Water turbine type splashing device

A technology of splash device and water turbine, which is applied in the direction of water shower coolers, direct contact heat exchangers, lighting and heating equipment, etc. Splash impeller speed and other issues, to avoid a large drop in hydraulic power, improve the effect of water distribution, and improve the effect of cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

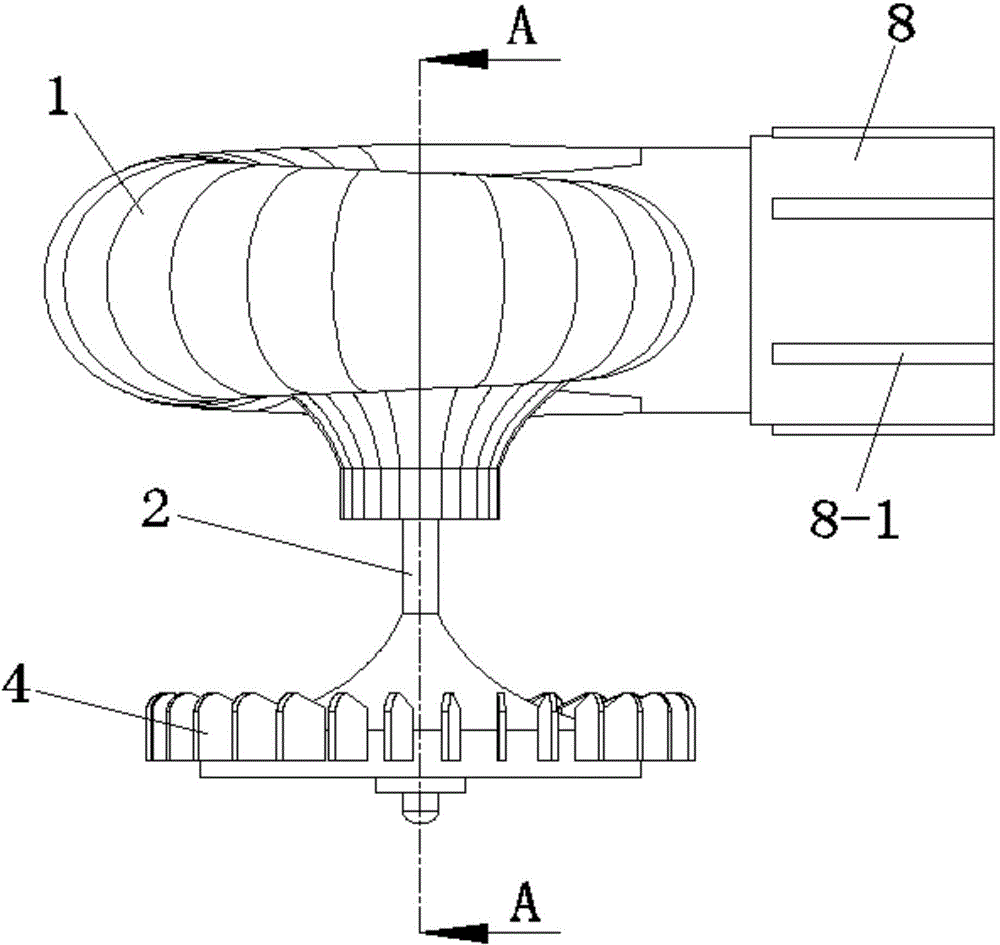

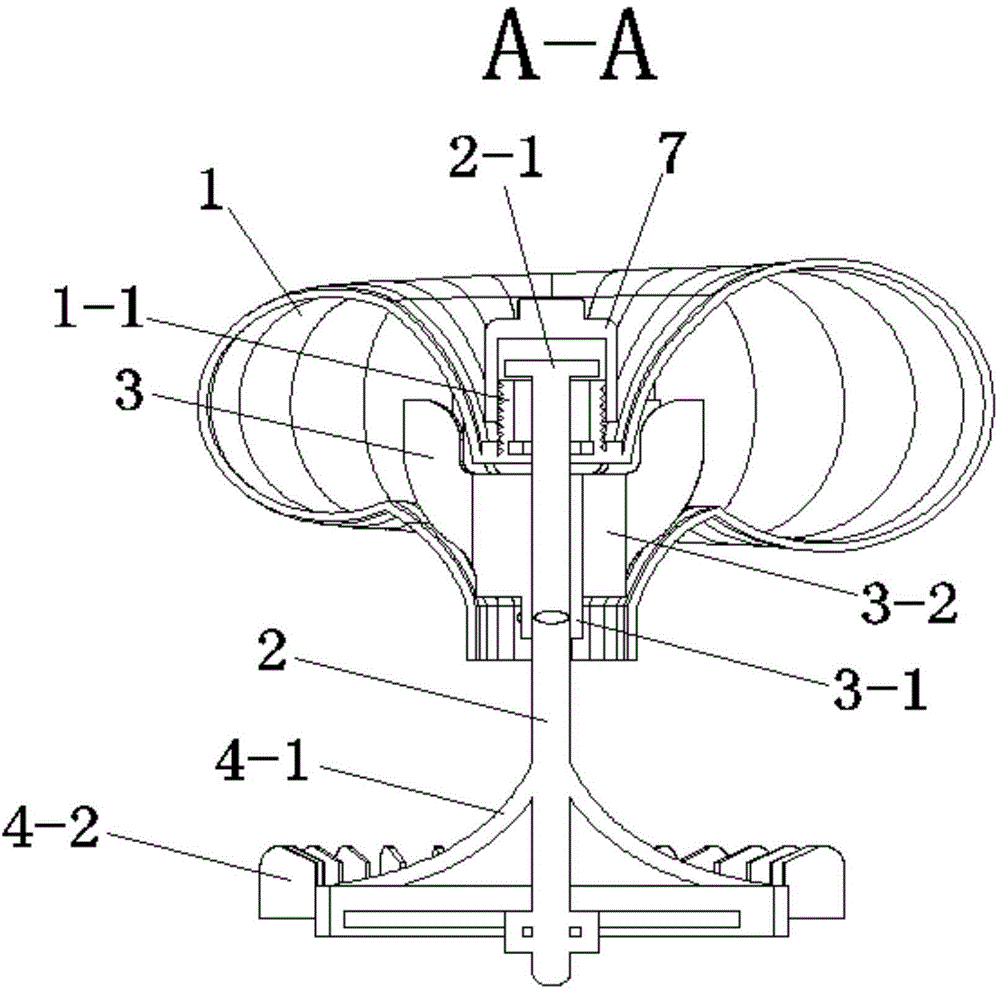

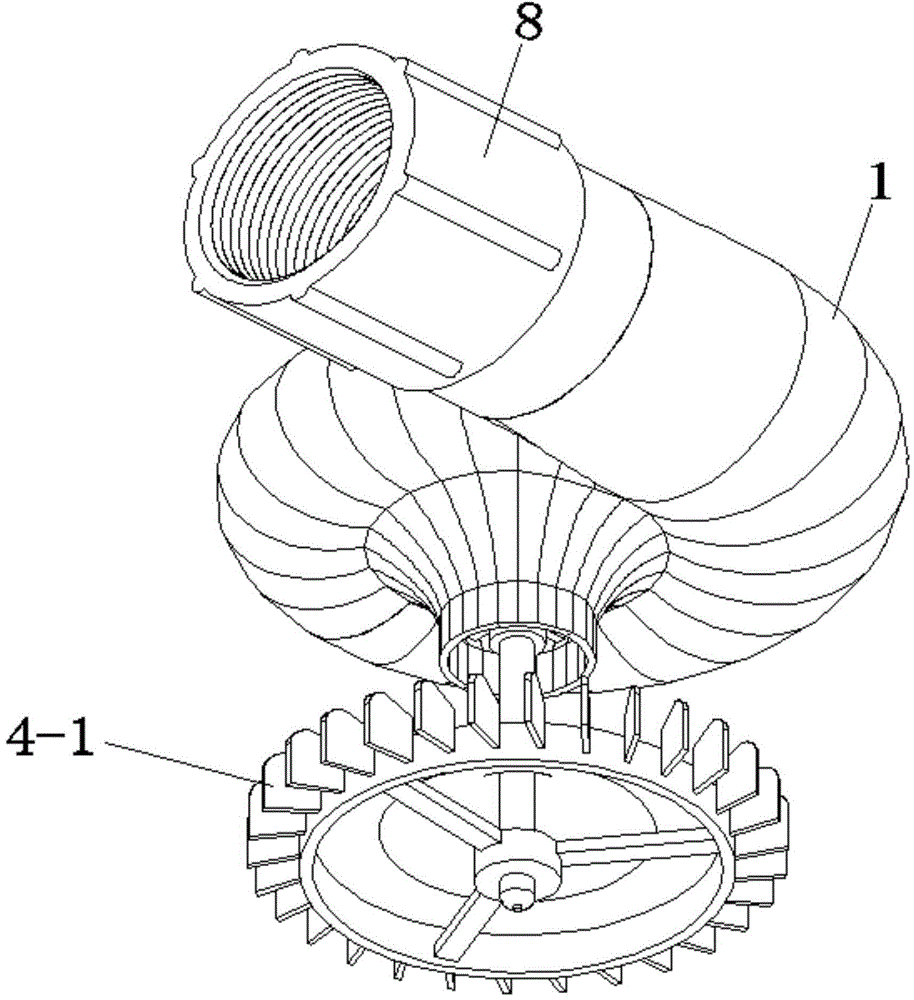

[0044] See Figure 1 to Figure 4 , the water turbine type splash device of the present embodiment can be made of any material, including volute 1, main shaft 2, hydrocyclone impeller 3, split splash impeller 4, bearing 5, rubber washer 6, pipe cap 7, connecting nut 8 and flow controller9.

[0045] The side and the bottom of the volute 1 are respectively provided with a water inlet and a water outlet. The flow controller 9 is installed at the water inlet of the volute 1 through the connecting nut 8 . A reinforcing rib 8-1 is provided on the outer periphery of the connecting nut 8. The flow controller 9 is a conical pipe. The flow channel in the volute 1 is in the shape of an equiangular spiral with a wrap angle of 360°, and the center of the volute 1 is a funnel-shaped structure with upper and lower layers. The upper part of the main shaft 2 runs through the two-layer funnel-shaped structure of the volute 1, and a circular baffle 2-1 is arranged on the top thereof. The bea...

Embodiment 2

[0051] This embodiment is basically the same as Embodiment 1, except that the flow controller 9 is installed at the water outlet of the volute 1 through a connecting nut 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com