Dyeing method of knitted fabric embryo

A technology for knitted fabric blank and dyeing method, applied in the field of dyeing, can solve the problems of many types of chemicals, low K/S value, low color fastness, etc., and achieves improved dyeing quality, K/S value, and color fastness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

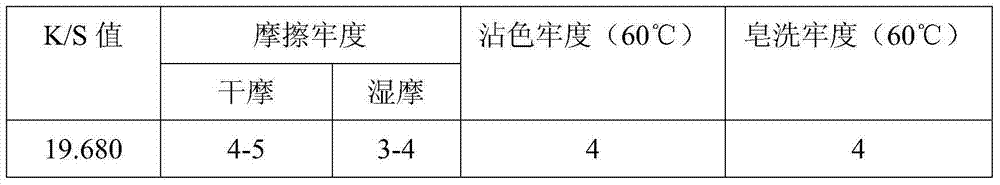

Embodiment 1

[0013] A method for dyeing knitted fabric embryos, comprising soaking, heating, washing, soaping, drying and testing. The specific steps are as follows:

[0014] (1) Soaking: Put the disperse dye into the container, add water to a ratio of 1.0g / L, and then add reactive dye, anhydrous sodium sulfate, and pH buffer, the disperse dye is 1%, and the The active dye is 3%, the anhydrous sodium sulfate is 30g / L, and the pH buffer is 3%. The knitted fabric embryo is soaked at room temperature for 50 minutes.

[0015] (2) Heating: first, the above system was heated to 70°C at a rate of 2.5°C / min and kept for 12 minutes; then heated to 120°C at a rate of 1.5°C / min and kept for 12 minutes; finally at a rate of 2°C / min Cool down to 70°C-90°C and keep it for 12min.

[0016] (3) Water washing: wash 5 times with cold water at normal temperature until the pH value of the cleaning solution for cleaning the knitted fabric embryo is between 6.9-7.1.

[0017] (4) Soaping: Soap flakes 5g / L, anh...

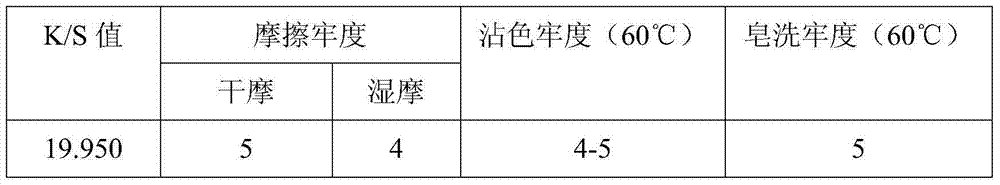

Embodiment 2

[0024] A method for dyeing knitted fabric embryos, comprising soaking, heating, washing, soaping, drying and testing. The specific steps are as follows:

[0025] (1) Soaking: Put the disperse dye into the container, add water to a ratio of 1.5g / L, then add reactive dye, anhydrous sodium sulfate, pH buffer, the disperse dye is 2%, the The active dye is 2%, the anhydrous sodium sulfate is 40g / L, and the pH buffer is 2%, and the knitted fabric is soaked at room temperature for 60 minutes.

[0026] (2) Heating: first, the above system was heated to 80°C at a rate of 2.5°C / min and kept for 13 minutes; then heated to 130°C at a rate of 1.5°C / min and kept for 13 minutes; finally at a rate of 2°C / min Cool down to 80°C and keep for 13min.

[0027] (3) Water washing: wash 6 times with cold water at normal temperature until the pH value of the cleaning solution for cleaning the knitted fabric embryo is between 6.9-7.1.

[0028] (4) Soaping: Soap flakes 5g / L, anhydrous sodium carbonate...

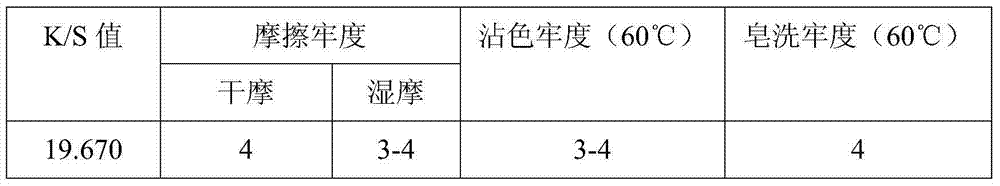

Embodiment 3

[0035] A method for dyeing knitted fabric embryos, comprising soaking, heating, washing, soaping, drying and testing. The specific steps are as follows:

[0036] (1) Soaking: Put the disperse dye into the container, add water to a ratio of 2.0g / L, then add reactive dye, anhydrous sodium sulfate, pH buffer, the disperse dye is 3%, the The active dye is 1%, the anhydrous sodium sulfate is 50g / L, and the pH buffer is 1%, and the knitted fabric is soaked at room temperature for 70 minutes.

[0037] (2) Heating: first, the above system is heated to 90°C at a rate of 2.5°C / min and kept for 14 minutes; then heated to 140°C at a rate of 1.5°C / min and kept for 14 minutes; finally at a rate of 2°C / min Cool down to 90°C and keep for 14min.

[0038] (3) Water washing: wash 5-7 times with cold water at normal temperature until the pH value of the cleaning solution for cleaning the knitted fabric embryo is between 6.9-7.1.

[0039] (4) Soaping: Soap flakes 5g / L, anhydrous sodium carbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com