Air duct flow measuring system

A flow measurement and intake port technology, applied in the field of intake port flow measurement systems, can solve the problems of complex flow matching and aerodynamic interference in the intake port, strong aerodynamic interference, and inability to simulate the coupling characteristics of the intake port. The effect is good, the integrity is good, and the components are easy to assemble and disassemble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further introduced below in conjunction with the accompanying drawings.

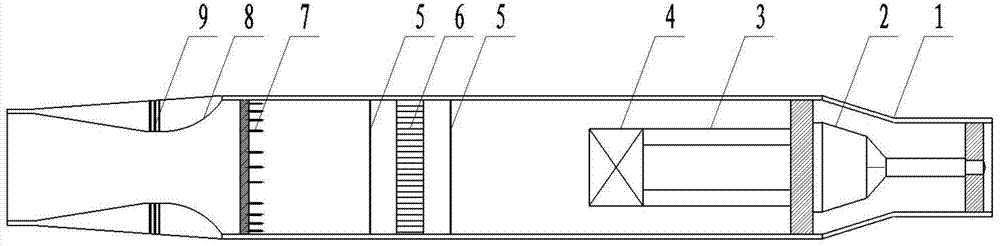

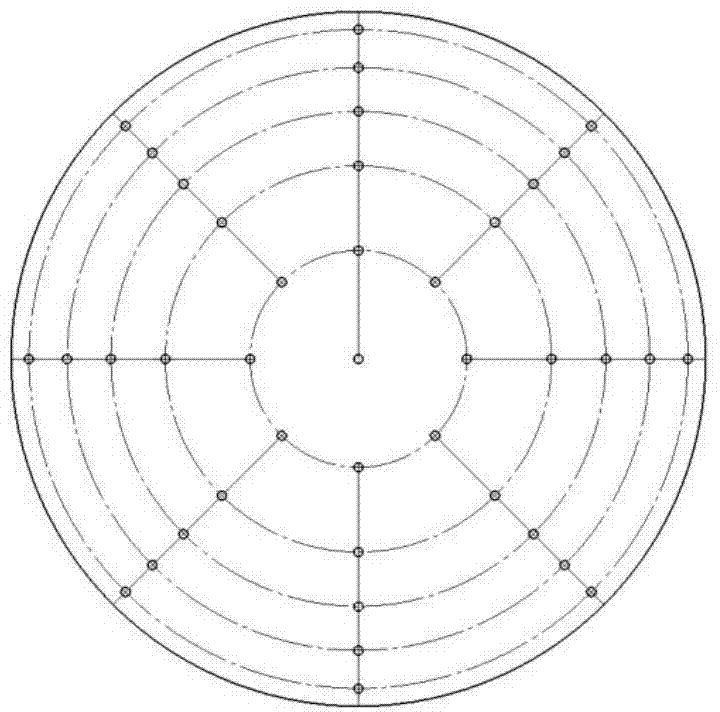

[0030] Such as figure 1 As shown, the intake port flow measurement system of the present invention includes a housing 1, a throttle cone 2, a servo motor 3, a feedback device 4, a damping net 5, a honeycomb 6, a total pressure measurement rake 7, a Laval nozzle 8 and The static pressure measuring device 9 has a cylindrical housing 1 with an interface at its front end, which can be sealed and connected to the outlet of the air inlet test model through a medium-pressure rubber hose in the laboratory. At the rear end of the interface there is a flared section for decelerating the incoming flow, followed by a straight section. The throttling cone 2 is arranged in the expansion section, and the servo motor 3 and the feedback device 4 are arranged in the straight section of the housing 1 . The throttling cone 2, the servo motor 3 and the feedback device 4 together constit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diagonal length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Total length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com