Magnetostrictive drive active and passive integrated multi-degree-of-freedom precision vibration isolation device

A magnetostrictive, active-passive technology, applied in non-rotational vibration suppression and other directions, which can solve the problems of limited output stroke of magnetostrictive drives, inability to meet vibration isolation requirements, and high friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

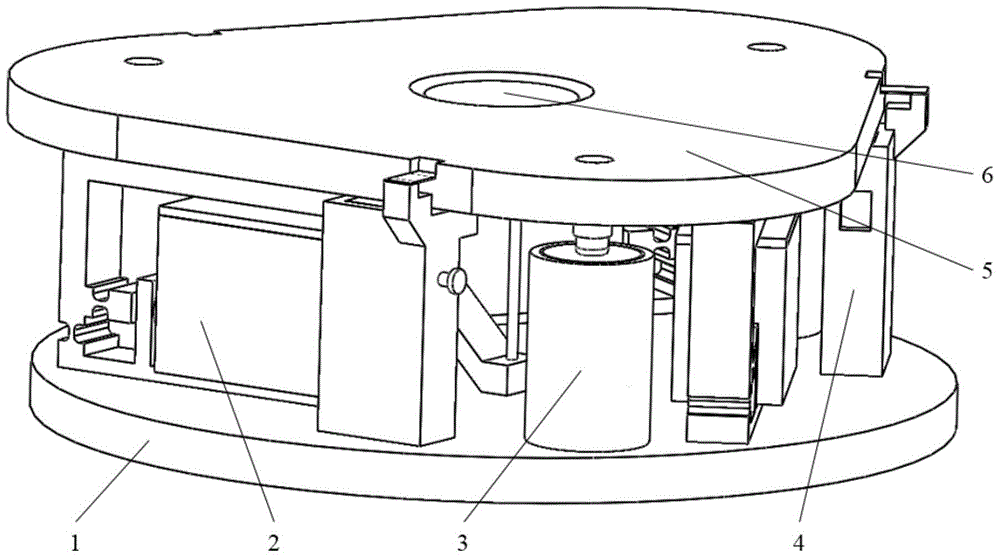

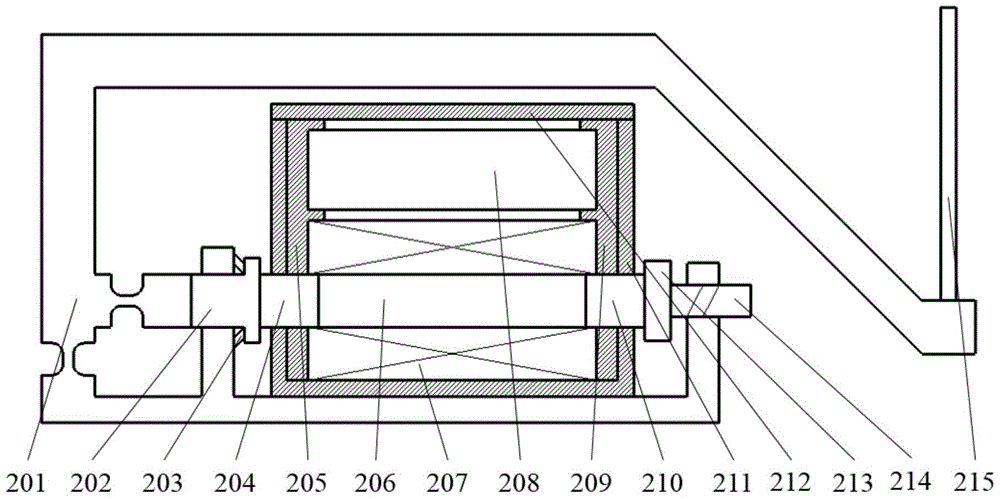

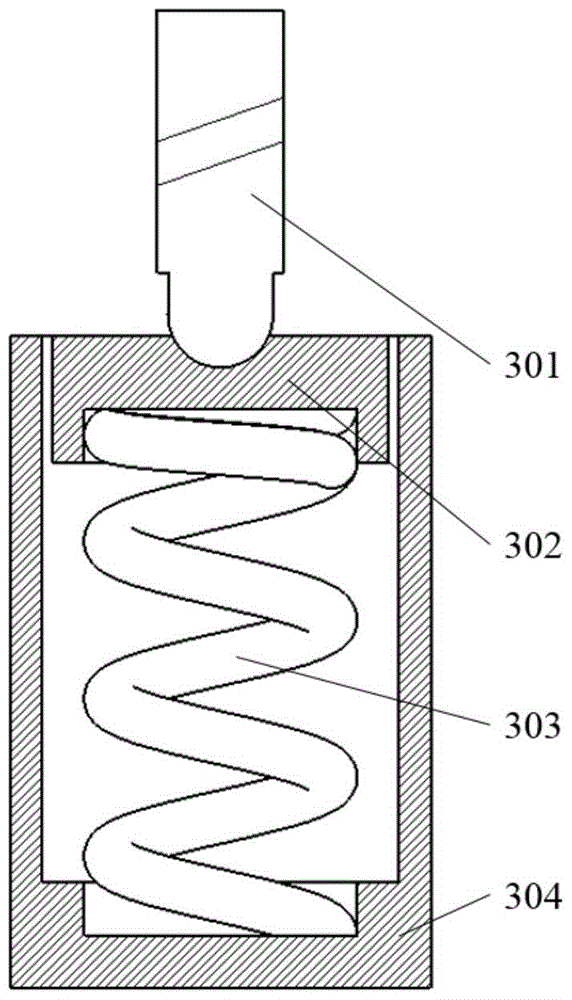

[0072] This embodiment provides a magnetostrictive active and passive integrated three-degree-of-freedom precision vibration isolation device, including an upper platform, a drive amplifier unit, a passive vibration isolation unit, a locking and limiting device, a lower platform and a vibration sensor. Among them, there are multiple driving amplification units, passive vibration isolation units and locking and limiting devices, which are respectively fixed between the upper platform and the lower platform.

[0073] Further, the lower platform is a circular plate (but not limited to a circular shape), which is used as a base of the vibration isolation device. The upper platform is a rounded triangular plate (but not limited to a rounded triangle), and the upper platform has a rectangular slot corresponding to the position of each locking limit device, and a rectangular slot corresponding to the position of each passive vibration isolation unit. Threaded hole. The vibration sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com