Whole-process adsorption and automatic folding mechanism for full-automatic nailing machine

A technology of folding mechanism and nail box machine, which is applied in the direction of container manufacturing machinery, paper/cardboard containers, box production operations, etc. It can solve the problems of low production efficiency, high cost, and multiple labor costs, so as to improve production and processing efficiency and save The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

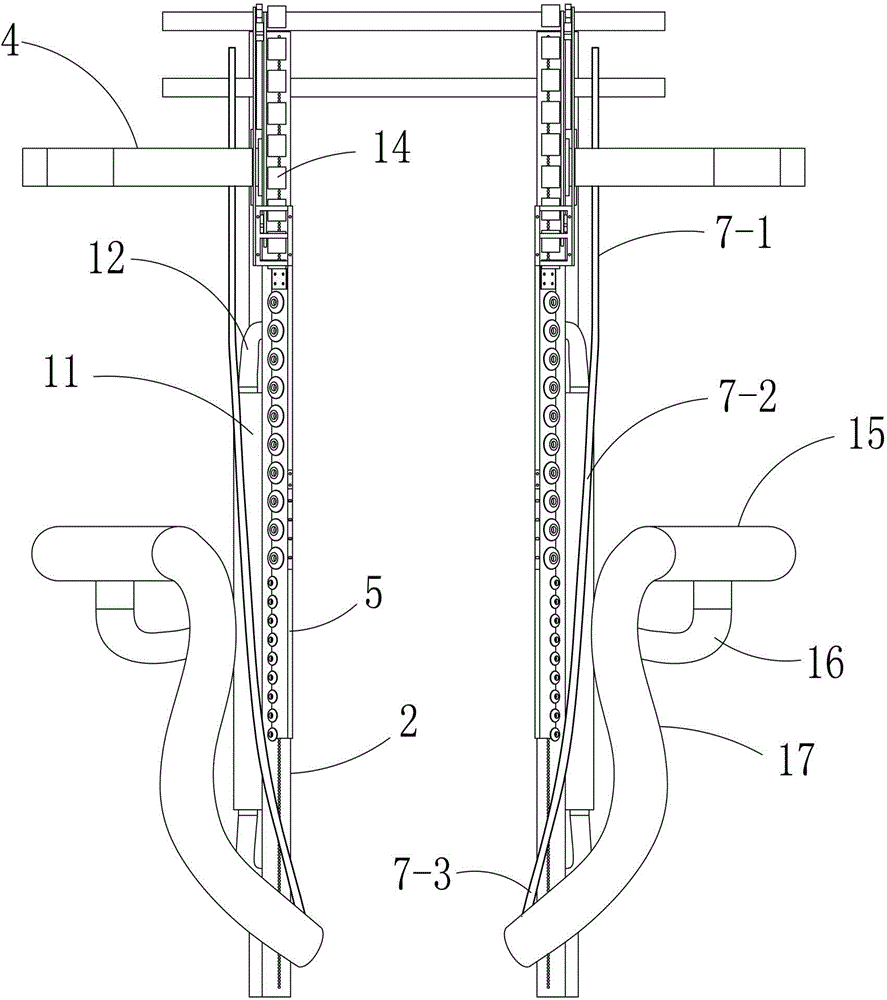

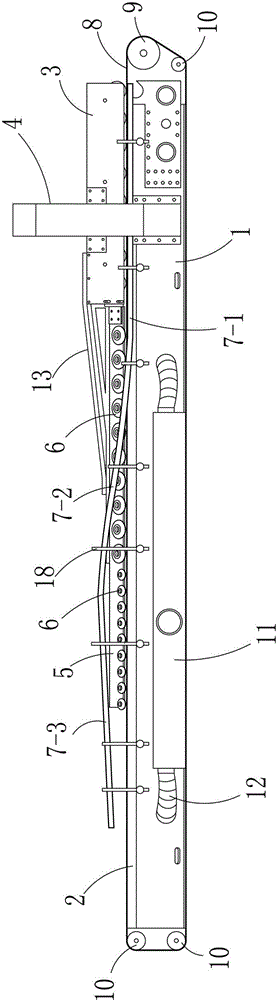

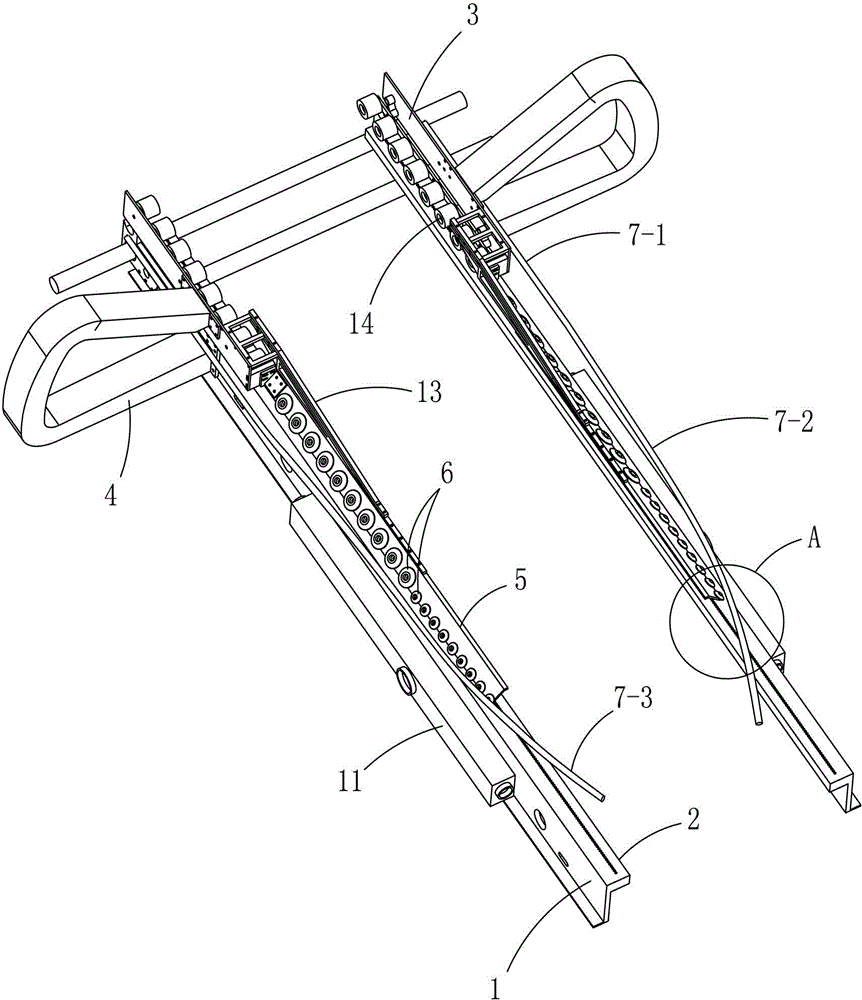

[0024] Attached below Figure 1-5 The invention is described in further detail with specific embodiments:

[0025] as attached Figure 1-5 The full-automatic nail box machine shown in the figure has an automatic folding mechanism, which is arranged between the front edge paper feeding mechanism 100 and the nail box mechanism 200, and transports the cartons output from the front edge paper feeding mechanism 100 to the nail box after being folded. The box mechanism 200 nails, which connects the leading edge paper feeding mechanism 100 and the nail box mechanism 200, and can fold according to the creasing marks of the cardboard during the feeding process.

[0026] The described sending-to-folding mechanism includes two parallel-arranged traveling booms 1, and the traveling boom 1 is erected between the leading edge paper feeding mechanism 100 and the nail box mechanism 200, and passes through the leading edge paper feeding mechanism 100 and the nail box The mechanism 200 is sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com