car electric fuel pump

An electric fuel pump, automobile technology, applied in the direction of pumps, pump components, engine components, etc., can solve the problems of adverse driving safety, oil leakage prevention, pressure rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

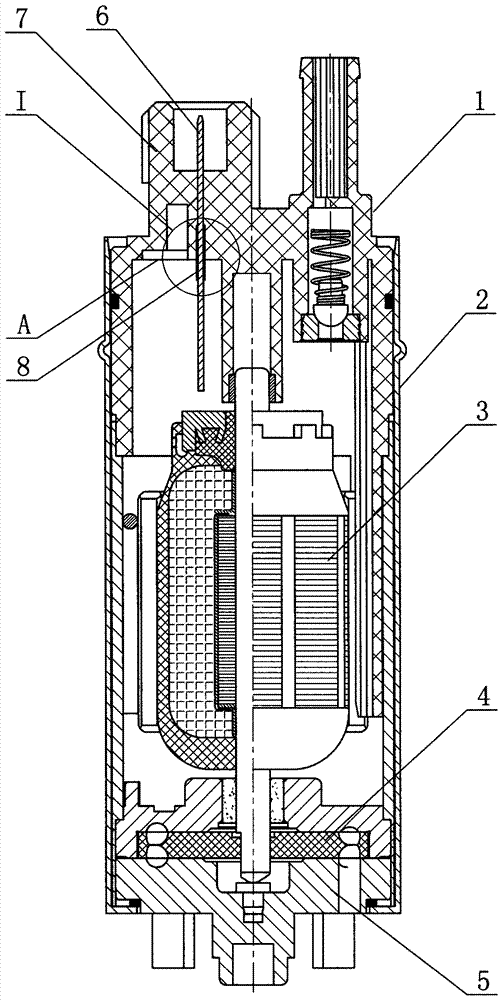

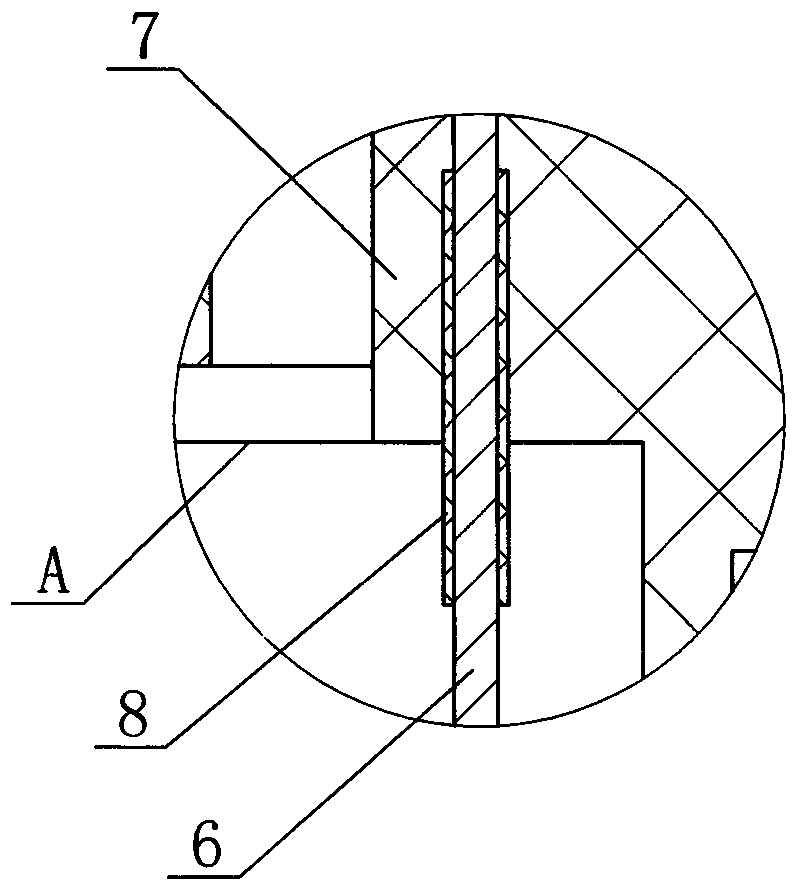

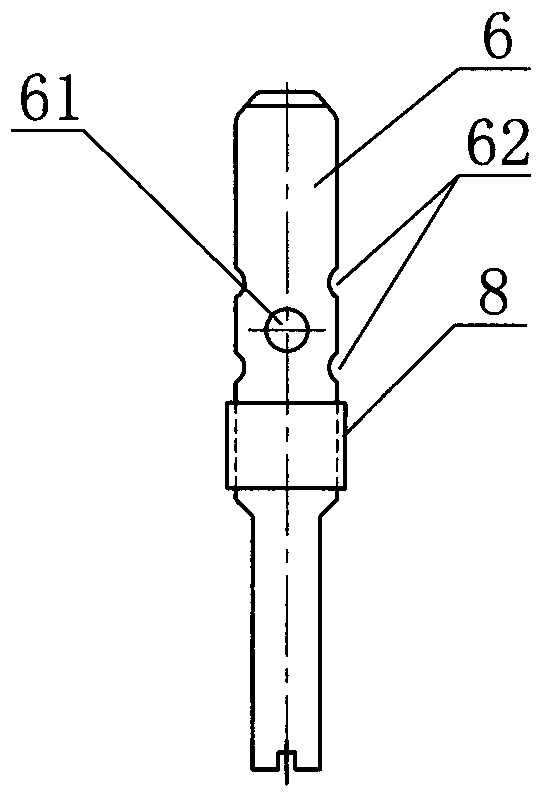

[0012] As shown in the figure, the automobile electric fuel pump of the present invention includes a pump casing 2, a pump head part 1, a rear cover assembly 5, a motor part 3 and a pump body part 4 installed in the pump casing 2, and the pump head part 1 It includes a pump cover 7 of plastic material and positive and negative inserts 6 fixed on the pump cover 7. The positive and negative inserts 6 run through the upper and lower end surfaces of the pump cover 7, and the lower part of the positive and negative inserts 6 and the pump cover 7 are connected. The semi-peripheral fixing sleeve is provided with a sealing ring 8, and the lower end of the sealing ring 8 leaves a certain distance (generally about 1 cm) from the lower end surface A of the pump cover 7, and the positive and negative pole inserts 6, the sealing ring 8 and the pump cover 7 are integrally injection molded. The sealing ring 8 is made of fluorosilicone rubber material, and the sealing ring 8 is fixedly sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com