Efficient energy-saving multi-stage heat and humidity treatment air conditioning device and treatment method thereof

A technology for heat-moisture treatment and air-conditioning device, which is applied in the field of high-efficiency and energy-saving multi-stage heat-moisture treatment air-conditioning device and its treatment field, can solve the problems of high energy consumption, waste of resources, pollute the environment, etc. The effect of wasting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are further described below in conjunction with the drawings.

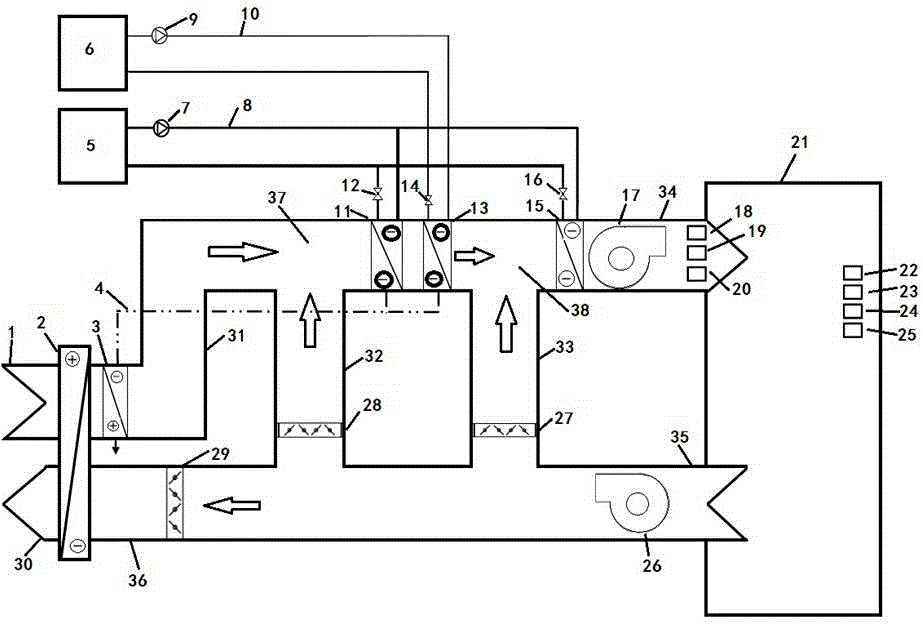

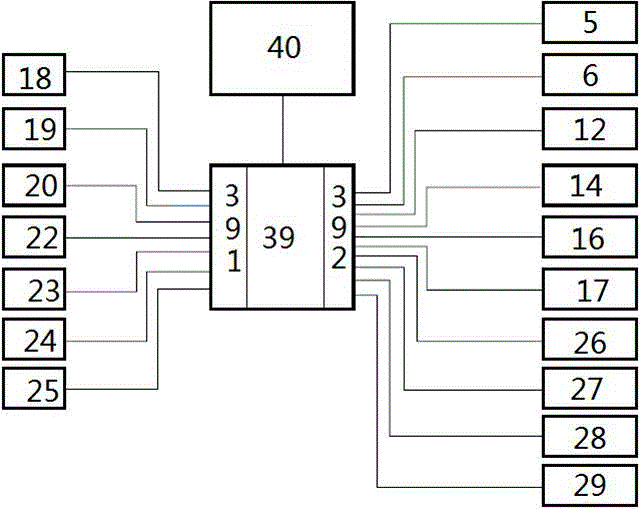

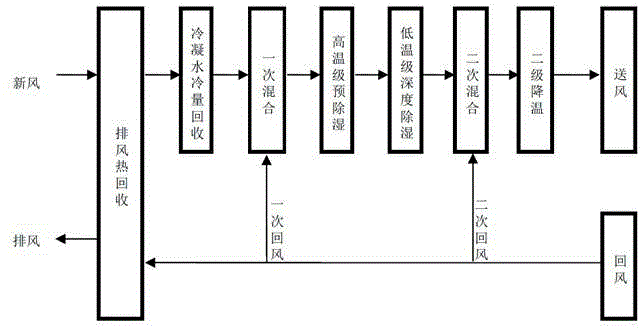

[0034] See attached figure 1 And attached figure 2 As shown, a high-efficiency and energy-saving multi-stage heat and moisture treatment air conditioner includes a refrigeration cycle component, an air circulation component, and an air heat and moisture treatment component.

[0035] The refrigeration cycle components include high-temperature refrigeration unit 5, low-temperature refrigeration unit 6, high-temperature refrigerant transfer pump 7, high-temperature refrigerant circulation pipeline 8, low-temperature refrigerant transfer pump 9, low-temperature refrigerant circulation pipeline 10, high-temperature refrigerant -Stage primary cooling and dehumidifying refrigerant supply automatic regulating valve 12, low-temperature stage secondary cooling and dehumidifying refrigerant supply automatic regulating valve 14 and high-temperature stage cooling refrigerant supply au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com