Inflatable unfolding composite material structure capable of being stiffened

A composite material, inflatable deployment technology, applied in inflatable space structures, space navigation equipment, chemical instruments and methods, etc., can solve the problems of stress concentration at the crease, low deployment shape accuracy, poor mechanical properties, etc., and achieve reliability. High, highly designable, high-precision unfolded shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

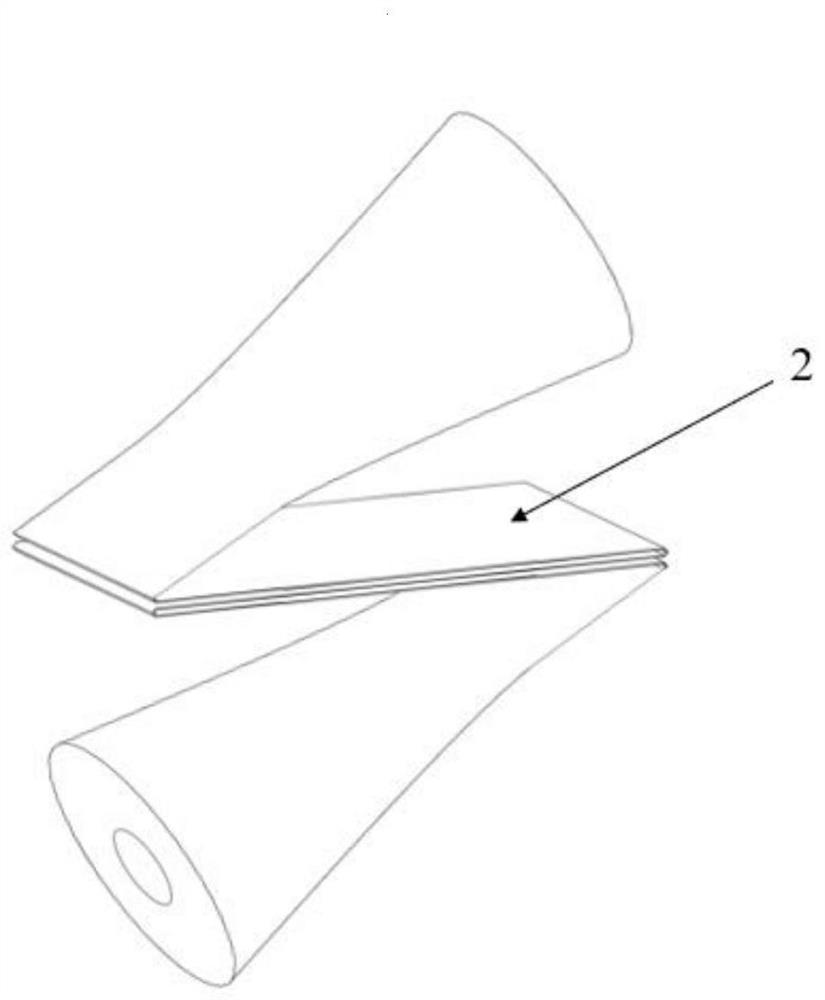

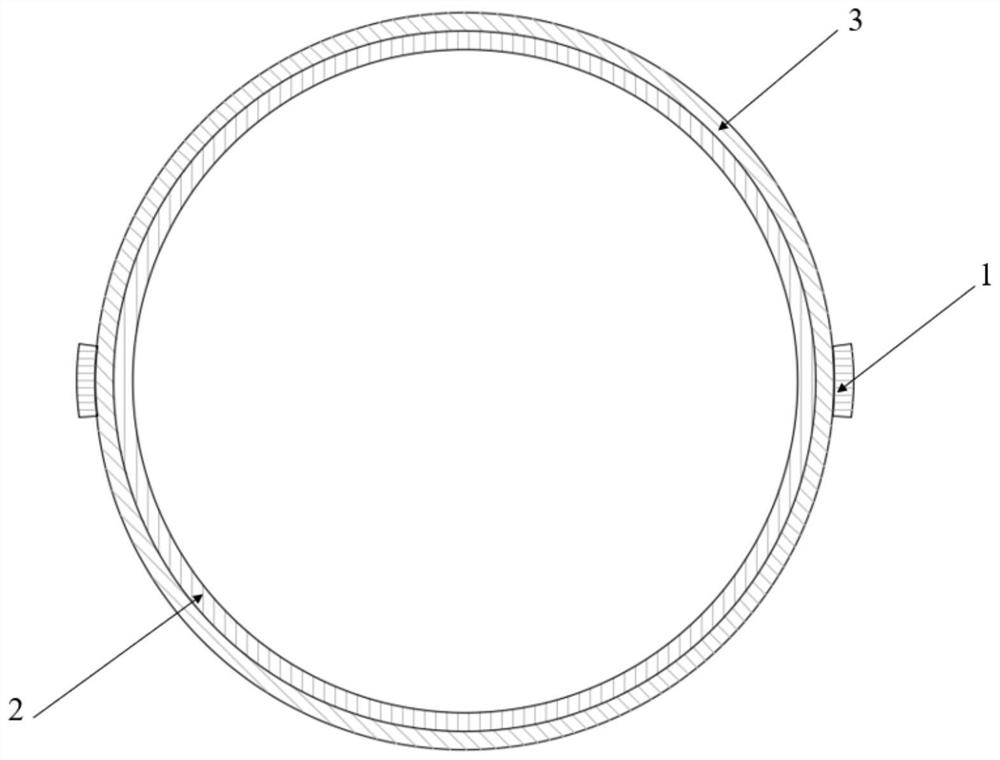

[0023] The invention provides an inflatable and expandable composite material structure which can be stiffened, which is composed of an inner tank, composite materials, heating sheets and end covers. The original configuration of the inflatable unfolded composite material structure is transformed into a folded form through a specific folding method. Here, the Z-shaped folding method is adopted. The cross-section is divided into two parts. The outer layer is composite material, and the inner layer is the inner tank. Polymer materials are polyethylene, polytetrafluoroethylene, epoxy resin, styrene, styrene-butadiene, trans polyisoprene, cyanate ester, polyurethane, chlorinated polyethylene, polyvinyl alcohol , Butyl Rubber, Inflatable Expanded Composite Structure The "matrix material" mentioned in the construction is epoxy resin, polyimide res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com