Brick stacking manipulator capable of automatically adapting to brick stacking position

A manipulator and self-adaptive technology, applied in the field of brick stacking manipulators, can solve the problems of not being able to adapt to the position of stacking bricks, unfavorable for the neat stacking of brick stacks, etc., and achieve the effects of small occupied space, simple structure and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

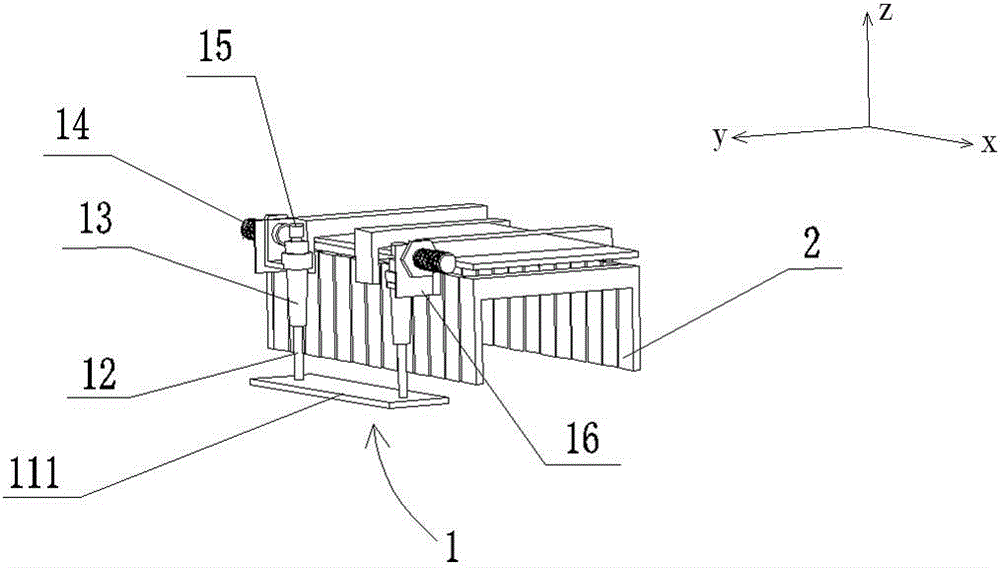

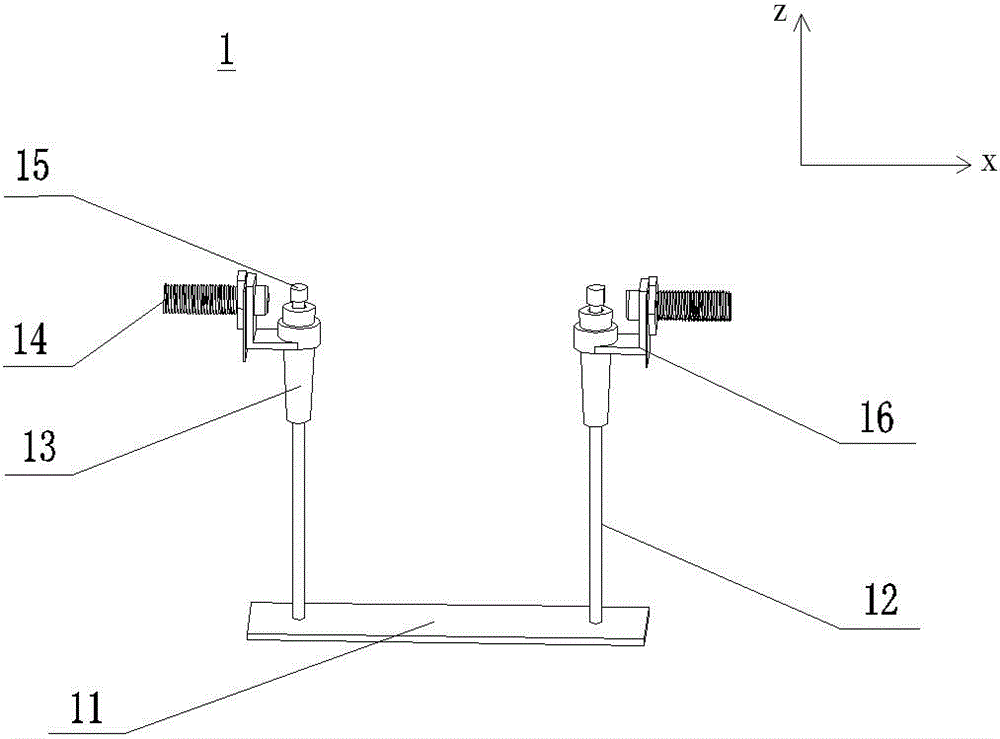

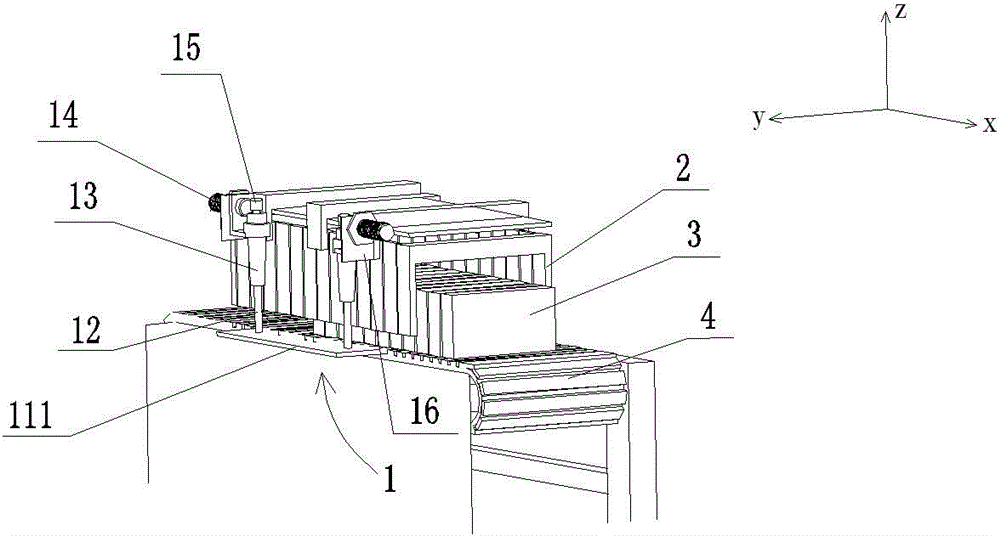

[0018] The present invention proposes a brick stacking manipulator that adapts to the position of stacking bricks, such as figure 1 As shown, the brick stacking manipulator with adaptive brick stacking position includes a brick stacking position adaptive detection mechanism 1 located outside the two side plates 2 on both sides thereof. figure 2 Yes figure 1 Schematic diagram of the self-adaptive detection mechanism for the middle stack of bricks, such as figure 2 The position adaptive detection mechanism 1 for stacking bricks includes a baffle 11 arranged along the x direction, two light bars 12 located at both ends of the baffle 11 and perpendicular to the baffle 11 along the z-axis direction, and two light bars 12 respectively located The upper part is set with two bearing rings 13 of the light rod 12 and two adaptive sensors 14 symmetrically fixed on the corresponding positions of the two bearing rings 13 along the vertical direction of the light rod 12. The adaptive sen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap