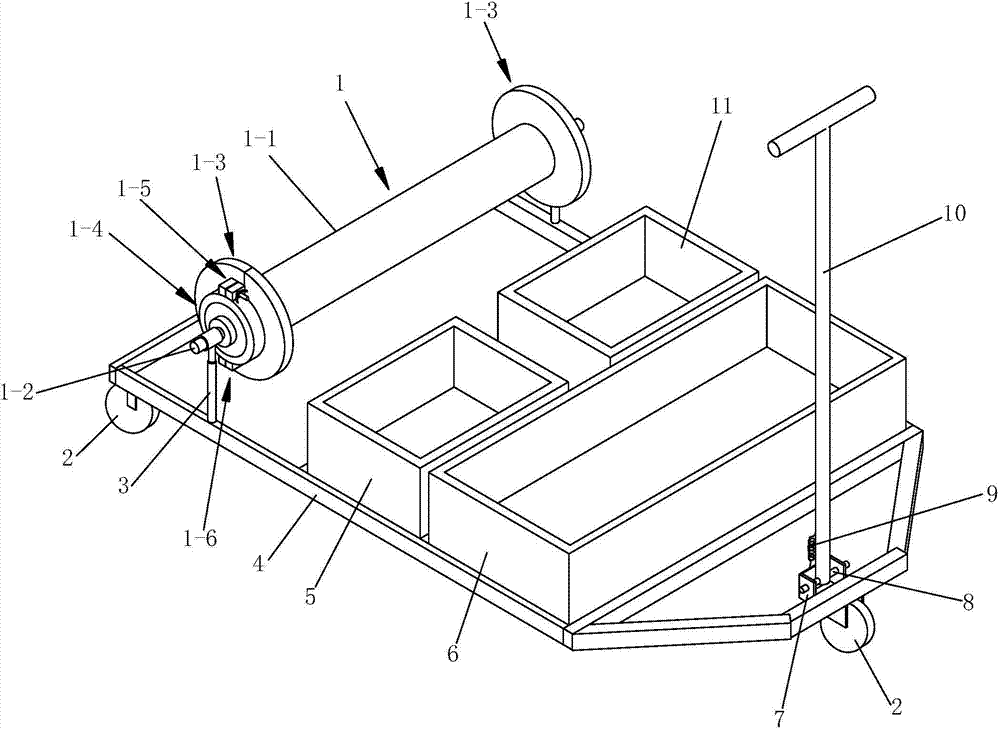

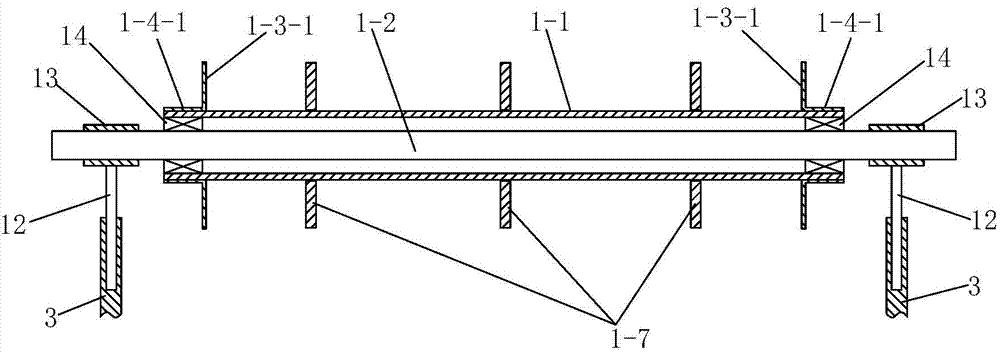

[0053] Such as figure 1 A pay-off vehicle for wire threading construction is shown, which includes a pay-off roller assembly 1 and a frame 4, and the frame 4 is provided with traveling wheels 2; the pay-off drum assembly 1 includes a central shaft 1-2 and a pay-off drum body 1-1 for installing a reel, the central axis 1-2 is set in the pay-off drum body 1-1 and the pay-off drum body 1-1 is connected to the central shaft 1-2 rotation fit, the frame 4 is provided with two fixed sleeves 3, and the two ends of the central shaft 1-2 are connected to the two fixed sleeves 3 one by one through the plug-in structure Connected, the two ends of the pay-off drum body 1-1 are equipped with detachable baffles for preventing the wire reel from falling off.

[0054] In this embodiment, when the pay-off vehicle for wire threading construction is in use, the wire reel is installed on the pay-off drum body 1-1, and when the wire is threaded through the pipe, the wire end on the wire reel is pu...

Embodiment 2

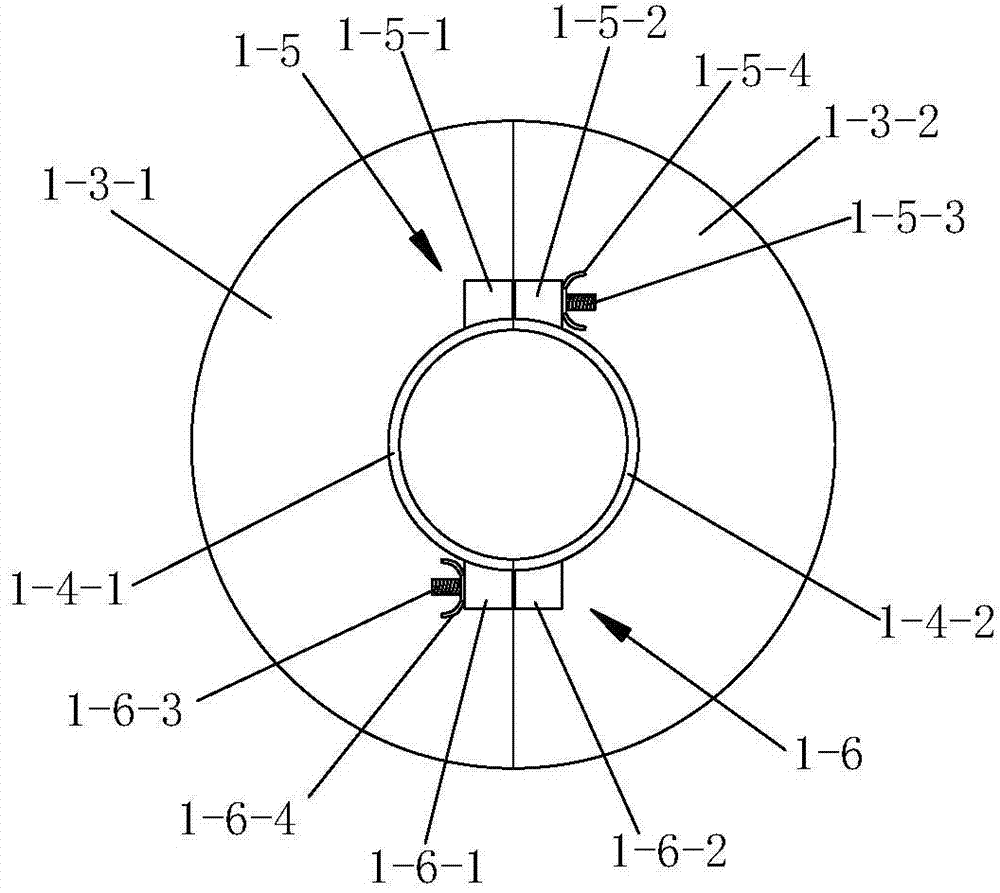

[0068] Such as Figure 4 and Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the detachable baffle includes a baffle body 1-3 and a center sleeve 1-4 that is sleeved on the pay-off drum body 1-1; The baffle body 1-3 is composed of a semicircular first baffle unit 1-3-1 and a semicircular second baffle unit 1-3-2; the center sleeve 1-4 is composed of a semicircular The ring-shaped first center sleeve unit 1-4-1 and the semi-circular second center sleeve unit 1-4-2 are spliced together, and the first center sleeve unit 1-4-1 is arranged on the first baffle unit 1 -3-1, the second center sleeve unit 1-4-2 is set on the second disc unit 1-3-2, one end of the first disc unit 1-3-1 and the second disc unit One end of the disc unit 1-3-2 is connected by a first locking member 1-8, and the other end of the first disc unit 1-3-1 and the other end of the second disc unit 1-3-2 are connected by The second locking elements 1-9 are connected.

[00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap