Fully automatic car wash sewage treatment equipment

A technology for car washing sewage and treatment equipment, applied in the field of car washing, can solve the problems of waste of water resources for car washing and high cost of sewage treatment, and achieve the effects of high water utilization rate, low water treatment cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

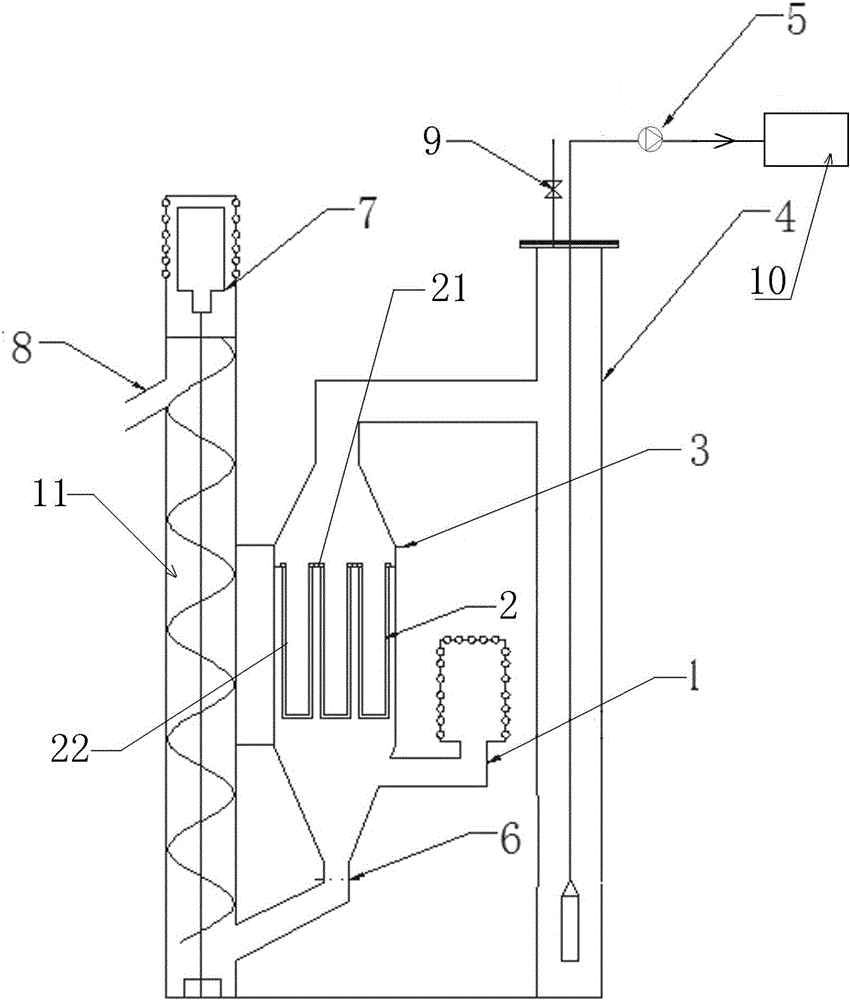

[0011] Embodiment 1: A kind of automatic car washing sewage treatment equipment, see figure 1 , including a negative pressure tank 3, a siphon well 4 and a sludge lifter 7 arranged in the sewage tank, the negative pressure tank 3 is equipped with a purification element 2, a sewage inlet 1 is set on the side of the lower part of the negative pressure tank, and a sewage outlet 6 is set at the bottom, The height of the sewage outlet 6 is lower than the sewage inlet 1, so that after the sewage enters the negative pressure tank, the sludge can first fall naturally by its own gravity, and is connected with the sewage outlet. At the top of the mud lifting pipeline 11, a sludge discharge outlet 8 is arranged on the side of the top of the sludge lifting pipeline, and the upper part of the negative pressure tank is provided with a clean water outlet. A water pump 5 is installed, and the outlet of the water pump 5 is connected to the recovery tank 10. A water replenishment port is also a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com