A climbing ladder with double pipes and protective cages for steel pipe poles

A technology of steel pipe rods and pipe belts, which is applied in the direction of ladders, buildings, building structures, etc., can solve the problems of climbing ladders without safety cages, reaching 60 meters or even higher, and potential safety hazards, so as to increase the climbing space, The effect of protecting personal safety and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

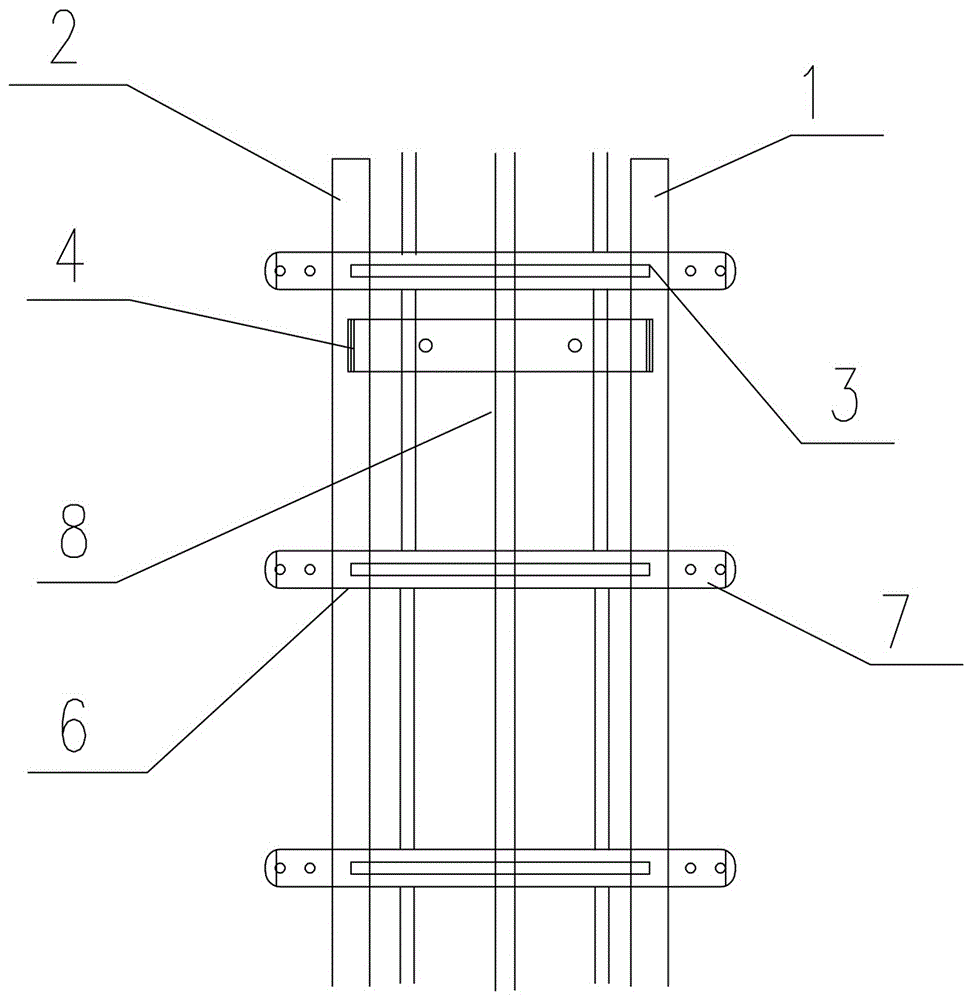

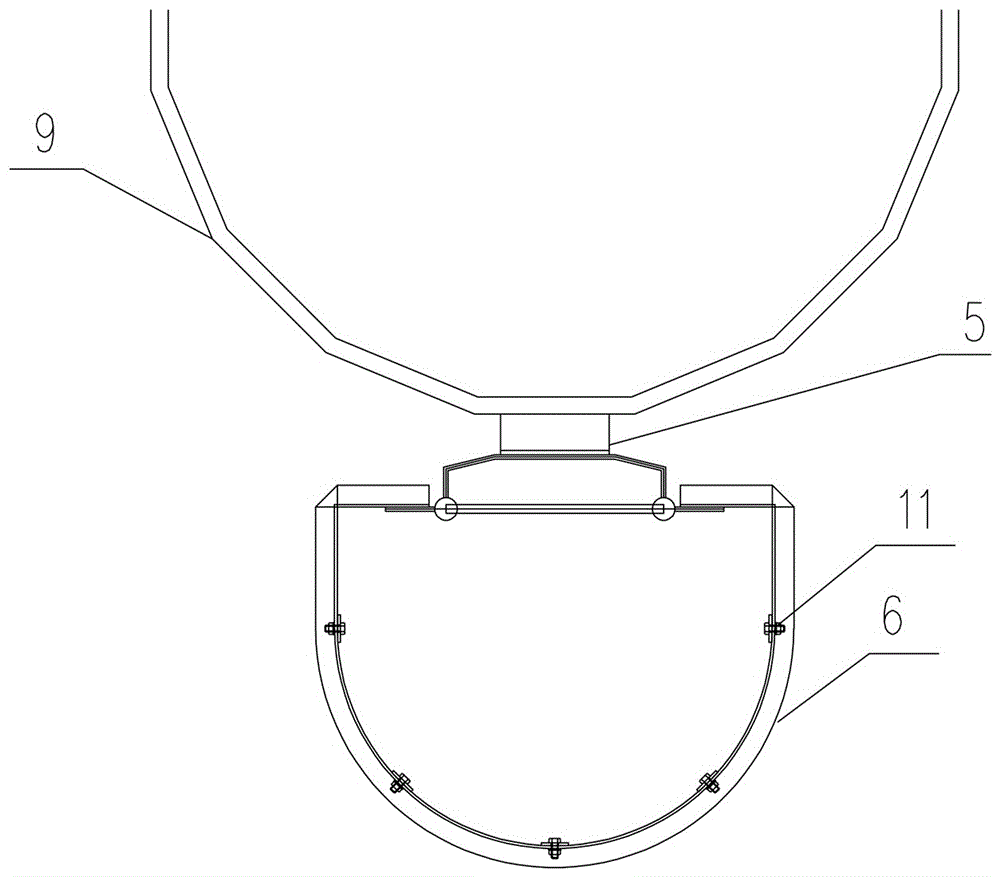

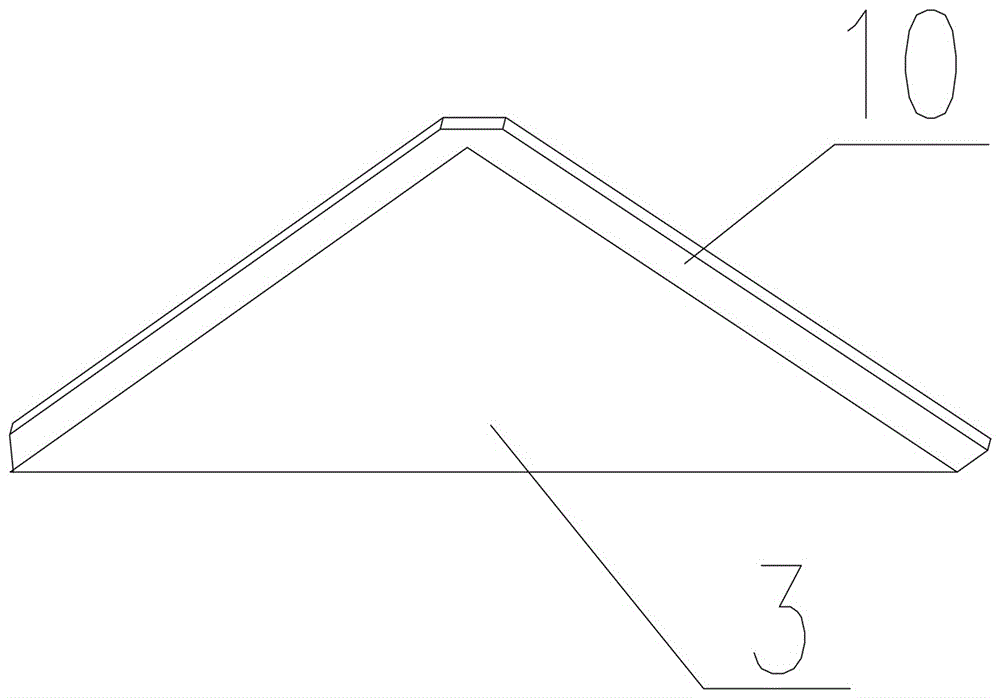

[0024] Such as Figure 1 to Figure 3 As shown, the steel pipe pole uses a double-pipe ladder with a protective cage, including a climbing structure and a protective body. The ladder includes a steel pipe 1 and a steel pipe 2. The steel pipe is provided with a climbing horizontal brace round steel 3 and a grooved climbing fixed iron piece 4. Groove type climbing fixed iron piece 4 is provided with connecting angle steel 5, and the length of steel pipe 1 and steel pipe 2 is 2 meters, and the two ends of climbing cross brace round steel 3, groove type climbing fixed iron piece 4 and connecting angle steel 5 are respectively connected with The steel pipe 1 and the steel pipe 2 are connected by welding, and the cross-section of the climbing cross brace round steel 3 is triangular, the bottom edge is parallel to the horizontal plane, and the two hypotenuses of the triangle are provided with rubber insulating material 10, and the angle steel 5 is connected with the groove-shaped climb...

Embodiment 2

[0027] The protective body comprises a semicircular retainer 6, a protective body fixing iron piece 7 and a vertical plaque steel 8 of the protective body support part, and the vertical plaque steel 8 of the protective body support part is arranged in sections, that is, one or A plurality of vertical plaque steel 8, the vertical plaque steel 8 is connected with the fixing hole 11 through bolts, and the vertical plaque steel 8 is connected with the fixing hole 11 so that the adjacent retaining ring 6 is fixed by vertical bolts. This design can flexibly adjust the vertical plaque steel between the cages distribution density, and more convenient disassembly and assembly.

[0028] In the above two embodiments, cage ladders of different lengths can be installed for steel pipe poles of different heights during actual operation, and a gap of 100 mm is reserved at the junction of the ladder sections when assembling ladders of different specifications, so that the ladders can form stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com