Cable apparent image defect detection device

A defect detection and image technology, applied in the field of image processing and hardware implementation of image processing, can solve the problems of limited image processing system speed, poor computer portability, poor real-time performance, etc., to achieve low cost, fast processing speed, real-time performance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

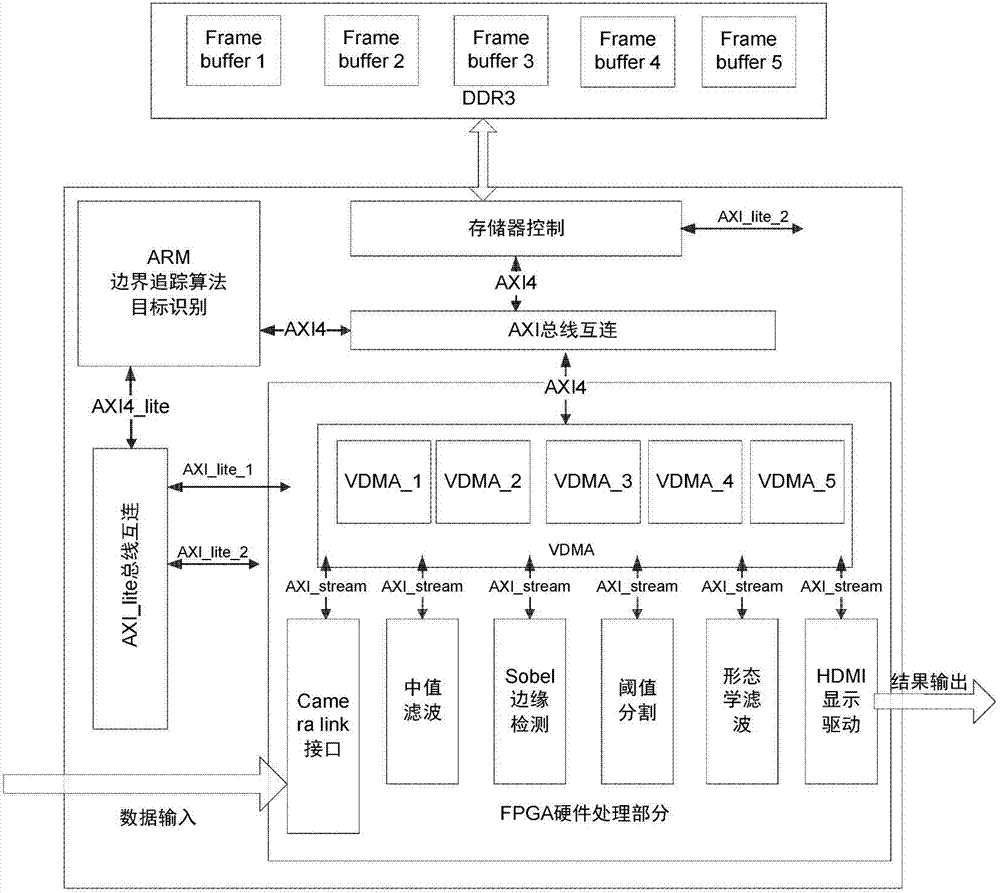

[0011] A cable apparent image defect detection device includes a zynq processing platform and an off-chip DDR3 memory; the zynq processing platform includes an ARM part, an FPGA hardware processing part and a bus interconnection part; the ARM part is a dual-core ARM Cortex- A processing system (Processing System, PS) of the A9 multi-core processor, the ARM part configures the working mode of the VDMA and the memory control module through the AXI_lite protocol, and completes the boundary tracking and target recognition algorithms in the image processing step.

[0012] The FPGA hardware processing part is implemented using programmable logic (Programmable Logic, PL) on the zynq chip, including a synchronous trigger module, a camera link interface module, a median filter module, a sobel edge detection module, a threshold segmentation module, a morphological filter module, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com