A kind of anti-slip wear-resistant inkjet printing coating coating

An inkjet printing and coating technology, applied in the field of coatings, can solve the problems of poor skid resistance, low wear resistance coefficient, and many processes, and achieve the effect of enhancing the attractiveness of the picture, good friction resistance, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

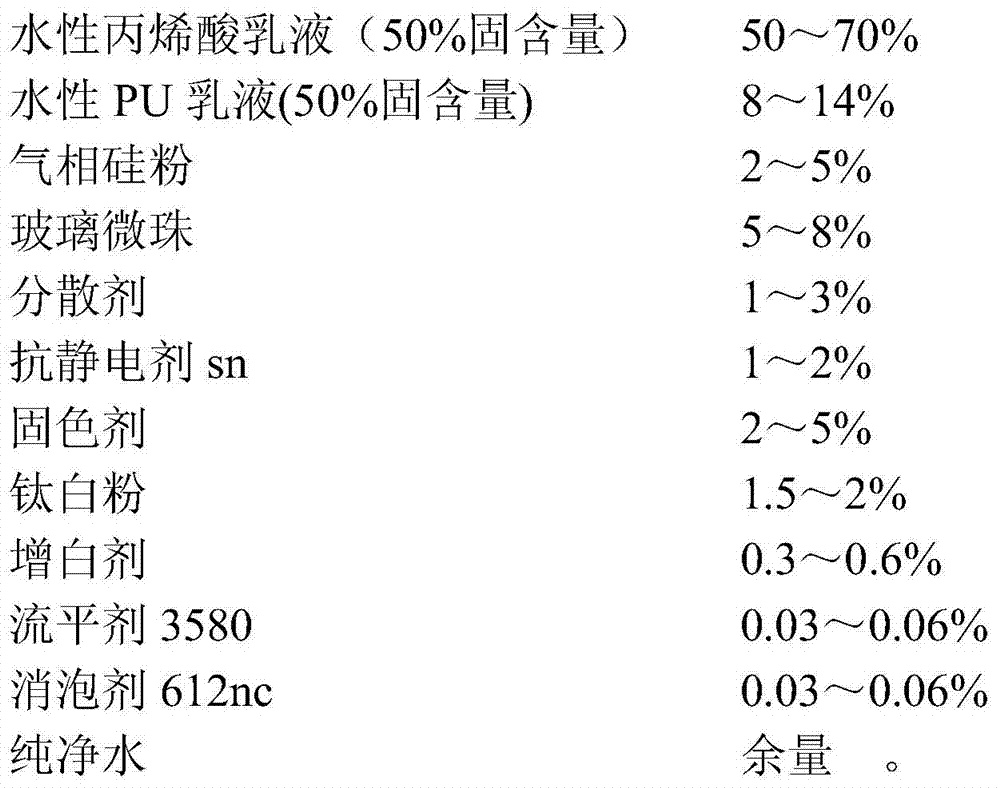

[0017] A kind of antiskid wear-resisting ink-jet printing coating coating, comprises following component, by weight percentage:

[0018]

[0019]

[0020] The processing process of the above-mentioned coating: after each component is weighed, add water-based acrylic emulsion (50% solid content) and water-based PU emulsion (50% solid content) with a high-speed mixer, stir evenly, and then add other components in turn.

Embodiment 2

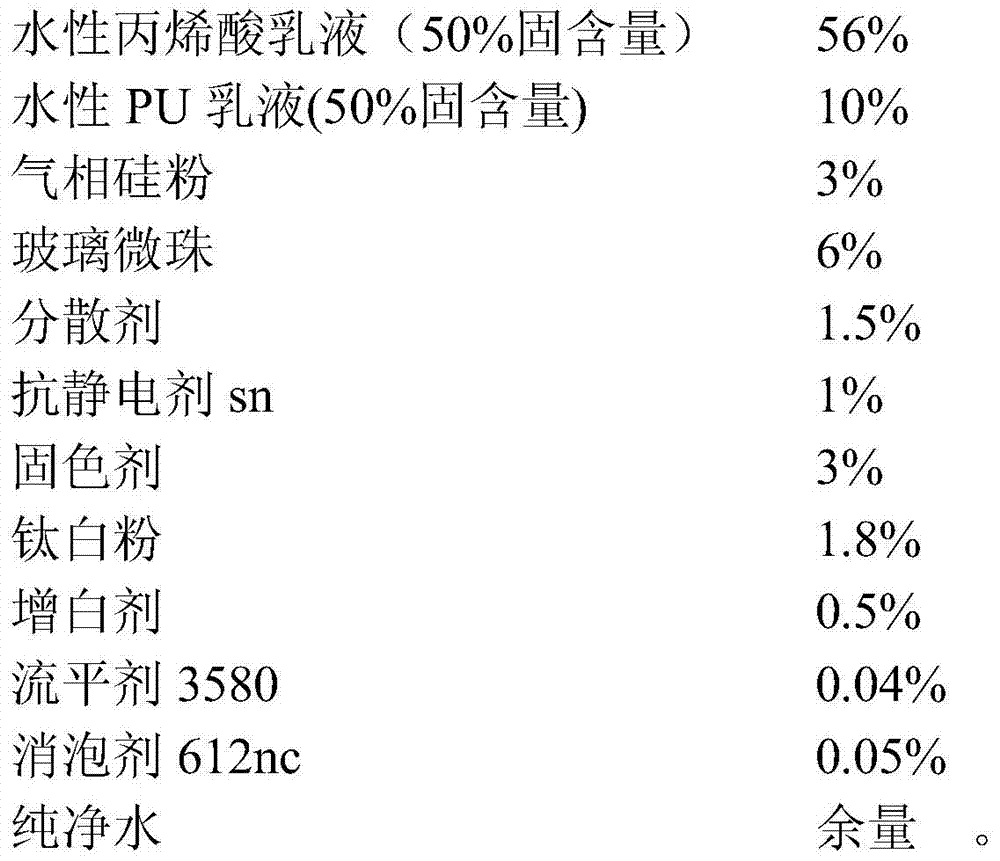

[0022] A kind of antiskid wear-resisting ink-jet printing coating coating, comprises following component, by weight percentage:

[0023]

[0024] The processing process adopts the process method of embodiment 1 to produce.

Embodiment 3

[0026] A kind of antiskid wear-resisting ink-jet printing coating coating, comprises following component, by weight percentage:

[0027]

[0028]

[0029] The processing process adopts the process method of embodiment 1 to produce.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com