A method of cracking the left filling wall of adjacent coal mining face

A technology for coal mining face and wall filling, which is applied to filling materials, mining equipment, earthwork drilling and mining, etc. It can solve the problems of hidden safety hazards in adjacent coal seams, failure to achieve continuous pressure relief, damage bearing capacity, etc. The effect of low strength, less working time, and large expansion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

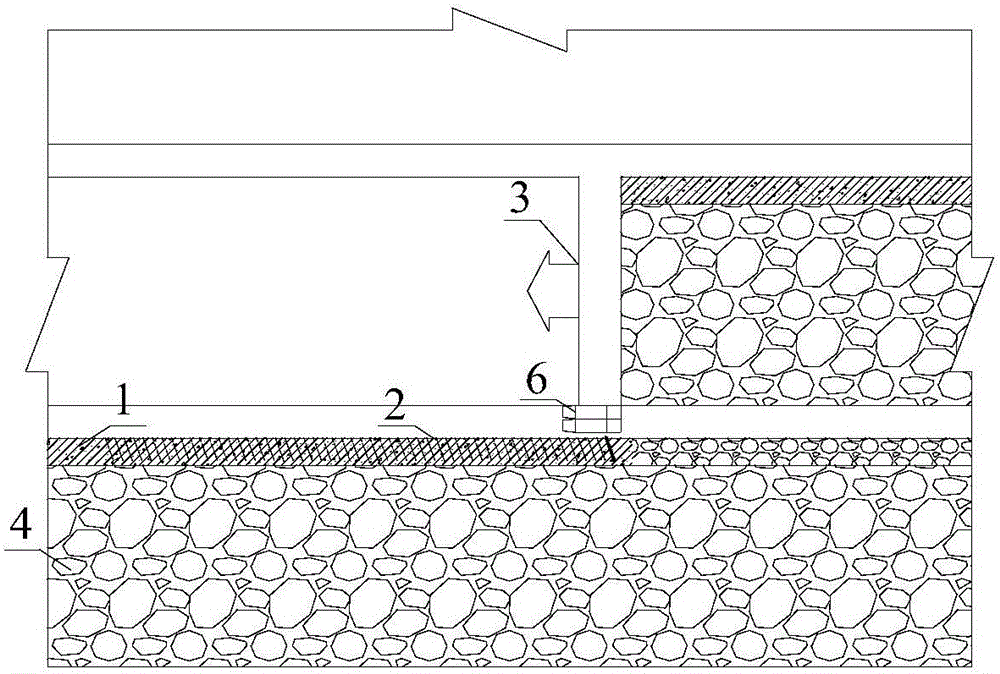

[0030] Example 1. The adjacent coal mining face 4 of a certain mine retains the reusable filling wall 1 width × height = 3m × 2.6m, which is constructed by pumping C30 paste material and supplemented by shear anchors. During the mining of coal mining face 3, the peak value of stress concentration appeared at 13m ahead of the working face, and the stress concentration factor reached 1.67. The overall quality of filling wall 1 near here was good, and a few cracks appeared on the surface.

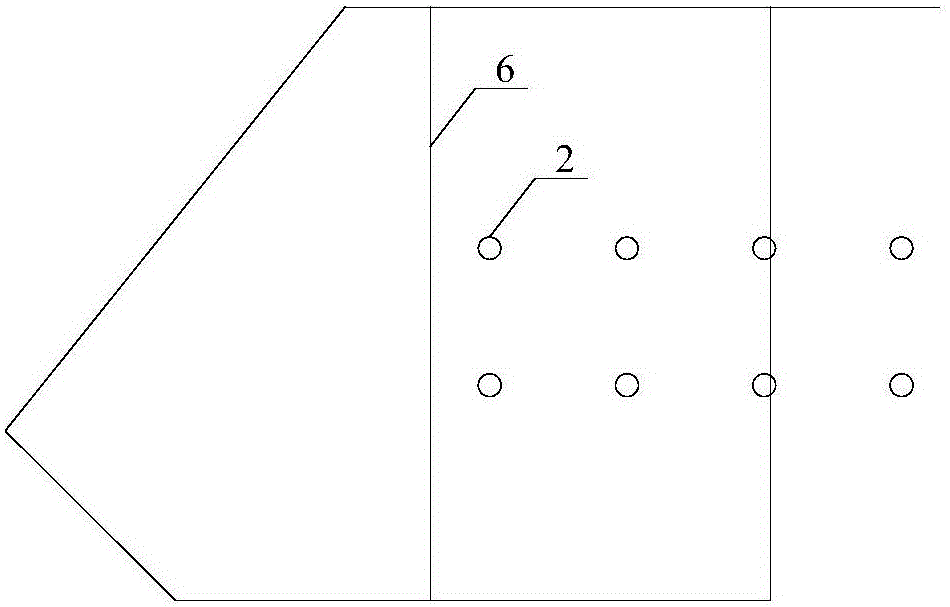

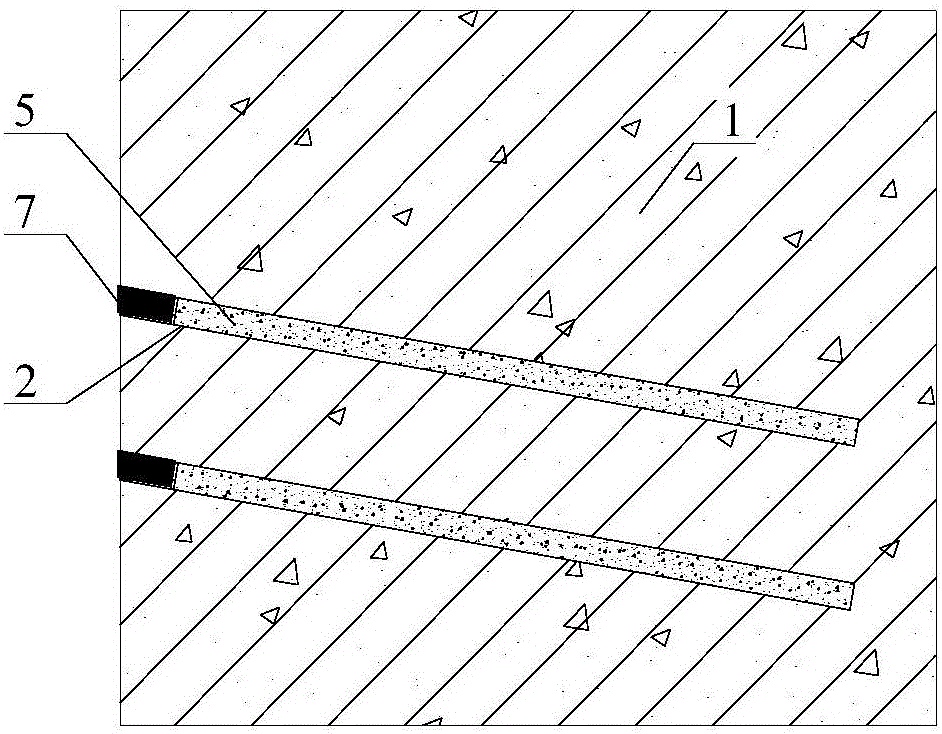

[0031] The distance between the advanced coal mining face 3 is 30m, and 2 rows of inclined downward drilling 2 are constructed in the roadway towards the filling wall 1. The inclination angle is 15°, the hole diameter is 50mm, the hole distance is 0.6m, the row distance is 0.6m, and the distance between the holes and the roof is 1.0m. 1.0m from the bottom plate, 25cm from the bottom of the hole to the other side of the filling wall 1.

[0032] Coal mining and charging operations are carried ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com