Liquid temperature measuring method

A temperature measurement and liquid technology, which is applied in the field of liquid rapid temperature measurement, can solve the problems of poor corrosion resistance of protective tubes, poor measurement accuracy of thermocouples, slow response, etc., to achieve accurate measurement, fast and accurate measurement, and overcome the effects of slow response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

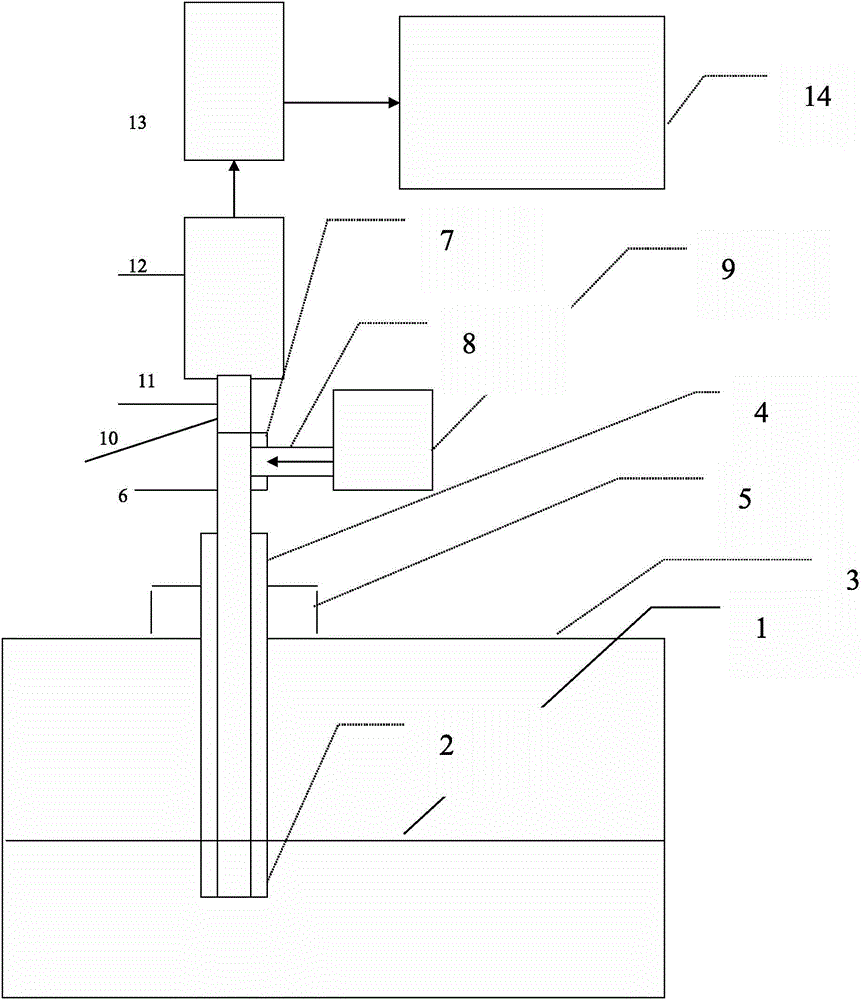

[0017] For the design of this project, see figure 1 It is planned to adopt the fusion of contact temperature measurement and non-contact temperature measurement, and the optical channel protected by air film, to collect the spectral signal of the measured object to know the temperature.

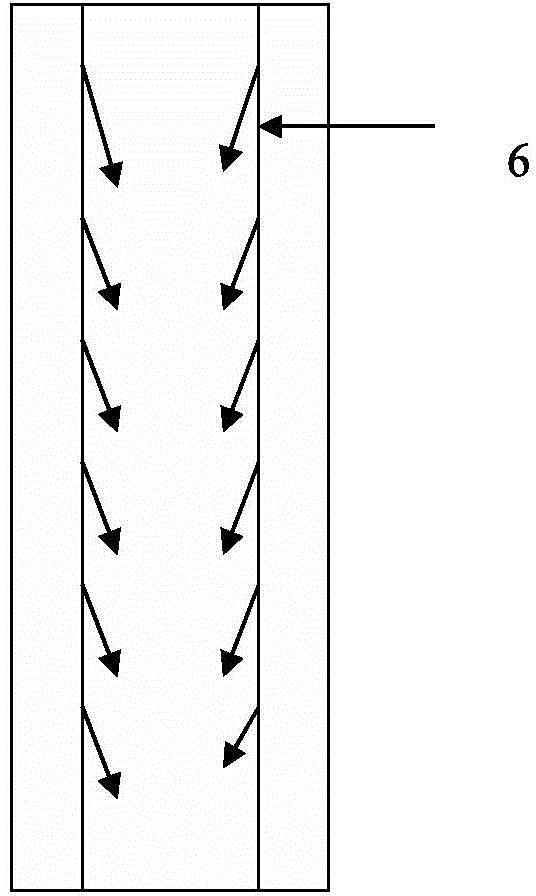

[0018] The system includes a composite ceramic protection tube 4, a one-way stop valve 7, a gas source controller 9, an optical measurement system (6, 10, 11), a spectral thermometer 12, a data recorder 13, and a large-screen display 14. Functions of main components: Composite ceramic protective tube 4 has properties such as corrosion resistance and wall thickness, and is used to protect metal optical blackbody cylinder 6 and prolong service life; metal optical blackbody cylinder 4 is used for the spectrum channel and gas film purge channel of the measured object; The gas film controller 7 is used for gas film generation and control; the one-way stop valve 7 is used for the one-way control of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com