Magnetically-driven submerged liquid chlorine pump

A magnetic drive, liquid chlorine pump technology, applied in the field of liquid chlorine pumps, can solve the problems of medium leakage, easy damage of isolation sleeves, etc., to avoid corrosion, ensure transmission efficiency and stability, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

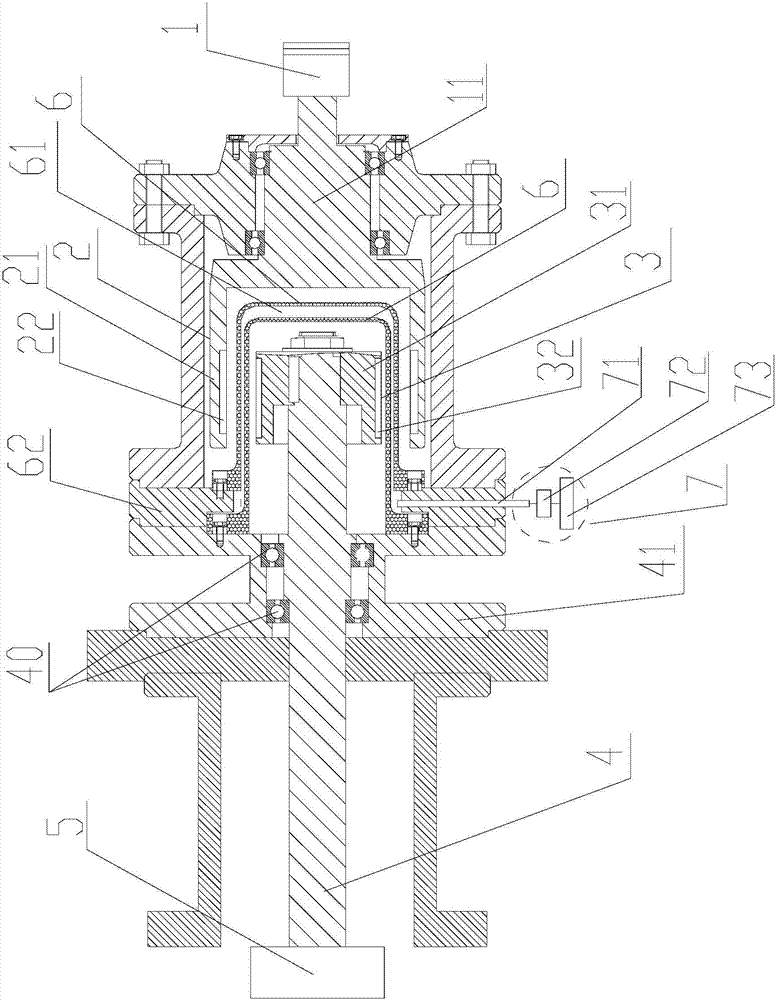

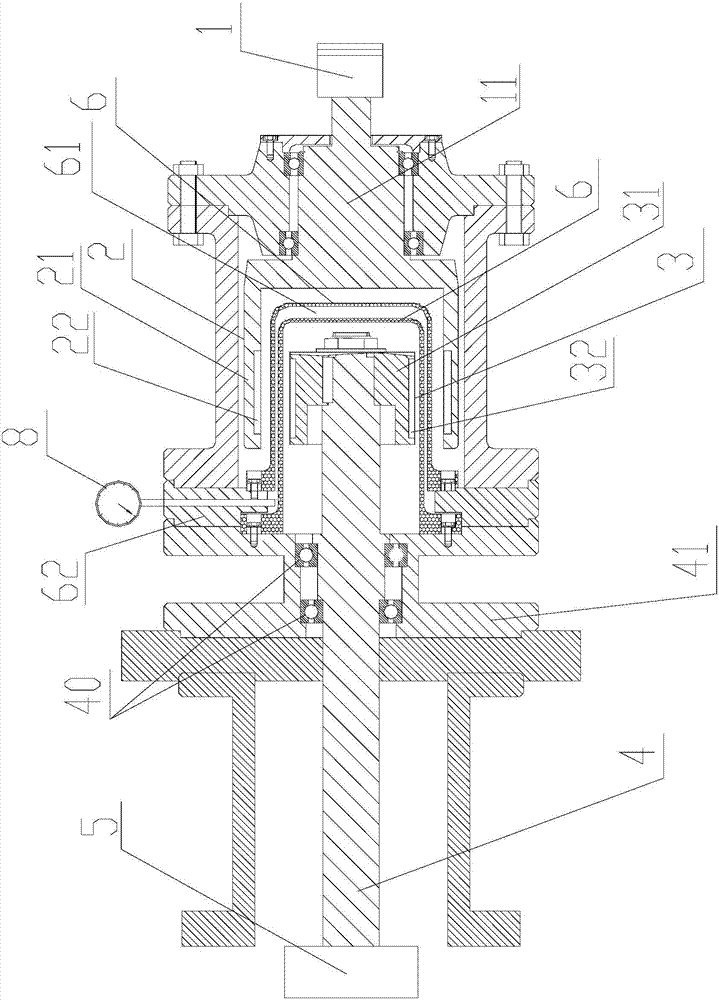

[0021] See figure 1 Embodiment one of the present invention shown, and figure 2 The second embodiment of the present invention shown is a magnetically driven submerged liquid chlorine pump, comprising an electric motor 1, an outer magnetic cylinder 2 driven by the electric motor 1, and an inner magnetic cylinder 3 magnetically coupled with the outer magnetic cylinder 2, wherein , the inner magnetic cylinder 3 is connected to the end of the output shaft 4 of the liquid chlorine pump, the front end of the output shaft 4 of the liquid chlorine pump is provided with an impeller 5, and the output shaft 4 of the liquid chlorine pump is erected on the bearing bracket 41; the inner magnetic cylinder 1 and the outer magnetic cylinder There is a multi-layer isolation sleeve 6 between 2; in the drawings of the specific embodiment 1 and the specific embodiment 2 of the present invention, the double-layer isolation sleeve is taken as an example, and it is obvious that it can be three or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com