Pulverized coal accumulation prevention fixing shrinkage cavity device with horizontally-arranged primary air pipes for boiler coal pulverizing system

A pulverizing system and fixed shrinkage cavity technology, which is applied in the direction of combustion air/fuel supply, block/powder supply/distribution, combustion method, etc. It can solve delay, large average deviation of air volume distribution between pipelines, complex adjustment, etc. problem, achieve the effect of uniform speed and avoid the risk of smoldering explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] detailed description: Below in conjunction with accompanying drawing, the present invention will be further described:

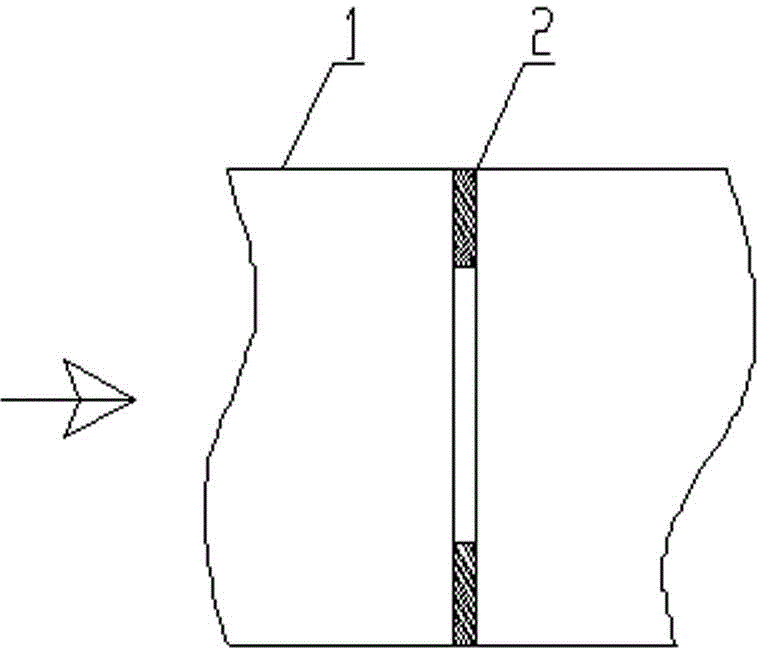

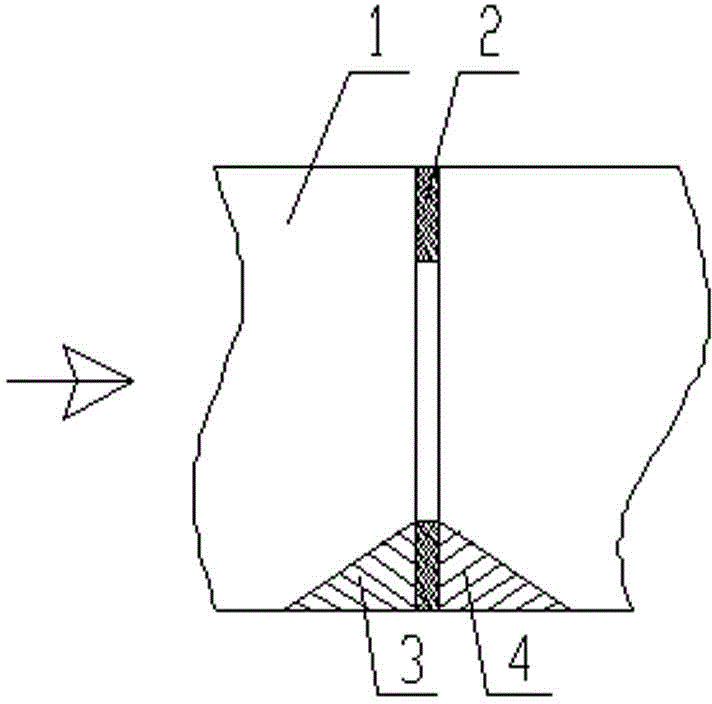

[0024] Such as figure 1 As shown, the present invention provides a non-powder-accumulating fixed shrinkage cavity device with a horizontally arranged primary air duct of a boiler pulverizing system. The device includes a horizontally installed primary pulverized coal air duct 1 and a fixed The shrinkage cavity 2 is provided with slope-shaped anti-powder accumulation devices 3 on both sides of the lower end of the fixed shrinkage cavity 2 that gradually slope downward to both sides. The unique anti-powder accumulation device 3 on the slope realizes the purpose of avoiding powder accumulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com