Calibration equipment and calibration method for linear array camera of high-speed rail detection system

A line scan camera and detection system technology, applied in image analysis, instruments, calculations, etc., can solve problems such as the inability to meet the standard requirements of fast railway maintenance and repair, achieve fast and accurate camera calibration, ensure accuracy requirements, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

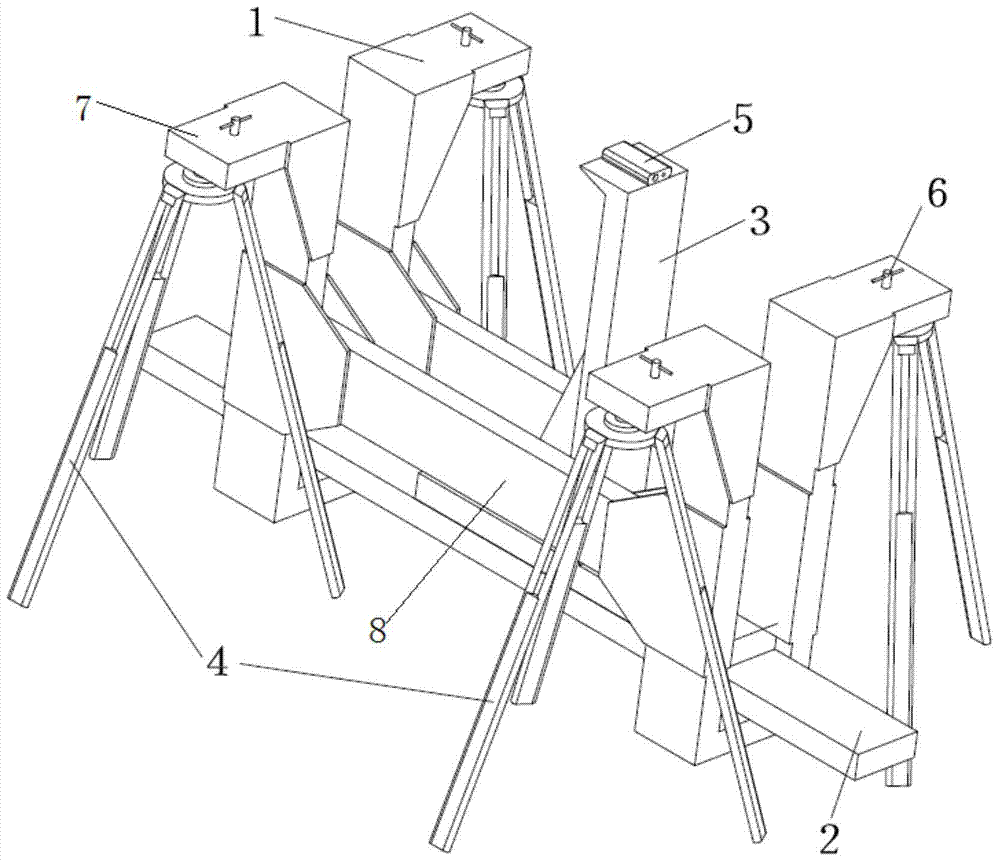

[0042] The present invention proposes a line array camera calibration device and calibration method for a high-speed rail detection system, wherein the structure of the calibration device is as follows figure 1 Shown:

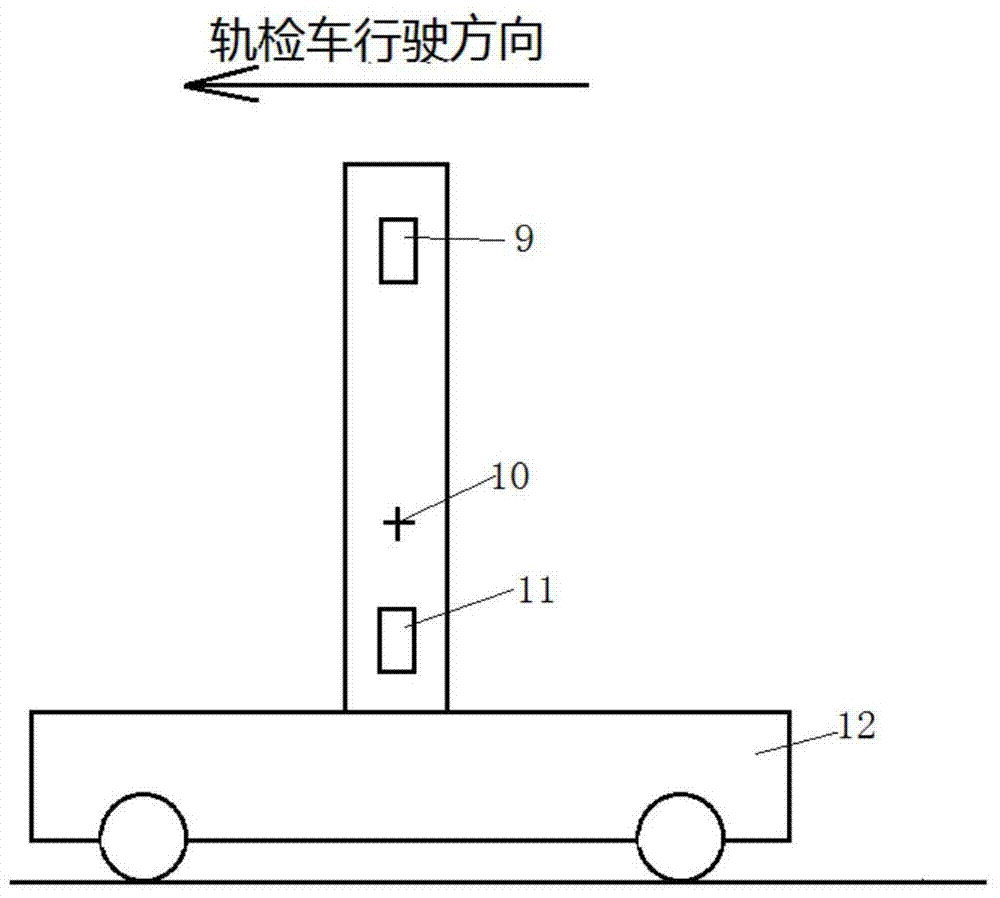

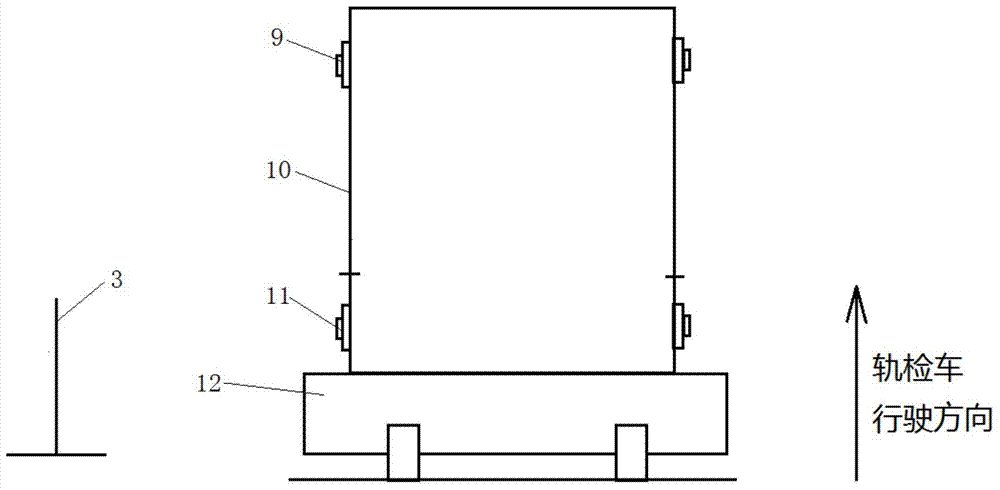

[0043] A linear array camera calibration device for a high-speed rail inspection system, the linear array camera is installed on a rail inspection car 12, a calibration plate 3 is arranged on one side of the rail inspection car 12, and a calibration tape 13 is arranged on the calibration plate 3; the calibration plate 3 can move towards or away from the rail inspection car 12, the top of the calibration plate 3 is provided with a laser rangefinder 5, and the rail inspection car 12 is provided with a positioning mark 10.

[0044] Such as figure 1 and figure 2shown. The line array cameras are distributed on both sides of the rail inspection vehicle 12, and each side is provided with a camera in the up and down direction. The calibration of the camera is acco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap