Method for constructing connecting steel corridors

A technology of steel corridors and corridors, which is applied in the direction of construction, building structure, and building materials processing. It can solve the problems of overall structure vibration, unfavorable safety targets, and inability to ensure structural safety. It achieves simple and convenient fastening and releasing operations. Ease of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0040] The invention proposes a construction method for connecting steel corridors.

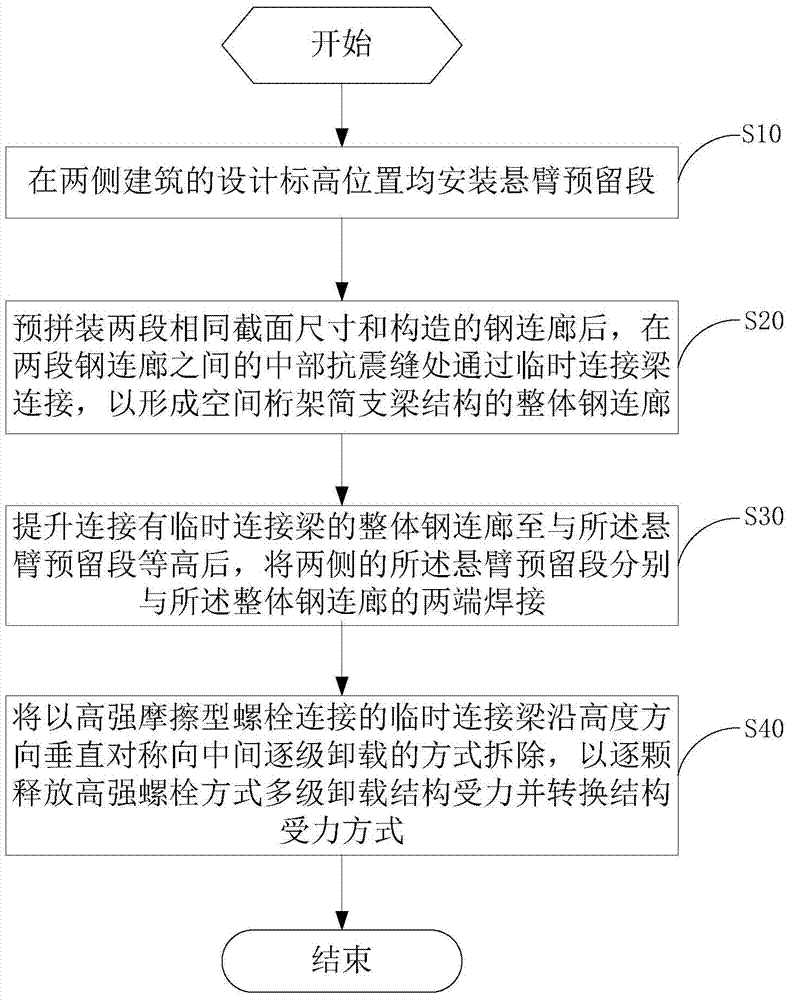

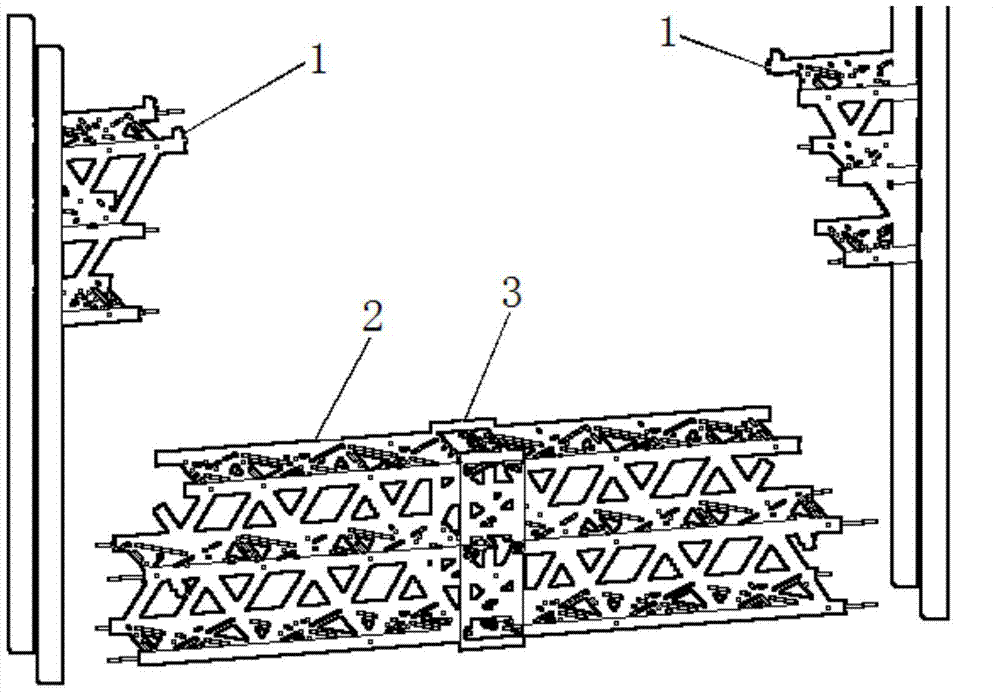

[0041] refer to figure 1 and figure 2 , figure 1 It is a schematic flow diagram of a preferred embodiment of the construction method of the connecting steel gallery of the present invention, figure 2 It is a structural schematic diagram of the connecting steel corridor of the present invention.

[0042] In this preferred embodiment, the construction method for connecting the steel gallery includes the following steps:

[0043] Step S10, install the cantilever reserved section 1 at the design elevation positions of the buildings on both sides;

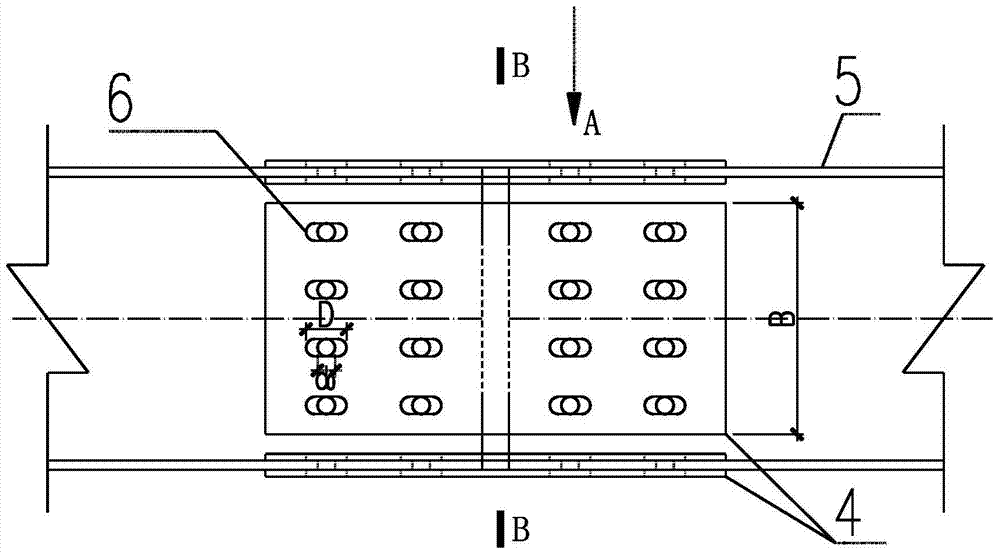

[0044] Step S20, after pre-assembling two sections of steel corridors with the same cross-sectional size and structure, connect them through the temporary connecting beam 3 at the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com