Suspension method and shock-absorbing device for an automobile

A damping device and damping technology, applied in suspension, elastic suspension, vehicle components, etc., can solve the problems of weakened trim control, imperfect stiffness and damping, and difficulty in maintaining mechanical quality, and achieve the effect of favorable action and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

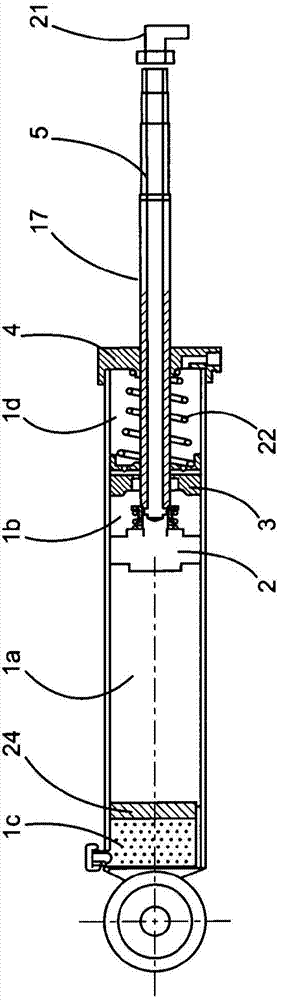

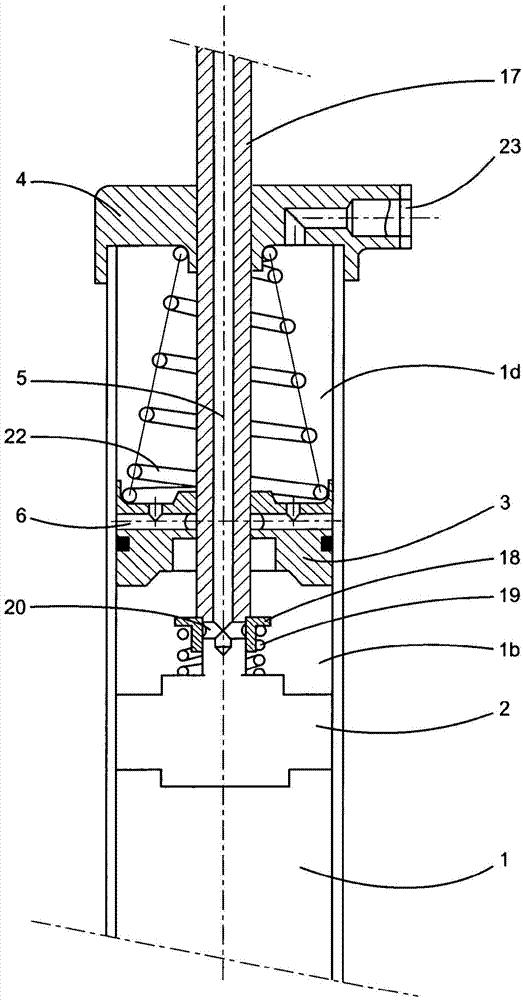

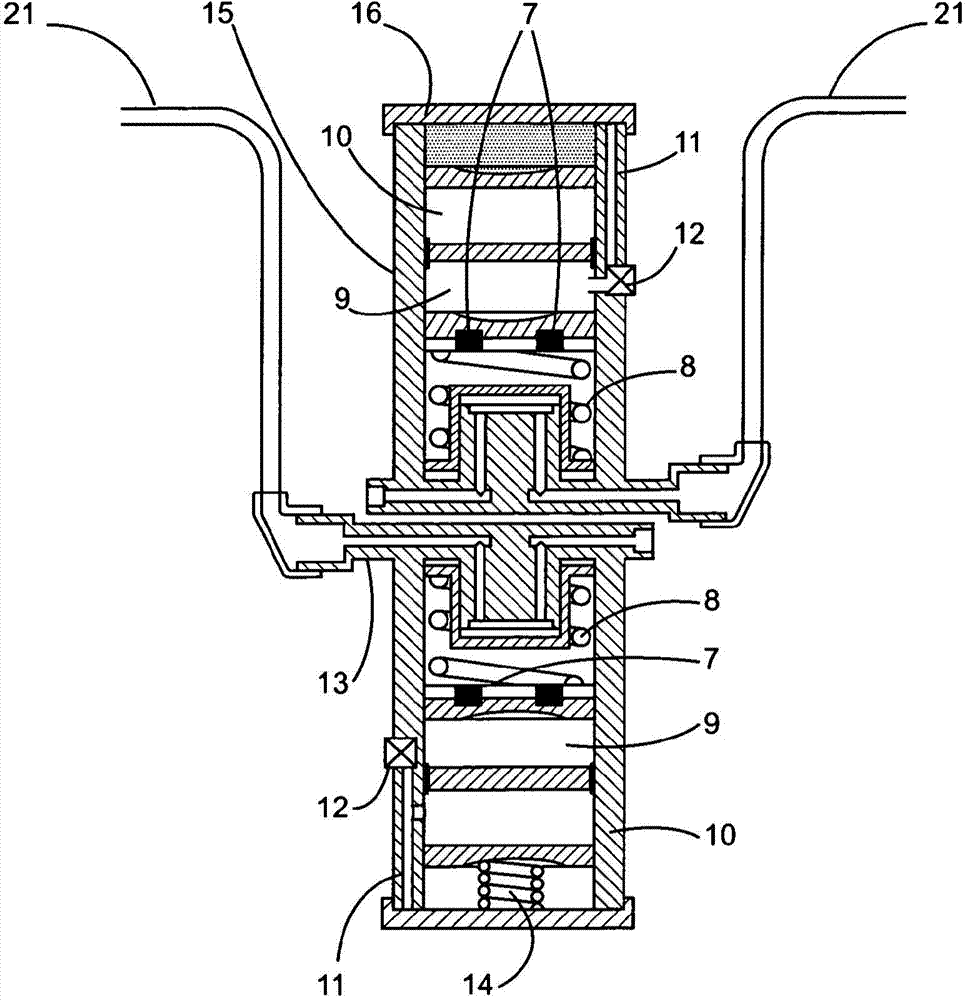

[0079] figure 1 The damping fitting 1 is shown. The damping fitting 1 is shown as an oleo-pneumatic damping device, but the invention is not limited to this damping device and can be applied to any type of damping device. The damping fitting 1 has a piston 2 which is movable inside the damping fitting 1 by dividing the interior into two chambers 1a and 1b.

[0080] The piston 2 is connected to a connecting rod 17 which extends lengthwise to and inside the damping fitting 1 and exits said interior through the longitudinal end of the fitting 1 . The longitudinal ends form the upper closure 4 of the damping fitting 1 . At the other longitudinal end of the damping fitting 1 a gas (for example nitrogen) inlet is provided to control the movable layer which puts the oil contained in the damping fitting under pressure.

[0081] For oil-pneumatic damping fittings, to ensure continuous movement of the piston 2 and connecting rod 7 fittings, the piston 2 is immersed in hydraulic fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com