Method and device for controlling fan rotating speed of electronic equipment

A technology of fan speed and electronic equipment, applied in non-electric variable control, pump control, temperature control and other directions, can solve problems such as reduced heat dissipation efficiency, high noise, oscillation, etc., to ensure stable operation and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

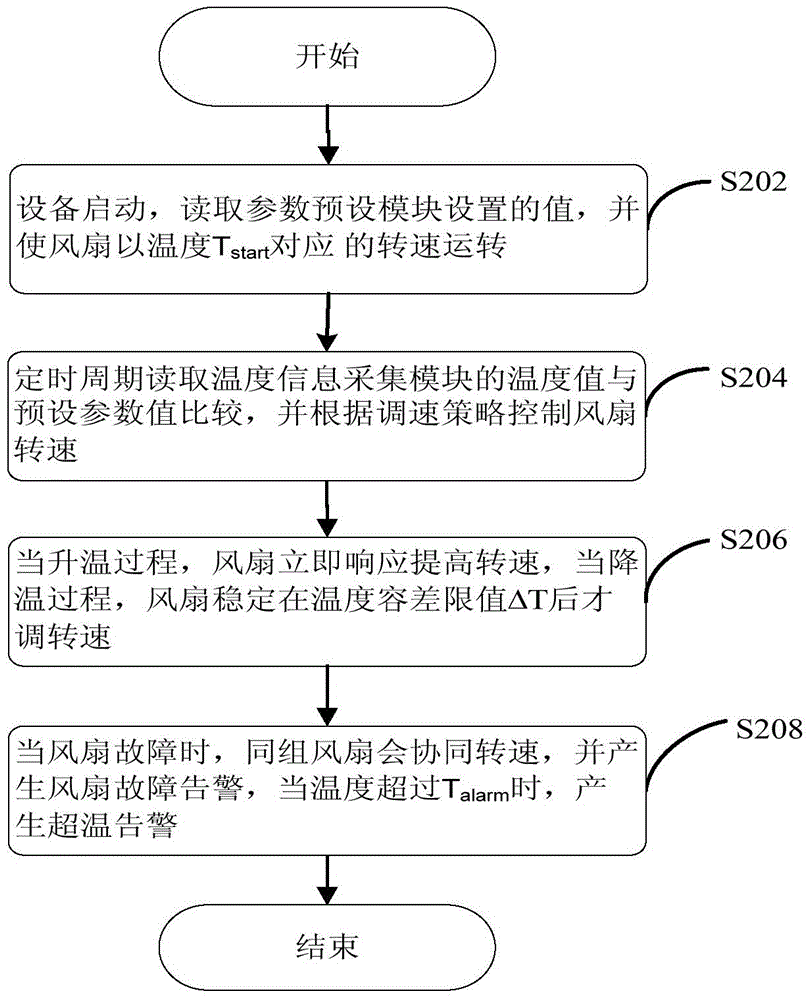

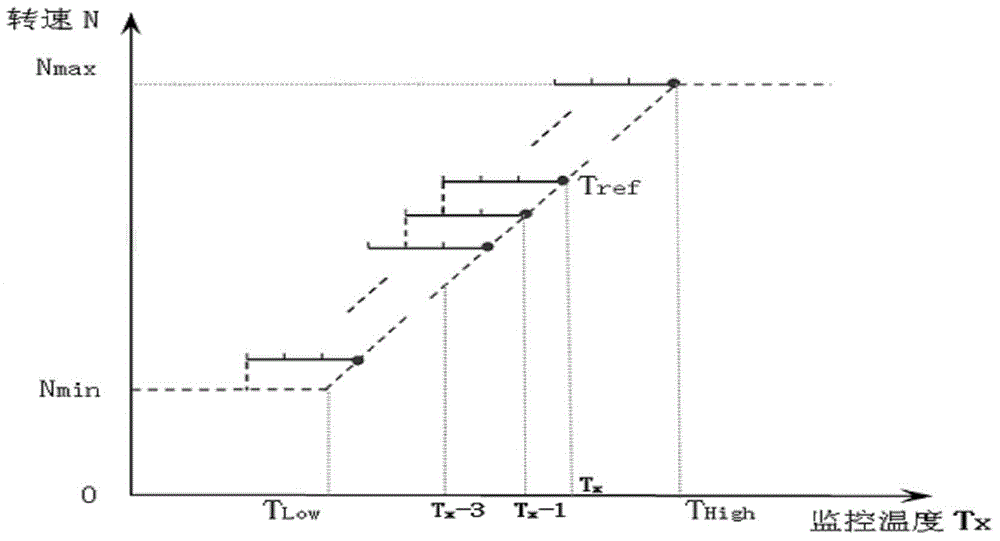

[0030] In order to achieve the following purposes: when using adjustable speed fans for heat dissipation and cooling, it can prevent the fan speed from oscillating, and reduce system noise and power consumption. , can be switched flexibly to control the device within a constant temperature set by the user through the fan speed. The following solutions are provided, as follows:

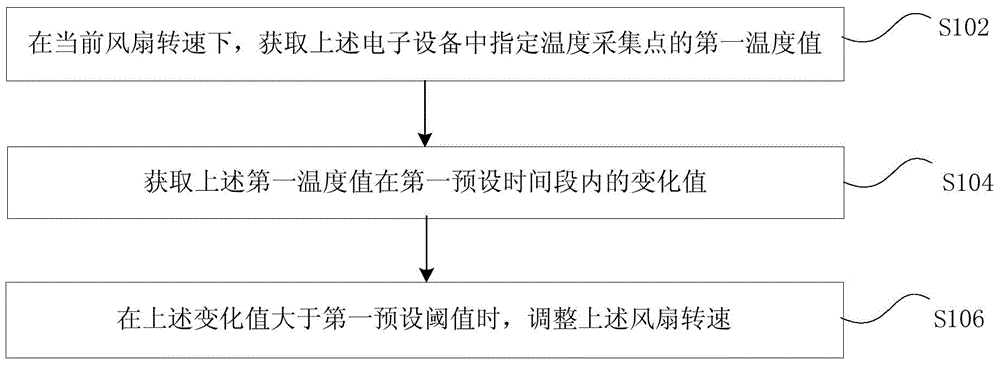

[0031] figure 1 It is a flow chart of a method for controlling fan speed in an electronic device according to an embodiment of the present invention. Such as figure 1 As shown, the method includes: step S102 to step S106,

[0032] Step S102, at the current fan speed, obtain the first temperature value of the specified te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com