Method for measuring fresh air by evaluating internal cylinder pressure signal

A cylinder and air quality technology, applied in electrical control, machine/engine, engine control, etc., can solve problems such as the complexity of the engine control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The same or similar parts are indicated by the same reference symbols in the figures. The illustrations in the figures are schematic and not to scale.

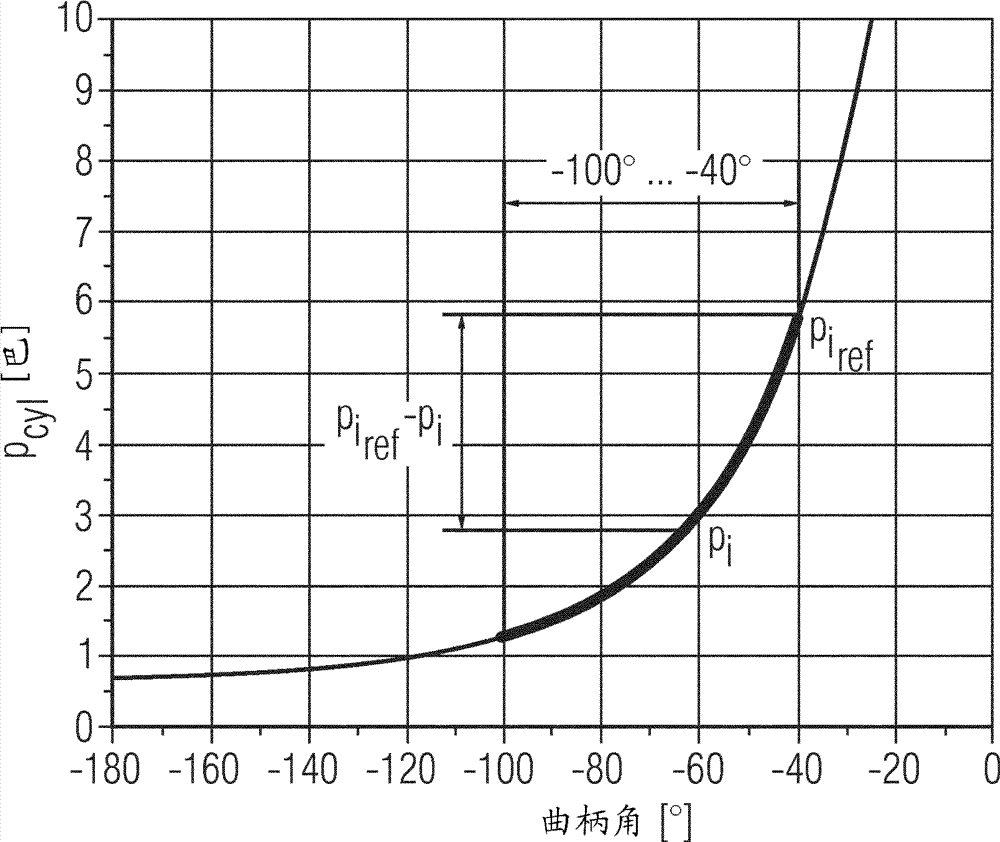

[0086] figure 1 shows the total gas mass m in the cylinder of the internal combustion engine during the compression phase Cyl pressure curve. Crank angles between -180° and 0° are indicated on the X-axis. Between -180° and 0° crank angle there is a portion of the cylinder's intake phase and compression phase. For example, up to a crank angle of 110°, a gas mixture such as, for example, air and / or fuel is drawn in, and from 110° onwards the inlet valve is closed. Subsequently, between a crank angle of 110° and a crank angle of 0°, the compression work starts, where the piston in the cylinder causes the total gas mass m in the cylinder to Cyl compression.

[0087] exist figure 1 In the example in , the first angular range for determining the crank angle in the compression phase is between approximately 100° and -40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com