Trenchless pipeline traversing method integrating drilling and propping

A non-excavation, pipeline technology, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of poor adaptability, increased working time, and easy deviation of pipe jacking, etc. To achieve the effect of reliable traction and guiding performance and small annular space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

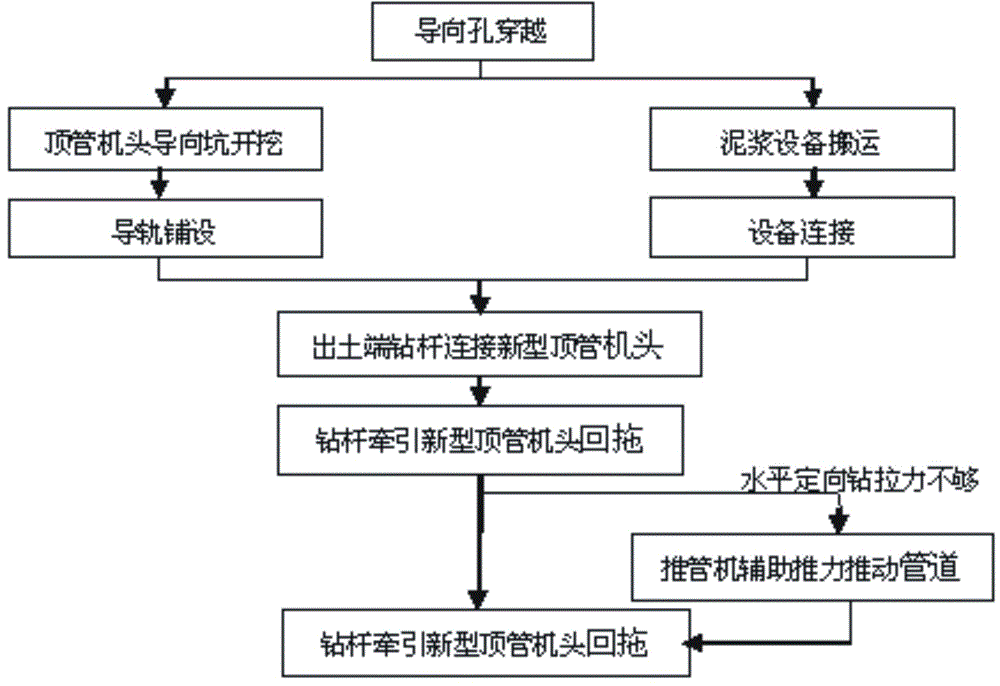

[0039] Such as figure 1 As shown, this embodiment provides a method for crossing a trenchless roof combined with a pipeline, which includes the following steps:

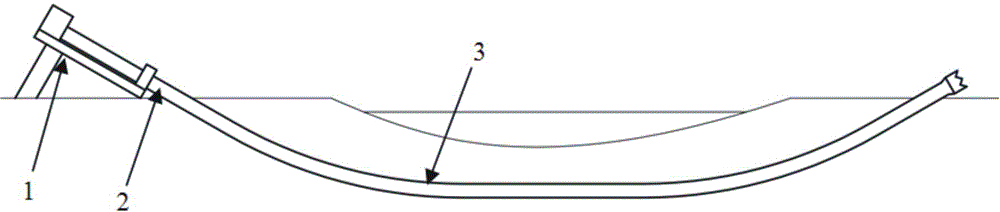

[0040] S1, such as figure 2 As shown, the horizontal directional drilling machine 1 carries out the pilot hole crossing construction to determine the pipeline trajectory. The pilot hole construction is similar to the horizontal directional drilling pilot hole construction, that is, the spatial position of the drill bit is determined by using a portable surface navigator or an artificial magnetic field.

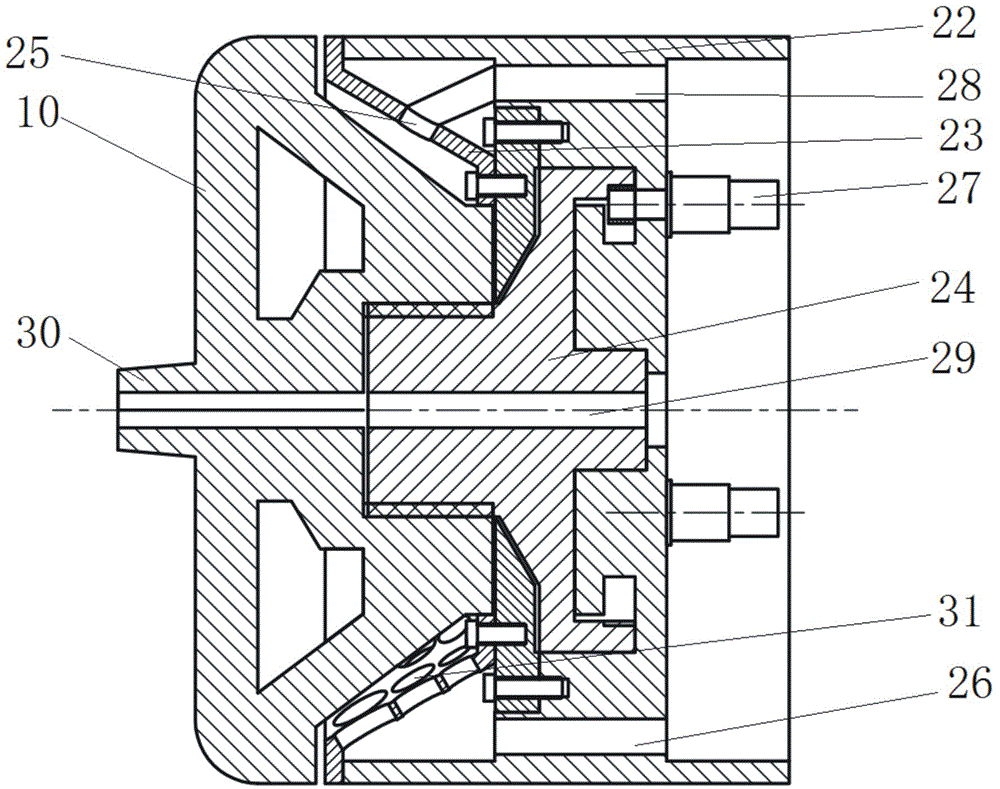

[0041] S2. Provide pipe jacking head, such as image 3 , 4 As shown, the pipe jacking head includes a cylindrical casing 22, and a cutter head 10 is arranged at the front end of the casing 22, and the cutter head 10 is driven by a hydraulic power system arranged in the casing. A drill pipe joint 10 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com